Additive Manufacturing vs CNC Machining: A Complete Buyer’s Guide

Your next project's choice between CNC machining and additive manufacturing depends on a number of factors, including complexity, volume, schedule, and material qualities. Rapid prototyping, intricate geometries, and low-volume production with cheap setup costs are areas where additive manufacturing shines. Superior surface finishes, precise tolerances, and tested material qualities are all provided by CNC machining for useful components. Knowing these factory automation technologies may help you speed up time-to-market, save costs, and improve your development process for applications in electronics, automotive, medical, and aerospace.

Understanding the Core Technologies: Digital Fabrication vs Traditional Machining

The advent of layer-by-layer fabrication techniques has drastically changed the industrial scene. In stark contrast to subtractive manufacturing methods, these digital fabrication systems construct items using CAD modeling data.

Three fundamental differences define these technologies:

- Material approach: Additive builds up material progressively

- Design freedom: Complex internal geometries become achievable

- Tooling requirements: Digital processes eliminate traditional tooling needs

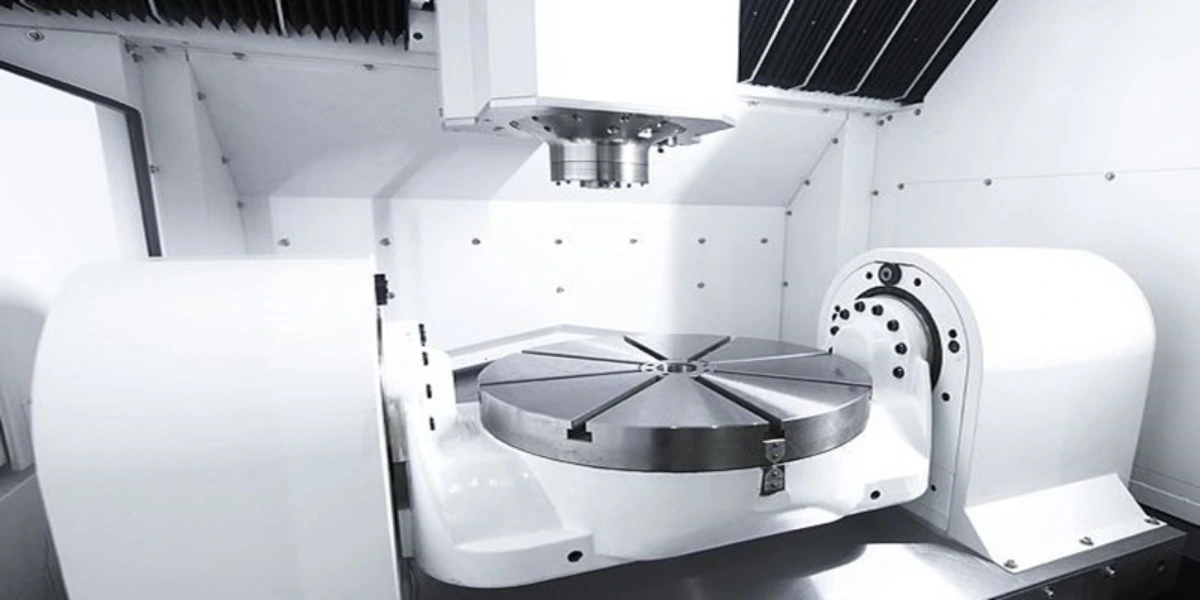

CNC machining uses cutting tools to extract material from solid blocks. Superior surface quality and accuracy are produced by this subtractive method. The method has shown dependability in a variety of materials, including composites, metals, and polymers.

Additive manufacturing works better if you want lightweight structures or intricate interior channels. CNC machining becomes the best option if you need tight tolerances and excellent surface polish.

Binder jetting, selective laser melting, and material extrusion are some of the technologies used in modern 3D printing. Each approach works well with various materials and applications. In the aerospace and medical industries, where customisation and weight reduction are crucial, metal additive manufacturing has become more popular.

Speed and Lead Times: Rapid Prototyping Advantages

Time-to-market pressures drive manufacturing decisions across industries. Both technologies offer distinct speed advantages depending on project requirements and complexity levels.

