When it comes to manufacturing precision parts, two technologies stand out: 3D printing and CNC machining. Although they are similar in many ways, their processes, materials, pricing, and uses are quite different. 3D printing, an additive manufacturing method, builds objects layer by layer from digital designs. In contrast, CNC machining is a subtractive process that cuts away material from a solid block. While 3D printing excels in creating complex geometries and is cost-effective for small batches, CNC machining offers superior precision, a wider range of materials, and is more suitable for larger production runs. Cost-wise, 3D printing typically has lower setup costs but higher per-unit costs, whereas CNC machining involves higher initial setup costs but becomes more economical for larger quantities.

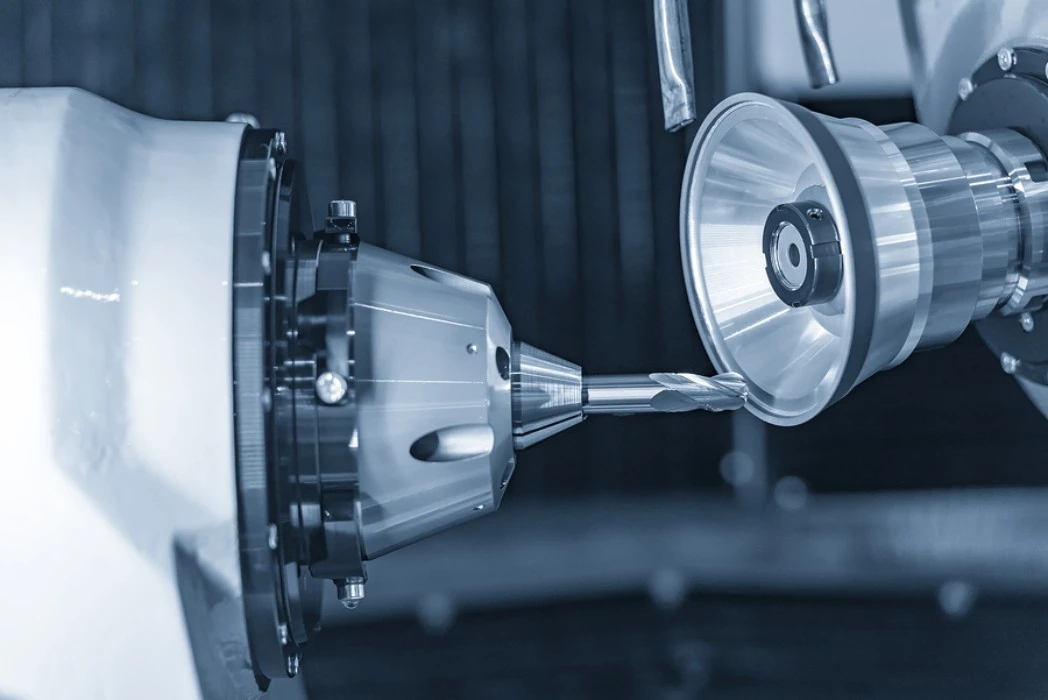

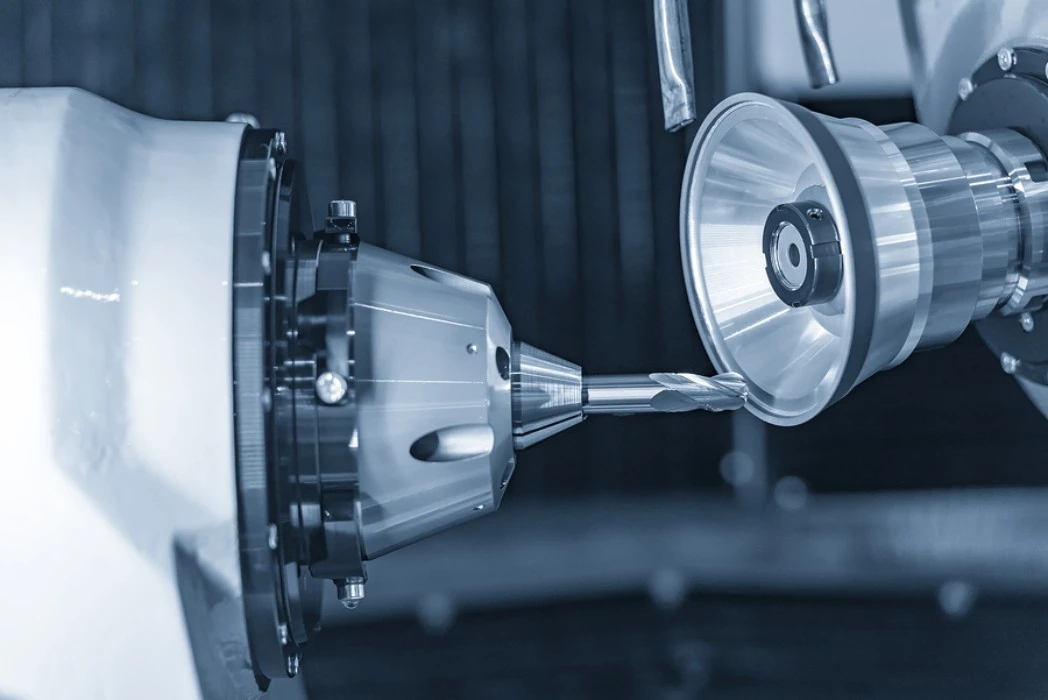

The Intricacies of CNC Machining

CNC machining is a subtractive manufacturing process that uses computer-controlled machines to remove material from a solid block or workpiece. Because of its long history of reliability and consistency, this technology has served as a foundation for contemporary production. The process begins with a CAD (Computer-Aided Design) file, which is then translated into a set of instructions for the CNC machine.

Milling, turning, drilling, and grinding are just a few of the many tasks that CNC machines are capable of. Metals, polymers, and composites are just a few of the many materials that these machines are capable of processing. Because of its adaptability, computer numerical control machining is well-suited for both small- and large-scale manufacturing.

Producing components with very fine tolerances is a major strength of CNC machining. Industries that rely on absolute precision, including aerospace, automotive, and medical device manufacturing, make extensive use of it because to its pinpoint accuracy. Furthermore, using CNC machining, you may get very smooth surfaces with little to no post-processing needed.

Comparing Production Processes

The fundamental difference between 3D printing and CNC machining lies in their approach to creating parts. 3D printing builds up material, while CNC machining removes it. As a result of this differentiation, their manufacturing procedures are very different.

3D printing typically requires less setup time and can start producing parts almost immediately after receiving the digital file. It's also more flexible when it comes to design changes, as modifications can be made quickly in the digital model. However, the layer-by-layer process can be slower for larger parts and may result in visible layer lines that require post-processing.

CNC machining, on the other hand, often requires more initial setup time. Tools need to be selected and programmed, and the workpiece must be properly secured. However, once set up, CNC machines can produce parts rapidly and with high consistency. The subtractive nature of CNC machining also means that it can achieve better surface finishes directly from the machine, often requiring less post-processing than 3D printed parts.

