Understanding the Fundamentals: 3D Printing and CNC Machining

The Basics of 3D Printing Technology

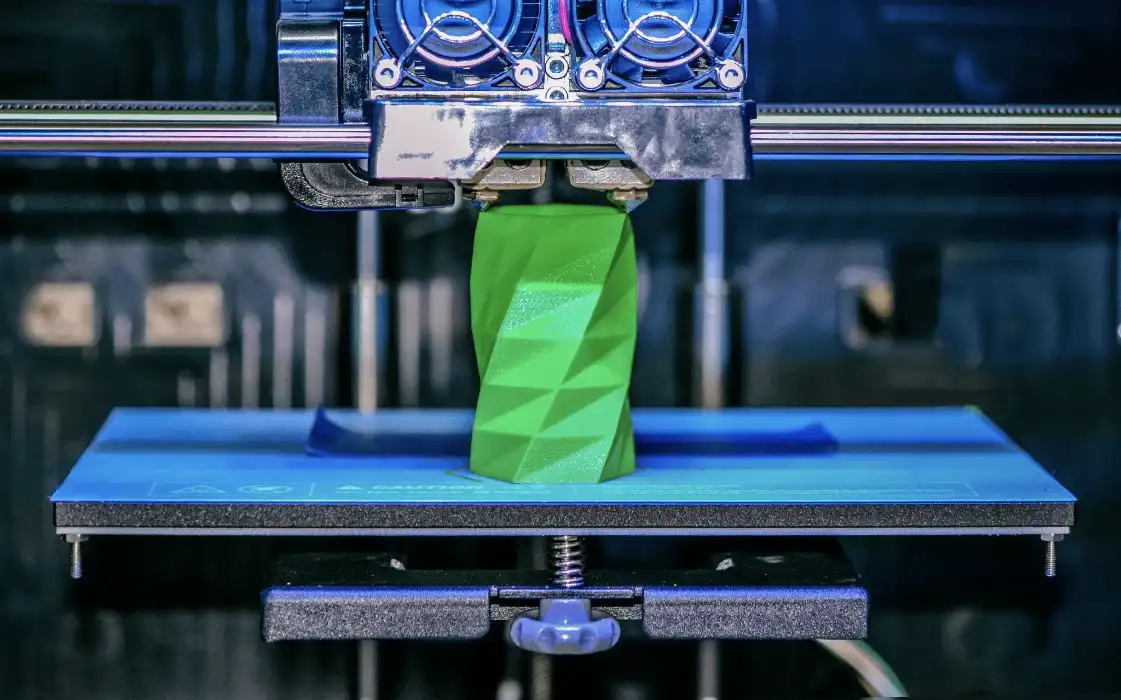

3D printing, also known as additive manufacturing, creates objects by depositing materials layer by layer. The first step is to use specialist software to slice a 3D digital model into tiny layers. The printer then builds the object by adding material according to these layers. Various 3D printing technologies exist, including Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS), each with its own strengths and limitations.

The Mechanics of CNC Machining

Computer Numerical Control (CNC) machining is a subtractive manufacturing process where material is removed from a solid block to create the desired shape. CNC machines are controlled by precise computer programs that guide cutting tools to shape the workpiece. This technology can work with a wide range of materials, including metals, plastics, and composites. CNC machining encompasses various processes such as milling, turning, drilling, and routing, allowing for high precision and repeatability in part production.

Key Differences in Approach and Application

The fundamental difference between 3D printing and CNC machining lies in their approach to creating parts. 3D printing builds up material, while CNC machining removes it. This discrepancy causes variations in the degree of design freedom, the amount of material wasted, and the rate of manufacturing. 3D printing excels in creating complex internal structures and geometries that would be difficult or impossible with traditional machining. However, CNC machining often provides superior surface finish and tighter tolerances, making it preferred for many end-use applications.

Comparing 3D Printing and CNC Machining for Prototyping

Speed and Cost Considerations in Prototyping

In the realm of prototyping, speed is often crucial, and 3D printing generally has the edge. Without equipment or significant setup, it enables quick design iterations. The development time and costs may be drastically reduced with this rapid turnaround, particularly for items that are complicated or bespoke. CNC machining, while potentially slower for one-off prototypes, becomes more cost-effective as quantities increase. It's important to consider not just the production time, but also the post-processing requirements, which can be more extensive for 3D printed parts.

