Stereolithography (SLA): Precision in Liquid Resin

The Fundamentals of SLA Technology

Using photopolymerization, stereolithography (SLA) was an innovative fast prototyping technology that could produce very detailed three-dimensional objects. This additive manufacturing technique employs a laser to cure and solidify liquid resin layer by layer, resulting in exceptionally smooth and accurate prototypes. The first step is to use specialist software to slice a 3D model into tiny layers. As the laser traces each layer's cross-section on the surface of the liquid resin, it hardens, forming a solid piece of the final object.

Advantages and Applications of SLA

Due of its numerous distinct advantages, SLA has become a preferred substitute for rapid prototyping. Perfect for making detailed models, architectural renderings, and exact functional prototypes, it can manufacture parts with an outstanding surface polish and attention to detail.The smooth surface quality of SLA parts often requires minimal post-processing, saving time and resources. A variety of sectors, including healthcare, consumer electronics, and automotive, may benefit from SLA's versatility since it is compatible with a broad spectrum of photopolymer resins. These resins can be transparent, flexible, or biocompatible.

Considerations and Limitations

While SLA excels in producing high-resolution prototypes, it does have some limitations to consider.For bigger items in particular, the procedure may be more tedious than other rapid prototyping options. SLA parts may also be prone to warping or shrinkage if not properly supported during printing, and the photopolymer resins used can be more expensive than materials used in other processes.Even without further treatment, SLA components may not have adequate mechanical qualities and may deteriorate when exposed to ultraviolet radiation, rendering them unfit for practical applications that need parts to last for an extended period of time.

Selective Laser Sintering (SLS): Powder-Based Versatility

Understanding SLS Technology

Selective Laser Sintering (SLS) is a powder-based rapid prototyping process that uses a high-powered laser to selectively fuse particles of polymer powder into a solid object. Unlike SLA, SLS doesn't require support structures, as the unfused powder acts as support for the part being built. The build platform is covered with a small coating of powder to start the process. A laser then traces the cross-section of the object, sintering the powder particles together. The build platform then lowers, a new layer of powder is spread, and the process repeats until the entire object is complete.

Material Versatility and Strength

The fact that SLS can handle a broad variety of materials - from different kinds of nylon and polyamide to, in more sophisticated systems, metal powders - is one of its main selling points. Thanks to its adaptability, working prototypes may be made whose qualities are quite similar to those of the finished product.Superior mechanical qualities, such as high strength-to-weight ratios and exceptional durability, are characteristic of SLS components.Because of this, SLS is an excellent option for rapid prototyping, the creation of functional prototypes, end-use parts, and complicated geometries that would be difficult to produce with conventional processes.

Cost-Effectiveness and Design Freedom

Particularly for low to medium volume manufacturing, SLS provides substantial cost benefits. The lack of required support structures means less material waste and post-processing time.This approach also enables for layering several pieces in a single build, optimizing the usage of the build space and minimizing per-part costs. SLS allows designers greater freedom than any other method. They can construct sophisticated designs, sections that fit together, and internal systems that would be hard or too expensive to make with current technologies.SLS is particularly beneficial in fields like aerospace since it is so versatile in its design. In these fields, it is very crucial to minimize weight and combine parts.