Material Considerations and Capabilities

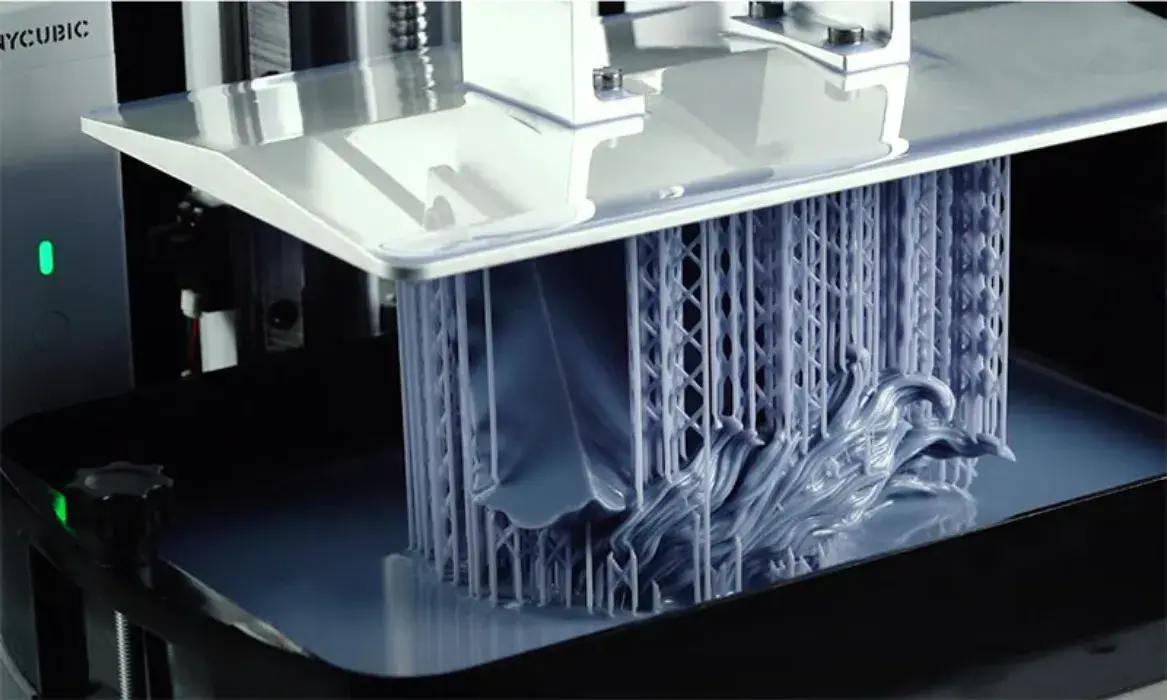

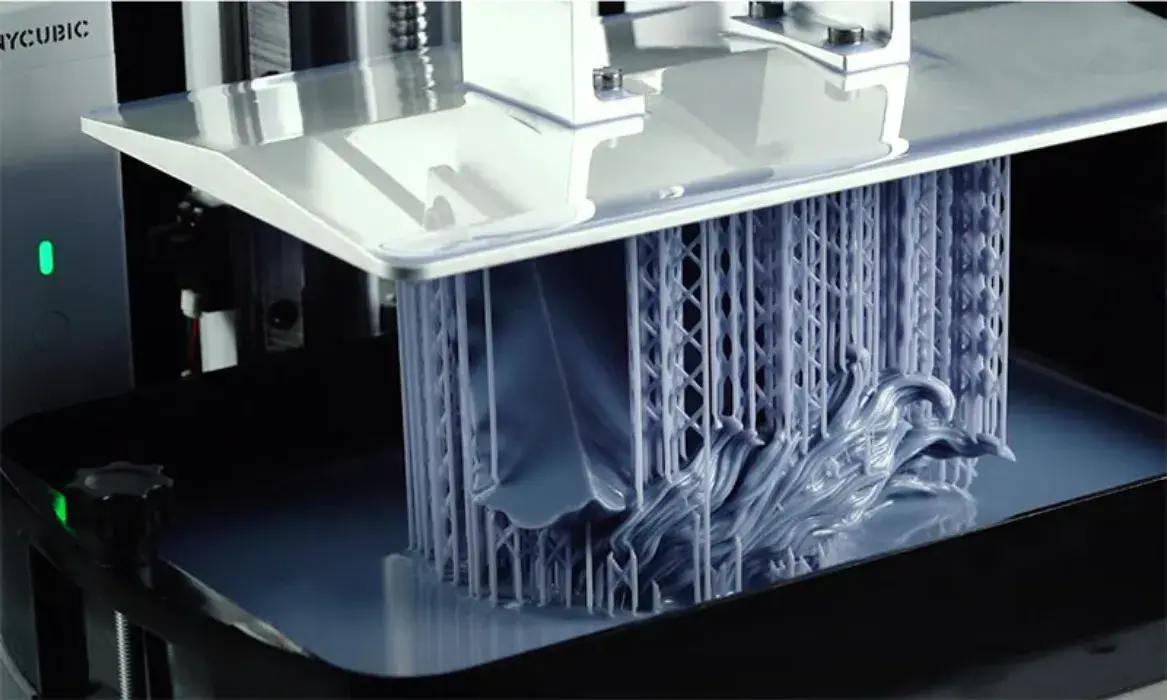

3D Printing Materials and Their Properties

Modern 3D printing technology can handle a wide variety of materials, each with its own set of advantages and disadvantages.Common materials include thermoplastics like ABS and PLA, which are popular in FDM printing for their ease of use and affordability.Prototypes and non-load-bearing components may be made using these materials.

More advanced 3D printing technologies like SLA and SLS can work with specialized resins and powders. The exceptional detail and flawless surfaces that SLA resins are capable of producing make them perfect for use in dentistry or jewelry applications. The use of nylon powders allows SLS to create durable, functional parts that are ideal for the end product.

The aerospace and medical implant sectors are among the first to embrace metal 3D printing, which is still in its infancy. Technologies like Direct Metal Laser Sintering (DMLS) can work with metals such as titanium, aluminum, and stainless steel, producing complex parts with internal structures that would be impossible to machine traditionally.

CNC Machining Materials and Their Characteristics

CNC machining stands out for its ability to work with an extensive range of materials, from soft plastics to hardened steels. Because of its versatility, it may be used in a wide range of industries. Materials such as aluminum, in its many grades, are often used because they are lightweight, strong, and easy to machine. Steels, from mild to tool steel, are used for parts requiring high strength and durability.

Plastics like ABS, POM (Delrin), and PEEK are also frequently machined, especially for applications requiring specific chemical resistance or electrical properties. CNC machining can even work with more exotic materials like titanium for aerospace applications or medical-grade plastics for healthcare devices.

The capacity to handle materials in their finished form is a major benefit of CNC machining. Unlike 3D printing, where parts might require post-processing to achieve full strength, CNC machined parts typically have their full material properties right off the machine. This makes CNC machining particularly suitable for producing functional, end-use parts that need to withstand significant stresses or harsh environments.