Additive manufacturing lead times typically range from hours to days:

- Simple prototypes: 2-8 hours print time

- Complex assemblies: 1-3 days including post-processing

- No tooling preparation required

- Immediate design iterations possible

CNC machining involves setup time but delivers consistent production speeds. Simple parts machine within hours while complex components may require multiple operations spanning several days.

Comparative speed data shows distinct patterns:

- Quantities of the prototype (1–10 parts): 60–80% more wins with additive

- 50–500 pieces in medium batches: CNC starts to compete

- Large quantities (1000+ parts): CNC has a major advantage.

Additive manufacturing speeds up development timelines if you want single prototypes or rapid design validation. CNC machining offers predictable throughput if you need reliable production rates for well-established designs.

The build volume limitations of 3D printing systems can impact larger components. Most desktop systems accommodate parts up to 200mm cubic while industrial machines handle much larger assemblies.

Precision and Surface Quality: When Tolerances Matter

The level of accuracy required for manufacturing varies greatly depending on the application. Tight tolerances and superior surface finishes are required for automotive, medical, and aerospace components.

CNC machining typically achieves:

- Dimensional accuracy: ±0.025mm (±0.001")

- Surface roughness: Ra 0.4-3.2μm

- Consistent repeatability across production runs

- No support structure marks or layer lines

Additive manufacturing precision varies by technology:

- SLA systems: ±0.1mm accuracy, Ra 1-5μm surface

- SLS polymer printing: ±0.3mm accuracy, Ra 8-15μm surface

- Metal selective laser melting: ±0.1mm accuracy, Ra 5-20μm surface

The quality of the finished product is greatly impacted by post-processing. Although they increase time and expense, machining, sanding, and chemical smoothing enhance surface properties.

CNC machining offers excellent consistency if you want precise tolerances of less than ±0.1mm. For the majority of applications, additive manufacturing is adequate if you can tolerate somewhat looser standards for quicker prototyping.

In 3D printing, support structures produce surface flaws that must be eliminated. Strategic part orientation maximizes construction efficiency while reducing support needs.

Material Options and Properties: Choosing the Right Substrate

Material selection profoundly influences part performance, durability, and application suitability. Both manufacturing approaches offer extensive material libraries with distinct characteristics.

CNC machining accommodates virtually any machinable material:

- Metals: copper, brass, titanium, steel, and aluminum

- ABS, nylon, PEEK, POM, and polycarbonate are examples of plastics.

- Composites: Materials reinforced with fiberglass and carbon fiber

- Verified material qualities from large quantities

Additive manufacturing materials continue expanding rapidly:

- Polymer printing: PLA, ABS, PETG, nylon, TPU flexibles

- Metal printing: Stainless steel, aluminum, titanium, Inconel

- Specialty materials: Ceramics, biocompatible resins, conductive filaments

- Material properties may differ from bulk equivalents

Key considerations for material performance:

- Strengths: Full material qualities are maintained in CNC parts

- Temperature resistance varies greatly depending on the procedure.

- Chemical compatibility is crucial for applications in medicine and automobiles.

- Biocompatibility is essential for the creation of medical devices.

CNC machining provides more alternatives if you want vast material selections and established material qualities. Additive manufacturing offers specific advantages if you need specialty materials like complicated metal alloys or flexible polymers.

Metal sintering procedures Compared to wrought materials, 3D printing may produce distinct microstructures. Accurately predicting part performance is made easier by being aware of these variations.

Cost Analysis: Balancing Budget and Requirements

Manufacturing costs encompass material expenses, labor time, equipment usage, and post-processing requirements. Understanding cost structures helps optimize budget allocation.

Additive manufacturing cost structure:

- High material costs per unit weight

- Minimal setup or tooling expenses

- Labor costs concentrated in post-processing

- Equipment time scales with part volume and complexity

CNC machining cost structure:

- Lower raw material costs

- Significant setup time for complex parts

- Skilled operator requirements

- Tooling wear and replacement costs

Cost comparison data across typical scenarios:

| Volume | Simple Parts | Complex Parts |

|---|---|---|

| 1-10 units | Additive 40% lower | Additive 70% lower |

| 50-100 units | Nearly equal | Additive 30% lower |

| 500+ units | CNC 60% lower | CNC 40% lower |

Additive manufacturing offers financial benefits if you want small volumes or intricate geometries. With simpler designs and larger volume requirements, CNC machining becomes more cost-effective.

