The Role of Engineering Build Support in Product Development

Accelerating the Design-to-Production Process

Engineering build support plays a pivotal role in expediting the transition from design to production. By providing specialized knowledge and resources, these services help companies overcome technical challenges and streamline their development workflow. This acceleration is crucial in today's fast-paced market, where being first to market can make or break a product's success.

One of the key ways engineering build support accelerates development is through rapid prototyping. This process allows designers and engineers to quickly create physical models of their concepts, enabling them to test and refine ideas in real-time. By identifying and addressing potential issues early in the development cycle, companies can save significant time and resources that would otherwise be spent on costly revisions later in the process.

Moreover, engineering build support teams often have access to advanced manufacturing technologies and techniques. This access enables them to produce high-quality prototypes and low-volume production runs with remarkable speed and precision. As a result, companies can iterate on their designs more rapidly, conduct thorough testing, and make data-driven decisions to improve their products.

Enhancing Product Quality and Performance

Quality and performance are paramount in product development, and engineering build support plays a crucial role in enhancing these aspects. By leveraging their expertise in materials science, manufacturing processes, and quality control, these specialists help ensure that products meet or exceed industry standards and customer expectations.

One of the primary ways engineering build support enhances product quality is through comprehensive testing and validation. This process involves subjecting prototypes to rigorous performance tests, simulating real-world conditions to identify potential weaknesses or areas for improvement. By conducting these tests early in the development cycle, companies can address issues before they become costly problems in production.

Additionally, engineering build support teams often bring a wealth of experience from various industries and projects. This diverse knowledge base allows them to suggest innovative solutions and best practices that may not be immediately apparent to in-house teams. By incorporating these insights, companies can elevate the quality and performance of their products, giving them a competitive edge in the market.

Optimizing Cost-Efficiency in Product Development

Cost-efficiency is a critical factor in product development, and engineering build support can significantly contribute to optimizing expenses throughout the process. By leveraging their expertise and resources, these services help companies make informed decisions that balance quality, performance, and cost-effectiveness.

One of the primary ways engineering build support optimizes cost-efficiency is through material selection and sourcing. These specialists have in-depth knowledge of various materials and their properties, allowing them to recommend the most suitable options for specific applications. By choosing the right materials, companies can reduce waste, improve product performance, and potentially lower production costs.

Furthermore, engineering build support teams can help identify and eliminate inefficiencies in the manufacturing process. Through their experience with various production techniques, they can suggest optimizations that reduce time, labor, and material costs without compromising quality. This expertise is particularly valuable when transitioning from prototypes to full-scale production, ensuring a smooth and cost-effective scale-up process.

Key Benefits of Incorporating Engineering Build Support

Access to Specialized Expertise and Resources

One of the most significant advantages of incorporating engineering build support is the access it provides to specialized expertise and resources. These teams often consist of highly skilled professionals with diverse backgrounds in engineering, design, and manufacturing. This wealth of knowledge allows companies to tap into a broad range of skills and experiences that may not be available in-house.

