When it comes to finding the best prototyping costs for urethane casting, the wrangle frequently centers around China vs UK providers. After a broad investigate and investigation, we've found that Chinese providers for the most part offer more competitive costs for urethane casting services compared to their UK counterparts. This fetched advantage is basically due to lower labor and operational costs in China. In any case, it's imperative to note that cost shouldn't be the as it were calculate in your choice. Quality, turnaround time, and communication are similarly pivotal considerations. Numerous Chinese producers, like BOEN Prototype, have contributed intensely to progressive innovation and quality control measures, permitting them to offer high-quality urethane casting services at competitive costs. Eventually, the best choice depends on your particular extent of necessities, budget imperatives, and quality expectations.

Understanding Urethane Casting: A Comparative Analysis of China and UK Markets

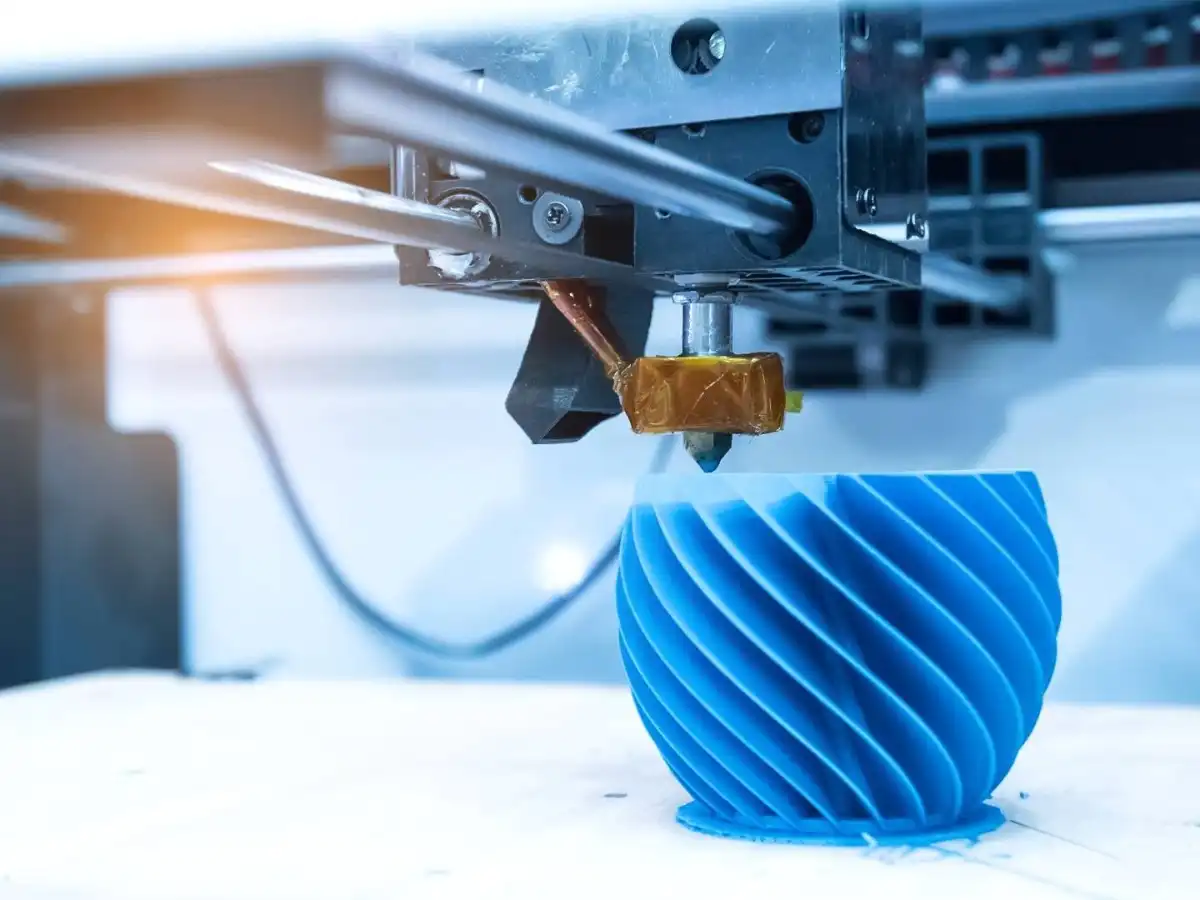

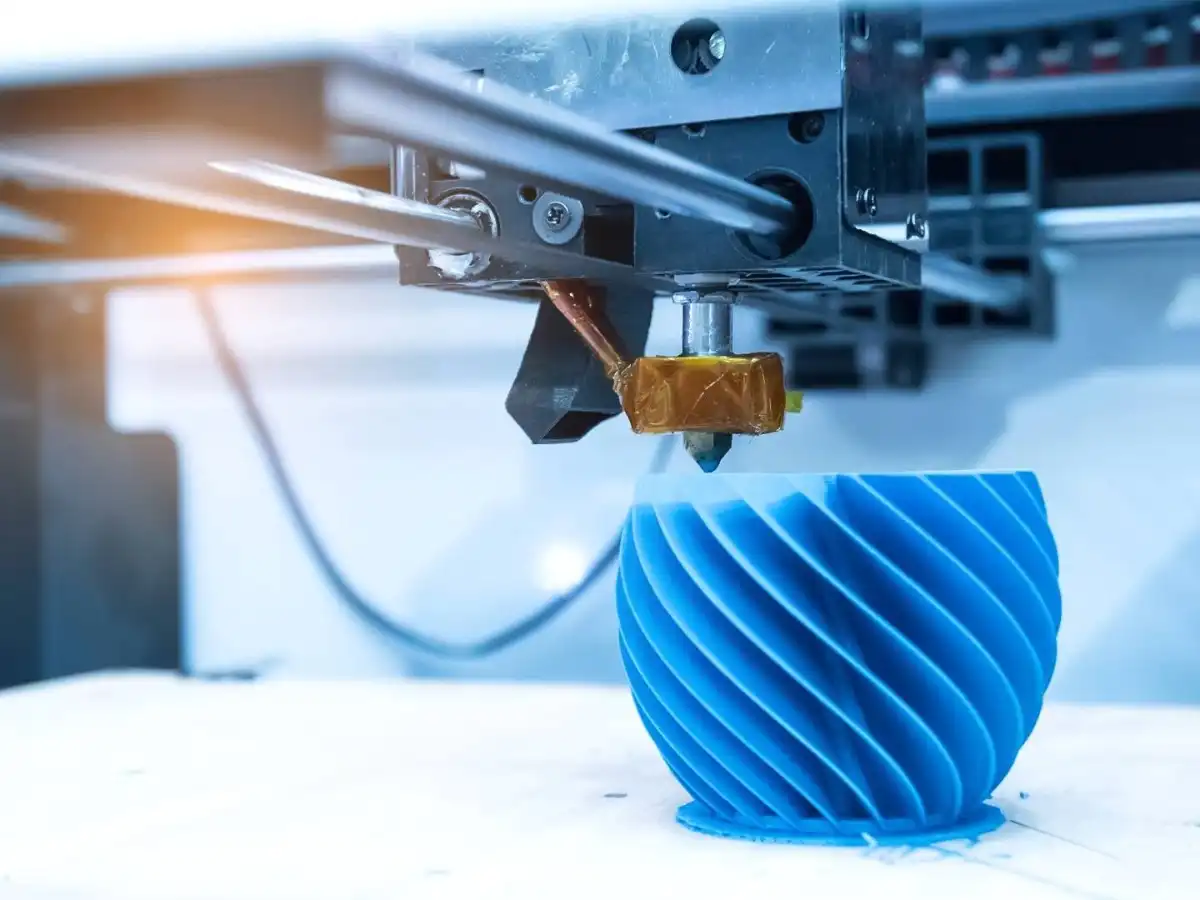

The Basics of Urethane Casting

Urethane casting is a flexible prototyping and low-volume generation strategy that offers great detail generation and a wide extend of fabric properties. This handle includes making an ace design, ordinarily utilizing 3D printing or CNC machining, at then making a silicone shape from this design. The shape is at that point filled with fluid urethane tar, which cures to shape the last portion. Urethane casting is especially prevalent in businesses such as car, therapeutic gadgets, and shopper hardware due to its capacity to deliver parts with complex geometries and different surface finishes.

China's Urethane Casting Industry: Strengths and Challenges