Material Options and Limitations

CNC machining offers a broader range of material options, including metals, plastics, and composites. When prototyping components that need to reflect the material qualities of the finished product, this adaptability is invaluable. 3D printing, while continually expanding its material palette, still has limitations, especially in metal printing. Parts with gradient characteristics and multi-material prototypes are particularly difficult to make using conventional machining techniques; however, 3D printing makes short work of these problems.

Accuracy and Surface Finish in Prototypes

When it comes to accuracy and surface finish, CNC machining typically outperforms 3D printing, especially for end-use parts. CNC machines can achieve tighter tolerances and smoother surfaces right off the machine. 3D printed parts often require post-processing to achieve a comparable finish. However, the layer-by-layer nature of 3D printing allows for the creation of intricate internal features that would be difficult or impossible to machine. Considering aspects like internal complexity, surface quality, and dimensional accuracy, the decision between the two is often dictated by the prototype's unique needs.

Evaluating 3D Printing and CNC Machining for End-Use Parts

Durability and Strength of Produced Parts

For end-use parts, durability and strength are paramount. CNC machined parts generally exhibit superior mechanical properties due to the use of solid materials and the absence of layer lines that can create weak points. Parts that are subject to significant stress or are located in tough locations are better suited for CNC machining because of this. 3D printed parts, particularly those made with advanced materials and technologies like selective laser sintering (SLS), can achieve impressive strength-to-weight ratios. Nevertheless, there are situations when they won't measure up to machined parts, particularly when metal is involved.

Scalability and Production Volume Considerations

When it comes to scaling production, CNC machining has a distinct advantage. Once a CNC program is set up, it can produce identical parts with high efficiency, making it ideal for medium to large production runs. The cost per part typically decreases as volume increases. 3D printing, while excellent for customization and small batches, can become less economical at higher volumes due to slower production speeds and the need for multiple machines to scale up. One advantage of digital inventory management is the fact that 3D printing can create on-demand items without tooling expenditures.

Post-Processing Requirements and Final Quality

Post-processing requirements can significantly impact the overall production time and cost. CNC machined parts often require minimal post-processing, with many parts ready for use straight off the machine. To get the quality and qualities you want out of 3D printed items, however, you usually have to do extra procedures like smoothing the surface, removing supports, or even heat treating them. These post-processing requirements, however, are being reduced as 3D printing technology develop. The final quality of end-use parts is often higher with CNC machining, particularly in terms of dimensional accuracy and surface finish, though 3D printing continues to close this gap, especially in applications where internal complexity is valued over external finish.

Conclusion

Both 3D printing and CNC machining have their places in modern manufacturing. In the early phases of product development, 3D printing is crucial due to its excellence in quick prototyping, complicated geometries, and personalization. Many end-use parts, particularly those demanding high strength and accuracy, continue to be machined using computer numerical control (CNC) technology because to its accuracy, material diversity, and scalability. Combining the benefits of 3D printing with CNC machining is becoming more and more apparent to organizations as the optimal solution to meet their development and production needs. The best features of both systems are used in this hybrid approach. It is important to understand the specific needs of each project in order to choose the appropriate technology.

CNC Machining for End-Use Parts: Precision Guaranteed | BOEN

At BOEN, we specialize in high-precision CNC machining for prototypes and low-volume production. Because it ensures unrivaled accuracy and repeatability, our outstanding CNC technology is relied upon by a great number of industries for end-use components. Metals and plastics are only two of the many materials we provide, and our expert team can handle complex shapes with tight tolerances. BOEN's CNC services provide quick turnaround times, cost-effective solutions for small runs, and the ability to scale up production seamlessly. We give components that coordinate the most rigid prerequisites since we are committed to quality and development. For your another venture, believe BOEN to bring your plans to life with exactness and brilliance. Contact us at contact@boenrapid.com to learn more about our CNC machining capabilities.