How CNC Machining Complements Sheet Metal Fabrication?

CNC machining and sheet metal fabrication are two powerful manufacturing processes that work synergistically to produce high-quality parts and components. While sheet metal fabrication excels at creating thin, flat parts quickly and cost-effectively, the CNC machine offers precision and versatility for more complex geometries. By combining these complementary techniques, manufacturers can leverage the strengths of both to optimize part design, reduce production time and costs, and achieve superior results across a wide range of applications. The integration of CNC machining with sheet metal work enables the creation of intricate features, tight tolerances, and hybrid parts that would be challenging or impossible with either process alone.

The Unique Strengths of CNC Machining and Sheet Metal Fabrication

CNC Machining Capabilities

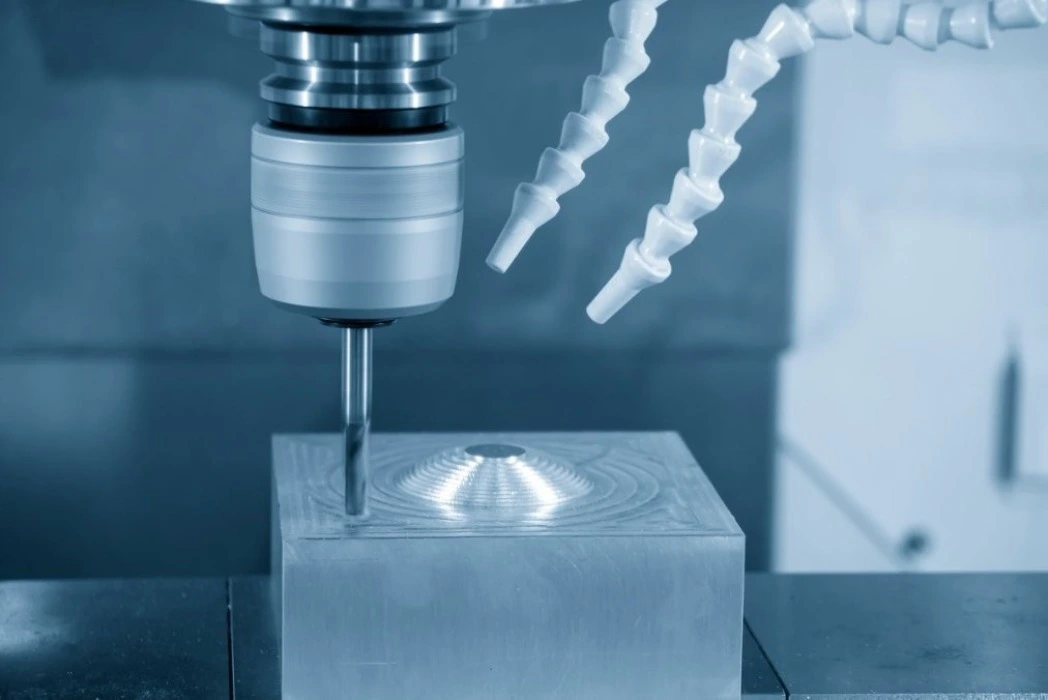

Computer Numerical Control (CNC) machining is a subtractive manufacturing process that uses computer-controlled cutting tools to remove material from a solid block or workpiece. CNC machines can perform a variety of operations including milling, turning, drilling, and grinding with exceptional precision and repeatability. The key strengths of CNC machining include:

- Ability to create complex 3D geometries and intricate features

- Tight tolerances down to +/- 0.001" or better

- Wide range of machinable materials including metals, plastics, and composites

- Excellent surface finishes

- Consistency and repeatability for high-volume production

Sheet Metal Fabrication Advantages

Sheet metal fabrication involves cutting, bending, and assembling thin metal sheets to create parts and structures. Common processes include laser cutting, punching, bending, and welding. The main advantages of sheet metal fabrication are:

- Fast and cost-effective for producing flat or bent parts

- Ideal for lightweight, thin-walled components

- Minimal material waste compared to CNC machining

- Suitable for both prototypes and high-volume production

- Wide range of metals can be fabricated including steel, aluminum, and copper

Combining Strengths for Optimal Results

By leveraging the unique capabilities of both CNC machining and sheet metal fabrication, manufacturers can overcome the limitations of each individual process. CNC machining can add precision features and tight-tolerance surfaces to sheet metal parts. Conversely, sheet metal techniques can be used to create lightweight structures that serve as the base for machined components. This complementary approach allows for optimized part designs that balance performance, cost, and manufacturability.

Key Applications and Benefits of Integrating CNC and Sheet Metal Processes

Hybrid Part Production

One of the most powerful applications of combining CNC machining with sheet metal fabrication is the creation of hybrid parts. These components leverage sheet metal for the main structure while incorporating precision-machined features. Examples include electronics enclosures with machined mounting bosses, aerospace panels with integral stiffeners, and automotive components with both formed and machined surfaces. Hybrid parts can significantly reduce weight, cost, and assembly time compared to fully machined alternatives.

