Germany EV Firms: Why Source Aluminum Extrusions from China

German companies that make electric vehicles are looking to China more and more for their aluminum extrusion needs, which makes sense. Because it is cheap, has advanced industrial skills, and a strong supply chain, China is a good place to get high-quality aluminum extrusions. For EV battery boxes, structural frames, and other important parts, these parts are essential. German electric vehicle companies can improve their production methods, cut costs, and stay ahead of the competition in the fast-changing market for electric vehicles by using China's skill in aluminum extrusion.

The Rising Demand for Aluminum Extrusions in the EV Industry

Lightweight Solutions for Improved EV Performance

In the electric vehicle business, aluminum extrusions are very important because they make strong but lightweight parts that are needed to make EVs run better. The general weight of the vehicle is reduced by these custom-shaped profiles, which has a direct effect on its range and energy efficiency. To meet stricter environmental rules and customer requests for longer-range electric vehicles, German EV manufacturers know how important it is to use these lightweight solutions.

Versatility in Design and Application

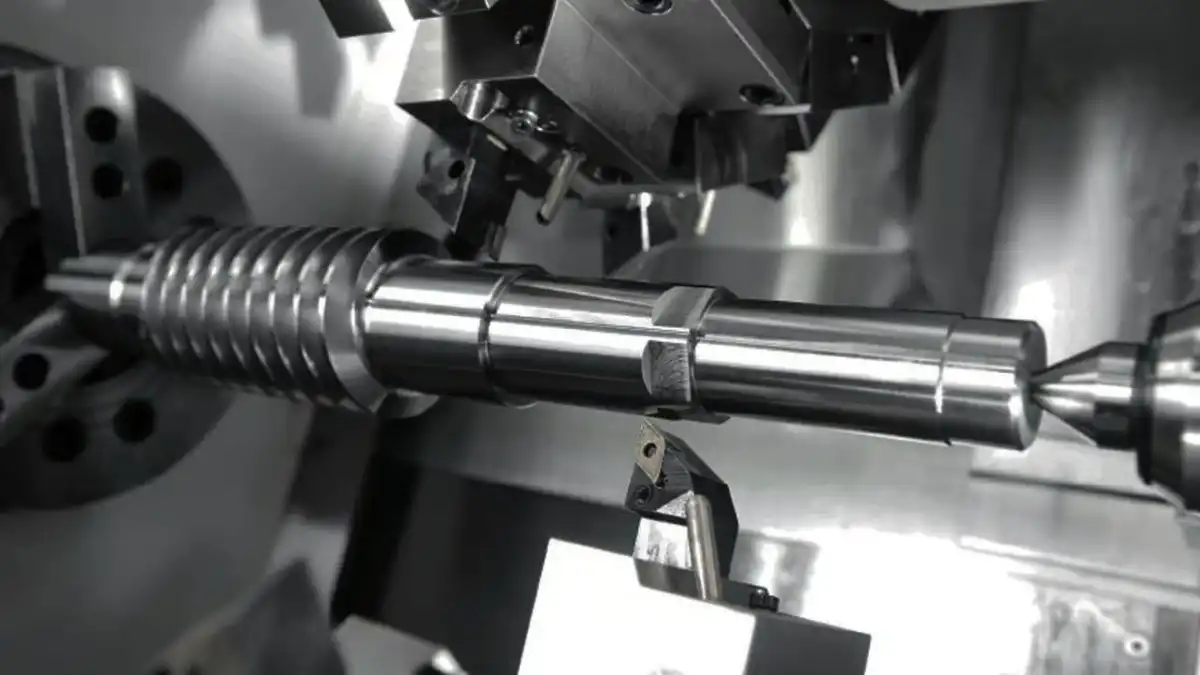

Aluminum extrusions' flexibility enables the creation of intricate profiles that meet the needs of electric vehicles. Customization is possible with aluminum extrusions, which can be used to make anything from battery enclosures to structural parts. This gives German EV companies the freedom to come up with new ideas and make styles that make their cars stand out in a crowded market. For the precise automotive business, aluminum extrusions are the best way to make complex shapes with very tight tolerances.

Thermal Management Benefits

EV design needs to be able to handle heat well, especially when it comes to battery systems. Because they are so good at getting rid of heat, aluminum extrusions are great for making cooling channels and heat sinks. By getting these parts from China, German EV makers can get access to more advanced thermal management systems that help keep battery temperatures at the right level, extend battery life, and improve vehicle performance overall. As EVs keep getting better with bigger packs and faster charging, this part becomes even more important.

Advantages of Sourcing Aluminum Extrusions from China

Cost-Effective Production at Scale

Germany's electric vehicle companies are looking to China for aluminum extrusions because of how cheap it is to make a lot of them. Chinese makers have put a lot of money into modern extrusion facilities that let them make a lot of high-quality parts at low costs. EV makers need this cost edge if they want to make their cars more affordable and available to more people. German electric vehicle (EV) businesses can make more money and put more into research and development by lowering production costs without lowering quality.