Comparing Material Capabilities and Limitations

When comparing the material capabilities of 3D printing and CNC machining, each technology has its strengths and limitations. 3D printing excels in creating parts with complex internal geometries and can work with materials that are difficult to machine, like certain ceramics. It's also possible to print multiple materials in a single part, which can be challenging with CNC machining.

However, CNC machining generally offers superior material properties and consistency. Machined parts typically have better structural integrity, as they're created from solid blocks of material rather than built up layer by layer. Because of this, CNC machining is the way to go for components with high stress tolerance or those that need exact material properties.

In terms of surface finish, CNC machining usually produces smoother surfaces directly from the machine, while 3D printed parts often require post-processing to achieve a comparable finish. On the other hand, 3D printing can create textures and surface details that would be difficult or impossible to machine.

Cost Analysis: 3D Printing vs CNC Machining

Initial Setup and Equipment Costs

The initial costs for 3D printing and CNC machining can vary significantly. Entry-level 3D printers are relatively affordable, with desktop FDM printers starting at a few hundred dollars. Due to the low entry barrier, 3D printing is now within reach of enthusiasts and small enterprises. However, industrial-grade 3D printers, especially those capable of working with metals or high-performance polymers, can cost hundreds of thousands of dollars.

CNC machines, on the other hand, typically have a higher initial cost. A basic CNC mill or lathe can cost tens of thousands of dollars, while advanced multi-axis machines can run into hundreds of thousands or even millions of dollars. This higher upfront cost is often offset by the machine's versatility and ability to handle larger production volumes.

The machines alone aren't enough to power either technology; supplementary hardware and software are also necessary. For 3D printing, this might include post-processing equipment like curing stations or finishing tools. CNC machining often requires a more extensive set of cutting tools, fixtures, and potentially additional software for complex part programming.