By producing lightweight, highly durable designs that are not achievable with conventional production, topology optimization methods optimize the advantages of additive printing.

Industry-Specific Applications and Use Cases

Depending on particular needs, legal restrictions, and performance requirements, several sectors make use of different production methods.

Automotive sector applications:

- Rapid prototyping for design validation

- Custom tooling and fixtures

- Lightweight components for electric vehicles

- Complex intake manifolds and cooling channels

Medical and healthcare uses:

- Patient-specific implants and prosthetics

- Surgical guides and anatomical models

- Biocompatible device housings

- Ergonomic testing samples

Aerospace and UAV applications:

- High-strength titanium components

- Lightweight structural brackets

- Complex internal cooling passages

- Rapid certification prototype development

Consumer electronics applications:

- Aesthetic prototype development

- Custom enclosure fabrication

- Heat dissipation components

- Ergonomic testing models

CNC machining often offers more straightforward certification pathways if you operate in regulated areas like medical devices. Additive manufacturing speeds up development timelines for consumer items that need quick design revisions.

Repair and modification of existing components are made possible by direct energy deposition methods, which are very useful in aircraft maintenance applications.

Making the Right Choice: Decision Framework

Selecting optimal manufacturing approaches requires systematic evaluation of project requirements, constraints, and priorities. This framework guides decision-making processes.

Primary evaluation criteria:

- Quantity requirements: Volume directly influences cost-effectiveness

- Geometric complexity: Internal features favor additive approaches

- Timeline constraints: Rapid prototyping needs differ from production

- Quality specifications: Tolerance and surface finish requirements

- Material properties: Functional requirements versus available options

Decision matrix considerations:

- Prototype development: Additive manufacturing advantages

- Low-volume production: Technology choice depends on complexity

- High-volume manufacturing: CNC machining typically wins

- Complex geometries: Additive manufacturing excels

- High precision: CNC machining delivers consistently

If you need quick design validation with moderate precision, additive manufacturing accelerates development. If you require production-quality parts with tight tolerances, CNC machining ensures reliability.

Manufacturing automation continues advancing both technologies. Hybrid approaches combining additive and subtractive processes maximize benefits while minimizing limitations.

BOEN Prototype: Your Trusted Additive Manufacturing Partner

BOEN Prototype delivers comprehensive additive manufacturing solutions tailored to diverse industry requirements. Our extensive capabilities span SLA 3D printing, SLS polymer processing, and metal selective laser melting technologies alongside traditional CNC machining services.

Being a top provider for additive manufacturing, we are aware of how important it is to strike a balance between affordability, quality, and speed. Our skilled engineers direct the choice of materials, optimize designs for production, and guarantee quick turnaround times without sacrificing accuracy.

Contact our specialists at contact@boenrapid.com to discuss your next project requirements and discover how our integrated manufacturing approach accelerates your product development timeline.

References

1. Gibson, I., Rosen, D., Stucker, B., & Khorasani, M. (2021). "Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing, Third Edition." Springer International Publishing.

2. Thompson, M. K., Moroni, G., Vaneker, T., Fadel, G., Campbell, R. I., Gibson, I., & Martina, F. (2016). "Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints." CIRP Annals - Manufacturing Technology, 65(2), 737-760.

3. Singh, R., Kumar, R., Farina, I., Colangelo, F., Feo, L., & Fraternali, F. (2019). "Multi-material additive manufacturing of sustainable innovative materials and structures." Polymers, 11(1), 62.

4. Kellens, K., Baumers, M., Gutowski, T. G., Flanagan, W., Lifset, R., & Duflou, J. R. (2017). "Environmental dimensions of additive manufacturing: Mapping application domains and their environmental implications." Journal of Industrial Ecology, 21(S1), S49-S68.

5. Liu, R., Wang, Z., Sparks, T., Liou, F., & Newkirk, J. (2017). "Aerospace applications of laser additive manufacturing." Laser Additive Manufacturing: Materials, Design, Technologies, and Applications, 351-371.

6. Attaran, M. (2017). "The rise of 3-D printing: The advantages of additive manufacturing over traditional manufacturing." Business Horizons, 60(5), 677-688.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.