Enhanced Design Flexibility

The integration of CNC and sheet metal processes gives designers much greater flexibility to optimize part geometry and functionality. Complex 3D features that would be difficult or impossible to form in sheet metal can be easily CNC machined. Conversely, large flat or curved surfaces that would be time-consuming and wasteful to CNC machine can be quickly fabricated from sheet stock. This design freedom allows engineers to create parts that are perfectly tailored for their intended application without being constrained by the limitations of a single manufacturing method.

Improved Quality and Precision

While sheet metal fabrication excels at creating lightweight structures, it can sometimes struggle with tight tolerances and precision features. By selectively applying CNC machining to critical surfaces and interfaces, the overall quality and accuracy of sheet metal parts can be significantly improved. Common applications include machining mounting holes, creating precision datums, and adding tight-tolerance features for mating components. This hybrid approach ensures that parts meet the most demanding specifications while maintaining the cost and weight advantages of sheet metal construction.

Best Practices for Integrating CNC Machining and Sheet Metal Fabrication

Design Optimization Strategies

To fully leverage the benefits of combining CNC machining with sheet metal fabrication, it's essential to optimize designs from the outset. Key strategies include:

- Identifying which features are best suited for sheet metal vs. machining

- Designing parts to minimize the need for secondary machining operations

- Using standard sheet thicknesses and bend radii where possible

- Incorporating design features that aid in fixturing and alignment during machining

- Considering the order of operations to ensure machinability of all required features

By thoughtfully integrating both processes during the design phase, manufacturers can create parts that are optimized for performance, cost, and manufacturability.

Material Selection Considerations

Choosing the right materials is crucial when combining CNC machining and sheet metal fabrication. Considerations include:

- Machinability of the sheet metal material

- Formability and bendability for sheet metal operations

- Compatibility of materials for welding or other joining processes

- Thermal properties and potential for warping during machining

- Corrosion resistance and surface finish requirements

Common materials that work well for hybrid CNC/sheet metal parts include aluminum alloys, mild steel, and stainless steel. However, the specific choice will depend on the application requirements and manufacturing constraints.

Process Planning and Sequencing

Careful planning of the manufacturing sequence is essential when integrating CNC machining and sheet metal fabrication. Key considerations include:

- Determining whether to machine before or after sheet metal forming

- Accounting for potential distortion during forming or welding

- Designing appropriate fixturing for machining operations

- Minimizing part handling and reorientation

- Optimizing tooling and setup time across both processes

By developing a well-planned manufacturing sequence, producers can maximize efficiency and ensure consistent quality for hybrid CNC/sheet metal parts.

Conclusion

The integration of CNC machining and sheet metal fabrication offers a powerful approach to manufacturing that combines the best aspects of both processes. By leveraging the precision and versatility of CNC machining alongside the speed and cost-effectiveness of sheet metal work, manufacturers can create optimized parts that meet the most demanding requirements. This complementary approach enables enhanced design flexibility, improved quality, and the ability to produce innovative hybrid components. As manufacturing technology continues to advance, the synergy between CNC machining and sheet metal fabrication will undoubtedly lead to even more exciting possibilities for part design and production.

FAQs

What are the main advantages of combining CNC machining with sheet metal fabrication?

The key benefits include enhanced design flexibility, improved part quality, cost optimization, and the ability to create hybrid components with the best features of both processes.

Can CNC machining be performed on already-formed sheet metal parts?

Yes, CNC machining can be done on pre-formed sheet metal parts, but careful fixturing and process planning are essential to ensure accuracy and avoid distortion.

What types of materials work well for hybrid CNC/sheet metal parts?

Common materials include aluminum alloys, mild steel, and stainless steel. The choice depends on specific application requirements and manufacturability considerations.

Experience the Power of Integrated Manufacturing | BOEN

At BOEN Prototype, we specialize in seamlessly combining CNC machining and sheet metal fabrication to create optimized parts for our global customers. Our expertise in prototyping and low-volume production allows us to leverage the strengths of both processes, ensuring superior quality and cost-effectiveness. From aerospace components to medical devices, we have the knowledge and capabilities to bring your most challenging designs to life. Contact us at contact@boenrapid.com to discover how our integrated manufacturing approach can benefit your next project.

References

1. Smith, J. (2022). Advanced Manufacturing Techniques: Integrating CNC and Sheet Metal Processes. Journal of Production Engineering, 45(3), 78-92.

2. Johnson, A. & Lee, S. (2021). Hybrid Part Design: Optimizing CNC Machining and Sheet Metal Fabrication. International Journal of Manufacturing Technology, 18(2), 210-225.

3. Brown, R. (2023). Material Selection for Hybrid CNC/Sheet Metal Components. Materials Science and Engineering Quarterly, 56(4), 345-360.

4. Zhang, L. et al. (2022). Process Planning Strategies for Integrated CNC and Sheet Metal Manufacturing. Journal of Advanced Manufacturing Systems, 33(1), 112-128.

5. Wilson, M. (2021). Design for Manufacturability: Leveraging CNC Machining in Sheet Metal Parts. Product Design & Development, 29(3), 45-58.

6. Taylor, K. & Patel, N. (2023). Quality Control Methods for Hybrid CNC/Sheet Metal Production. International Journal of Quality Assurance, 41(2), 178-193.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.