Per-Unit Production Costs

When it comes to per-unit costs, the economics of 3D printing and CNC machining can differ dramatically depending on the production volume. 3D printing generally has lower setup costs for each new part, as it doesn't require tooling or extensive programming. This makes it cost-effective for small batches or one-off prototypes.

However, the per-unit cost for 3D printing remains relatively constant regardless of quantity. Material costs for 3D printing can also be higher, especially for specialized resins or metal powders. Another factor that might drive up prices for higher quantities is the slower manufacturing pace of 3D printing.

CNC machining, while often having higher setup costs due to programming and tooling, becomes more economical as production volume increases. The cost per part decreases significantly with larger quantities as the initial setup costs are spread over more units. Material costs for CNC machining are often lower, especially when working with common metals or plastics.

The cost of labor is another consideration. 3D printing typically requires less skilled labor for operation but may need more post-processing work. CNC machining often requires more skilled operators, but the parts usually need less finishing work.

Long-Term Cost Considerations

Several considerations enter into the analysis of 3D printing vs CNC machining in terms of long-term expenses. 3D printers generally have lower maintenance costs and fewer moving parts that can wear out. But for some prints, they could need more frequent material changes and calibration.

CNC machines, while more robust, can have higher maintenance costs due to their complexity. They require regular tool replacements and occasional major component overhauls. Nevertheless, they might be a more adaptable investment in the long run due to their durability and versatility in handling various materials and component sizes.

Energy use is yet another factor to think about. 3D printers, especially those working with plastics, generally consume less power than CNC machines. However, industrial 3D printers, particularly metal printers, can have significant energy requirements.

Ultimately, the most cost-effective choice depends on the specific application, production volume, and types of parts being manufactured. Combining the two technologies is usually the most adaptable and economical option for companies with varied production demands.

Conclusion

When it comes to contemporary production, 3D printing and CNC machining are two distinct processes with their own set of benefits. Ideal for small quantities and inventive designs, 3D printing excels in quick prototyping, complicated geometries, and personalization. CNC machining, with its precision, material versatility, and scalability, remains the go-to for high-volume production and parts requiring tight tolerances. In the end, factors like material requirements, manufacturing volume, and cost will determine which of these technologies is best for a given project. The most complete solution, given the ever-changing nature of production, is often a combination of the two approaches, enabling companies to capitalize on the advantages of both technologies.

Cost-Effective CNC Machining from Expert Manufacturer | BOEN

At BOEN, we specialize in delivering high-quality CNC machining services for prototypes and low-volume production. Our progressed CNC innovation guarantees exactness, effectiveness, and cost-effectiveness over a wide run of materials, counting metals and plastics. The capacity to oversee complicated plans, tall accuracy, and fast turnaround times are our solid suits. Our expertise extends to various industries, including automotive, medical devices, aerospace, and consumer electronics. With our state-of-the-art facilities and skilled team, we offer comprehensive solutions from CAD design to finished products. For expert CNC machining services tailored to your specific needs, contact us at contact@boenrapid.com.

1. Gibson, I., Rosen, D., & Stucker, B. (2015). Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing. Springer.

2. Groover, M. P. (2020). Fundamentals of Modern Manufacturing: Materials, Processes, and Systems. John Wiley & Sons.

3. Attaran, M. (2017). The rise of 3-D printing: The advantages of additive manufacturing over traditional manufacturing. Business Horizons, 60(5), 677-688.

4. Kalpakjian, S., & Schmid, S. R. (2014). Manufacturing Engineering and Technology. Pearson.

5. Gebhardt, A., & Hötter, J. S. (2016). Additive Manufacturing: 3D Printing for Prototyping and Manufacturing. Carl Hanser Verlag GmbH Co KG.

6. Diegel, O., Nordin, A., & Motte, D. (2019). A Practical Guide to Design for Additive Manufacturing. Springer.