Advanced Manufacturing Capabilities

China's aluminum extrusion business has come a long way in the last few years, using cutting-edge tools and technologies. A lot of Chinese providers can now do high-tech manufacturing, like precise CNC machining, surface treatments, and extrusions of complex profiles. With these skills, German EV companies can find very specific parts that meet their strict requirements. Using both old and new methods of manufacturing together with traditional extrusion makes sure that the end products are of the highest quality and can be used in the tough automotive industry.

Robust Supply Chain and Logistics

China's well-developed transportation and supply chain infrastructure is another strong reason for German electric vehicle (EV) makers to buy aluminum extrusions from the country. Getting raw materials, streamlining production, and making sure deliveries happen quickly and reliably are all made possible by the linked supply chain. Chinese suppliers can offer shorter lead times and more flexible production schedules because of this strong ecosystem. This is very important in the fast-paced EV business. A lot of Chinese manufacturers have also worked with clients from other countries before, which makes contact easy and makes sure they follow global quality standards.

Overcoming Challenges in Cross-Border Sourcing

Ensuring Quality Control and Compliance

There are many good reasons to buy aluminum extrusions from China, but German electric vehicle companies need to make sure they follow international norms and quality control. Many Chinese suppliers have taken steps to deal with this problem by getting ISO certifications and setting up strict quality control systems. To lower their risks even more, German companies can do regular checks, make clear quality agreements, and work closely with their Chinese partners to make sure all requirements are met. EV makers can keep the high standards for their products by working with respected suppliers who have a history of working with the car industry.

Navigating Cultural and Communication Differences

To do cross-border buying right, you need to be able to communicate clearly. German electric vehicle (EV) companies can get around language and cultural hurdles by working with Chinese suppliers who have worked with clients from other countries before. Many Chinese manufacturers now have employees who can speak more than one language and use high-tech tools for conversation to make interactions smooth. Setting clear lines of communication, being clear about what is expected, and building long-term relationships can help German companies deal with these problems and make good partnerships with their Chinese providers.

Managing Intellectual Property Concerns

When purchasing from other countries, protecting intellectual property (IP) is a usual concern. China has, however, made a lot of work in making its IP laws and enforcement systems stronger. German electric vehicle (EV) companies can protect their new ideas by carefully choosing partners they can trust, making sure they have strong contracts, and keeping private information separate. Many Chinese suppliers now know how important it is to protect intellectual property (IP) and are ready to work with their clients to keep secret and protect their clients' designs and technologies.

Conclusion

Buying aluminum extrusions from China is a great way for German electric vehicle companies to become more competitive on the world market. China is a good place to get high-quality aluminum parts because it is cheap, has improved manufacturing skills, and has a strong supply chain. German EV makers can use these benefits to drive innovation, cut costs, and speed up their growth in the electric vehicle industry by carefully navigating possible problems and building strong relationships with dependable Chinese suppliers. Strategically finding important parts like aluminum extrusions will be very important in shaping the future of sustainable transportation as the EV market continues to change.

FAQs

Is the quality of aluminum extrusions made in China about the same as that made in Germany?

In fact, a lot of Chinese companies make aluminum extrusions that are of high quality and meet foreign standards. It is important to pick sellers with good reputations and the right certifications.

What can German EV companies do to make sure the quality stays the same when they buy from China?

German businesses can make sure quality is always the same by putting in place strict quality control measures, doing regular audits, and staying in close contact with their providers.

What are the best things about getting aluminum extrusions from China to make EVs?

Cost-effectiveness, advanced manufacturing skills, and access to a strong supply chain are the main perks, and they can all help make EV production more competitive.

Expert Aluminum Extrusion Solutions for EV Manufacturers | BOEN

BOEN is an expert at making high-quality aluminum extrusion products that fit the specific needs of companies that make electric vehicles. Our modern buildings and skilled workers make sure that every project is done correctly, reliably, and at a low cost. We offer complete solutions that meet the strict needs of the car industry, from designing complicated profiles to making rapid prototypes and full-scale production. Work with BOEN to get new aluminum extrusions that will help your EV projects move forward. Email us at contact@boenrapid.com to talk about your needs and find out how we can help you succeed in the market for electric vehicles.

References

"The Role of Aluminum in Electric Vehicles" - Journal of Automotive Engineering, 2022

"Global Supply Chain Trends in the EV Industry" - McKinsey & Company Report, 2023

"Advancements in Aluminum Extrusion Technology for Automotive Applications" - SAE International Paper, 2021

"China's Evolving Role in the Global Automotive Supply Chain" - Boston Consulting Group Analysis, 2023

"Quality Management Systems in Cross-Border Manufacturing" - International Journal of Production Economics, 2022

"Intellectual Property Protection Strategies for Global Sourcing" - Harvard Business Review, 2023

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.