Fused Deposition Modeling (FDM): Accessibility and Affordability

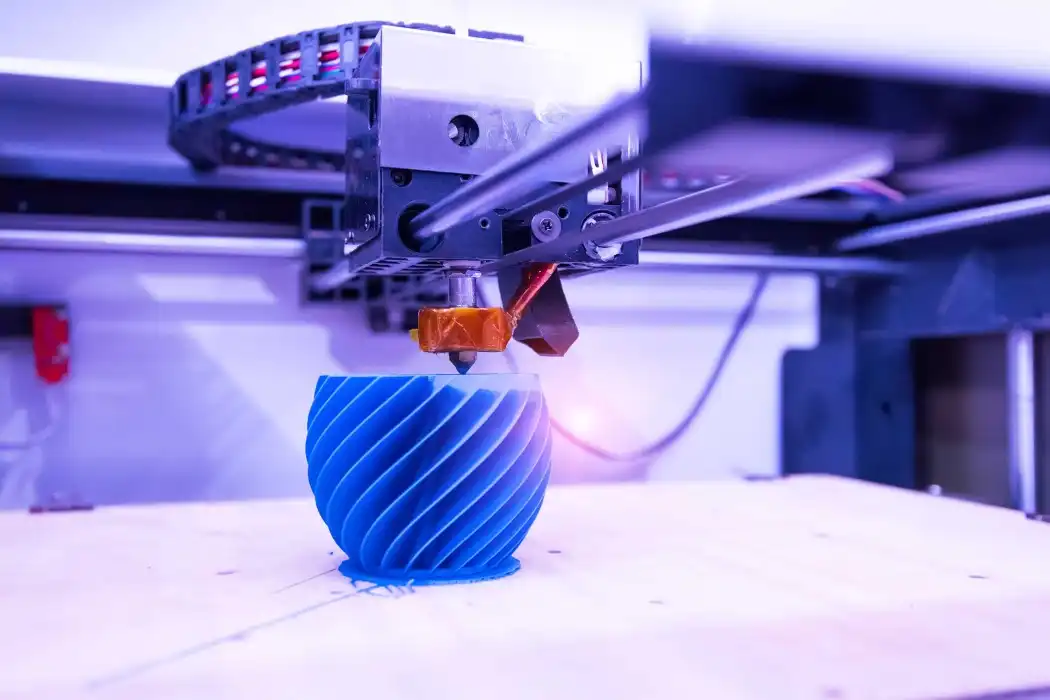

The FDM Process Explained

Fused Deposition Modeling (FDM), also known as Fused Filament Fabrication (FFF), is perhaps the most widely recognized rapid prototyping process due to its popularity in desktop 3D printing. FDM works by extruding thermoplastic filament through a heated nozzle, depositing it layer by layer to build up a three-dimensional object.The first step is to make a 3D model and then cut it into thin layers. The printer then follows this path, extruding molten plastic to create each layer. As each layer cools and solidifies, it bonds with the layer beneath it, gradually forming the complete object.

Material Options and Mechanical Properties

FDM technology can work with a variety of thermoplastic materials, including ABS, PLA, PETG, and more specialized filaments like nylon, TPU (flexible), and even composite materials containing wood or metal particles. This range of materials allows for the rapid prototyping creation of prototypes with varying properties, from rigid and durable to flexible and impact-resistant. While FDM parts may not achieve the same level of detail or surface smoothness as SLA or SLS, they can still produce functional prototypes suitable for testing form, fit, and basic functionality. The layer-by-layer nature of FDM also allows for the incorporation of different materials or colors within a single print, enabling multi-material prototypes.

Cost-Effectiveness and Rapid Iteration

One of the nicest things about FDM is that it is cheap and simple to find.. Rapid prototyping is now accessible to individuals, small enterprises, and huge organizations equally because to the wide range of price ranges for FDM printers, from cheap desktop versions to industrial-grade equipment.The relatively low cost of materials and equipment makes FDM an excellent choice for rapid iteration during the design process. Designers can quickly produce multiple versions of a prototype, test them, and make improvements without incurring significant costs.Improved final designs and shorter product launch times are possible outcomes of this iterative process.

Conclusion

In a rapid prototyping setting, you have access to a plethora of technologies, each with its own benefits and possible applications.The production of high-detail, smooth-surface prototypes is where stereolithography truly shines. The design flexibility and material variety made possible by Selective Laser Sintering are unmatched. Iterative design procedures may be made more accessible and cost-effective with Fused Deposition Modeling.Understanding these typical rapid prototyping techniques and selecting the most appropriate technology for one's needs may help product developers in many sectors speed up the creative process and enhance product quality.

Explore Top Rapid Prototyping Methods with Trusted Supplier | BOEN

For low-volume manufacture and high-quality prototypes in both plastic and metal, BOEN Prototype is the company to call. Automotive, medical device, aerospace, and consumer electronics are just a few of the many fields in which we have extensive experience.With our state-of-the-art CNC machining, rapid injection molding, and 3D printing capabilities, we provide comprehensive solutions for product development.Even the most difficult prototype problems are within our team's capabilities, thanks to our vast expertise and integrated manufacturing procedures. Take advantage of BOEN's assured quality and quick turnaround times. Send an email to contact@boenrapid.com if you would like further details on the services we offer.

References

1. Johnson, A. (2022). "Advancements in Rapid Prototyping Technologies". Journal of Manufacturing Engineering, 45(3), 112-125.

2. Smith, B., & Brown, C. (2021). "Comparative Analysis of SLA, SLS, and FDM for Functional Prototyping". Rapid Prototyping Journal, 27(2), 301-315.

3. Garcia, M. et al. (2023). "Material Considerations in Rapid Prototyping Processes". Advanced Materials and Processes, 181(4), 22-29.

4. Thompson, R. (2022). "Cost-Benefit Analysis of Rapid Prototyping Methods in Product Development". International Journal of Production Economics, 244, 108381.

5. Lee, K., & Chen, Y. (2021). "Design for Additive Manufacturing: Opportunities and Challenges". Computer-Aided Design and Applications, 18(5), 1033-1055.

6. Wilson, J. (2023). "The Future of Rapid Prototyping: Trends and Innovations". Additive Manufacturing, 52, 102705.