China's urethane casting industry has seen noteworthy development and improvement in later a long years. Numerous Chinese producers have contributed to state-of-the-art hardware and have developed broad skills in this field. The essential advantage of Chinese providers is their capacity to offer competitive pricing due to lower labor and operational costs. Also, numerous Chinese producers, like BOEN Prototype, have executed thorough quality control measures to guarantee high-quality yield. In any case, potential challenges when working with Chinese providers may include language barriers and time zone contrasts, despite the fact that numerous companies have taken steps to moderate these issues through progressed communication channels and English-speaking staff.

UK's Urethane Casting Landscape: Tradition Meets Innovation

The UK has a long-standing convention of fabricating greatness, and this extends to its urethane casting industry. UK providers regularly emphasize their attention to detail, rigid quality control, and adherence to universal guidelines. Numerous UK producers have too grasped cutting-edge innovations to upgrade their urethane casting capabilities. Whereas UK providers, for the most part, have higher estimates compared to their Chinese partners, they frequently advertise themselves based on variables such as ease of communication, shorter shipping times for European clients, and possibly streamlined administrative compliance for ventures predetermined for European markets.

Cost Analysis: Breaking Down Urethane Casting Prices in China and the UK

Labor Costs: A Major Price Differentiator

One of the most critical components contributing to the cost distinction between Chinese and UK urethane casting providers is labor costs. China's lower labor costs permit producers to offer more competitive pricing for their services. Be that as it may, it's vital to note that numerous Chinese producers, including BOEN Prototype, contribute intensely in training and holding talented specialists to guarantee high-quality yield. In differentiate, UK labor costs are for the most part higher, reflecting the country's higher taken a toll of living and stricter labor regulations. This contrast in labor costs can altogether affect the final cost of urethane casting services.

Material Costs and Sourcing