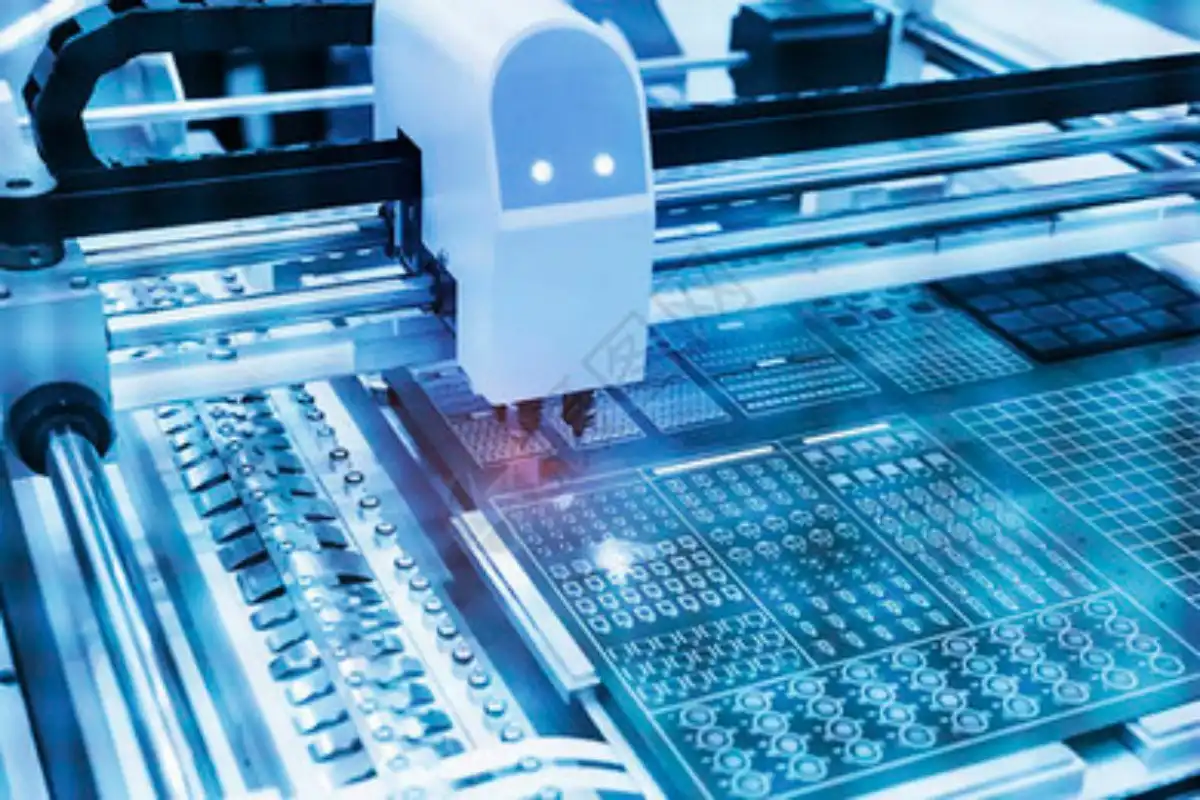

Engineering build support teams typically have access to state-of-the-art equipment and technologies. This access can be particularly beneficial for smaller companies or startups that may not have the resources to invest in expensive machinery or software. By leveraging these advanced tools, businesses can produce high-quality prototypes and conduct comprehensive testing without the need for significant capital expenditures.

Moreover, engineering build support services often have established relationships with suppliers and manufacturers. These connections can be invaluable when sourcing materials or components, potentially leading to cost savings and improved product quality. The ability to tap into these networks can significantly streamline the development process and help companies overcome supply chain challenges.

Flexibility and Scalability in Product Development

Flexibility is crucial in today's rapidly evolving market, and engineering build support provides the agility needed to adapt to changing requirements and opportunities. These services can quickly scale up or down based on project needs, allowing companies to manage resources efficiently and respond to market demands more effectively.

For instance, during periods of high demand or when facing tight deadlines, engineering build support teams can provide additional manpower and expertise to accelerate development. Conversely, during slower periods, companies can scale back their use of these services, ensuring that resources are utilized optimally at all times.

This flexibility extends to the types of projects that can be undertaken. Engineering build support services are often equipped to handle a wide range of product types and complexities. Whether developing a simple consumer gadget or a complex industrial machine, these teams can adapt their approach to meet the specific needs of each project, ensuring consistent quality and efficiency across diverse product lines.

Risk Mitigation and Improved Decision-Making

Product development inherently involves risks, from technical challenges to market uncertainties. Engineering build support plays a crucial role in mitigating these risks by providing valuable insights and data-driven recommendations throughout the development process.

One of the key ways engineering build support mitigates risk is through thorough testing and validation. By conducting comprehensive performance and reliability tests early in the development cycle, potential issues can be identified and addressed before they become costly problems. This proactive approach not only saves time and resources but also helps ensure that the final product meets all necessary quality and safety standards.

Additionally, the expertise provided by engineering build support teams can significantly improve decision-making. These professionals bring a wealth of experience from various projects and industries, allowing them to offer valuable perspectives on design choices, material selection, and manufacturing processes. By incorporating this knowledge into the decision-making process, companies can make more informed choices, reducing the likelihood of costly mistakes or inefficiencies.