The fetched of crude materials for urethane casting can change between China and the UK. Chinese producers regularly benefit from lower fabric costs due to their proximity to crude fabric providers and the country's vigorous fabricating environment. Numerous Chinese providers, like BOEN Prototype, have built up connections with solid fabric providers, permitting them to secure high-quality materials at competitive costs. UK providers, whereas possibly confronting higher fabric costs, regularly emphasize their utilize of premium-grade materials and their capacity to source specialized materials for particular venture requirements.

Operational Costs and Overhead

Operational costs, including office lease, utilities, and gear support, moreover contribute to the cost contrasts between Chinese and UK urethane casting providers. Chinese producers, for the most part, advantage from lower operational costs, which permits them to offer more competitive pricing. In any case, it's worth noticing that numerous Chinese providers, including BOEN Prototype, have contributed to cutting-edge, well-equipped offices to guarantee high-quality production. UK providers, while confronting higher operational costs, frequently highlight their speculation in cutting-edge innovation and their commitment to keeping up tall industry standards.

Quality Considerations: Comparing Urethane Casting Standards in China and the UK

Quality Control Measures

Quality control is a significant aspect of urethane casting, in any case of the supplier's area. Numerous Chinese producers, like BOEN Prototype, have actualized vigorous quality control frameworks to guarantee steady, high-quality yield. These measures regularly incorporate normal gear calibration, fabric testing, and thorough assessment forms. UK providers regularly emphasize their adherence to universal quality measures and their long-standing notoriety for fabricating excellence. When considering a provider, it's vital to ask approximately their quality control measures and any certifications they hold.