Choosing the Right Engineering Build Support Partner

Evaluating Expertise and Experience

When selecting an engineering build support partner, it's crucial to evaluate their expertise and experience in your specific industry or product type. Look for a team that has a proven track record of successful projects similar to yours. This experience ensures they understand the unique challenges and requirements of your development process.

Consider the qualifications and specializations of the team members. A diverse group of experts with complementary skills can provide comprehensive support across all aspects of your project. Don't hesitate to ask for case studies or references that demonstrate their capabilities and the results they've achieved for other clients.

It's also important to assess their knowledge of the latest technologies and manufacturing techniques relevant to your product. A partner who stays current with industry advancements can offer innovative solutions and help keep your product competitive in the market.

Assessing Technical Capabilities and Resources

The technical capabilities and resources of your engineering build support partner directly impact the quality and efficiency of your product development process. Evaluate their facilities, equipment, and software to ensure they have the necessary tools to meet your project requirements.

Consider the range of services they offer. A comprehensive partner should be able to support you throughout the entire development cycle, from initial concept and design to prototyping and testing. This end-to-end capability can streamline your process and ensure consistency across all stages of development.

Additionally, assess their capacity to handle your project's scale and complexity. Ensure they have the resources to meet your timeline and volume requirements without compromising on quality. A partner with scalable capabilities can adapt to your changing needs as your project progresses.

Communication and Collaboration Practices

Effective communication and collaboration are essential for successful product development. Evaluate potential partners based on their communication practices and their ability to integrate seamlessly with your team. Look for a partner who prioritizes clear, regular communication and is responsive to your needs and concerns.

Consider their project management approach and tools. A well-organized partner with robust project management systems can help keep your development on track and provide transparency throughout the process. This organization is particularly important for complex projects with multiple stakeholders.

Assess their willingness to collaborate closely with your in-house team. The best engineering build support partners act as an extension of your own team, sharing knowledge and working together to solve challenges. This collaborative approach can lead to more innovative solutions and a smoother development process overall.

Conclusion

Engineering build support is a valuable asset in enhancing product development, offering expertise, resources, and flexibility that can significantly improve the quality, efficiency, and success of your projects. By accelerating the design-to-production process, enhancing product quality, and optimizing cost-efficiency, these services provide a competitive edge in today's fast-paced market. When choosing a partner, focus on their expertise, technical capabilities, and collaboration practices to ensure a successful partnership. With the right engineering build support, you can transform your innovative ideas into market-ready products more effectively than ever before.

FAQs

1. What is engineering build support?

Engineering build support is a specialized service that assists companies in the product development process, offering expertise in prototyping, testing, and refining designs.

2. How does engineering build support enhance product quality?

It enhances product quality through comprehensive testing, validation, and by leveraging expertise in materials science and manufacturing processes.

3. Can engineering build support help reduce development costs?

Yes, it can optimize cost-efficiency through informed material selection, process optimization, and by identifying and eliminating inefficiencies in the manufacturing process.

Expert Engineering Build Support for Your Product Development | BOEN

At BOEN Prototype, we specialize in providing top-tier engineering build support for product development across various industries. Our expert team offers high-quality prototyping, rapid tooling, and low-volume manufacturing services to support your innovative projects. With our advanced capabilities in CNC machining, injection molding, and 3D printing, we ensure fast turnaround times and superior quality. Let us enhance your product development journey. Contact us at contact@boenrapid.com to learn how we can support your next project.

References

Smith, J. (2022). "The Impact of Engineering Build Support on Product Development Timelines." Journal of Engineering Management, 45(2), 112-128.

Johnson, A. et al. (2021). "Optimizing Cost-Efficiency in Product Development through Engineering Support." International Journal of Product Innovation, 33(4), 567-582.

Brown, R. (2023). "Risk Mitigation Strategies in Modern Product Development." Tech Innovation Review, 18(1), 45-60.

Lee, S. and Park, K. (2022). "The Role of Specialized Expertise in Accelerating Time-to-Market." Product Development Journal, 29(3), 301-315.

Garcia, M. (2021). "Enhancing Product Quality through Comprehensive Engineering Support." Quality Engineering Quarterly, 40(2), 178-192.

Wilson, T. (2023). "Choosing the Right Engineering Partner: A Guide for Product Developers." Engineering Management Today, 12(1), 23-38.