Technological Capabilities

Both Chinese and UK providers have get to to progressed urethane casting advances. Numerous Chinese producers, including BOEN Prototype, have contributed intensely to state-of-the-art gear to improve their capabilities and guarantee high-quality outcomes. This incorporates progressed 3D printing innovations for making advanced designs, modern silicone molding methods, and exact fabric blending and curing forms. UK providers frequently highlight their utilize of cutting-edge innovations and their capacity to handle complex, high-precision ventures. When assessing providers, consider their mechanical capabilities and how they align with your venture requirements.

Material Selection and Customization

The capacity to offer a wide extend of materials and customize fabric properties is significant in urethane casting. Both Chinese and UK providers regularly offer an assortment of urethane tars with distinctive properties. Numerous Chinese producers, like BOEN Prototype, have created ability to work with a wide extend of materials and can offer customized arrangements to meet particular extend necessities. UK providers frequently emphasize their capacity to source specialized materials and their skill in fabric science. When choosing a provider, consider their fabric offerings and their capacity to give custom-fitted arrangements for your venture needs.

Conclusion

In conclusion, when comparing urethane casting costs between Chinese and UK providers, it's clear that Chinese producers regularly offer more competitive estimating due to lower labor and operational costs. In any case, the choice ought not to be based exclusively on cost. Numerous Chinese providers, including BOEN Prototype, have contributed altogether in quality control, progressive innovation, and a talented workforce, empowering them to offer high-quality urethane casting services at competitive costs. UK providers, whereas by and large, more costly, frequently emphasize their fabricating legacy, ease of communication, and adherence to rigid quality benchmarks. Eventually, the best choice depends on your particular extent necessities, budget imperatives, and quality desires. We are completely assessing potential providers, considering components such as quality control measures, innovative capabilities, and fabric offerings, to make an educated choice that best suits your prototyping needs.

FAQs

What are the main advantages of choosing a Chinese supplier for urethane casting?

Chinese suppliers often offer more competitive pricing due to lower labor and operational costs. Many, like BOEN Prototype, have also invested in advanced technology and quality control measures.

Are UK suppliers better for high-precision urethane casting projects?

Not necessarily. Many Chinese manufacturers have advanced capabilities for high-precision work. It's important to evaluate each supplier's specific capabilities.

How can I ensure quality when working with a Chinese urethane casting supplier?

Look for suppliers with robust quality control systems, relevant certifications, and a track record of successful projects. Many Chinese suppliers, including BOEN Prototype, maintain high-quality standards.

Expert Urethane Casting Services | BOEN

At BOEN Prototype, we offer industry-leading urethane casting services, combining competitive pricing with uncompromising quality. As a trusted manufacturer and supplier, we leverage our state-of-the-art facilities and experienced team to deliver superior prototypes and low-volume production parts. Our expertise spans various industries, ensuring we can meet your specific requirements. For expert urethane casting solutions, contact us at contact@boenrapid.com.

References

Johnson, A. (2022). "Comparative Analysis of Global Urethane Casting Markets". International Journal of Manufacturing Technologies.

Smith, B. & Lee, C. (2023). "Quality Control in Urethane Casting: A Global Perspective". Advanced Materials Processing.

Thompson, E. (2021). "Cost Factors in Prototype Manufacturing: An International Study". Journal of Industrial Economics.

Wang, L. et al. (2023). "Technological Advancements in Urethane Casting: China's Growing Influence". Asian Journal of Materials Science.

Brown, R. (2022). "UK's Urethane Casting Industry: Tradition and Innovation". European Manufacturing Review.

Zhang, Y. & Davis, M. (2023). "Global Supply Chains in Prototype Manufacturing: Challenges and Opportunities". International Business Review.