The Fundamentals of Silicone Casting in Product Design

Understanding the Silicone Casting Process

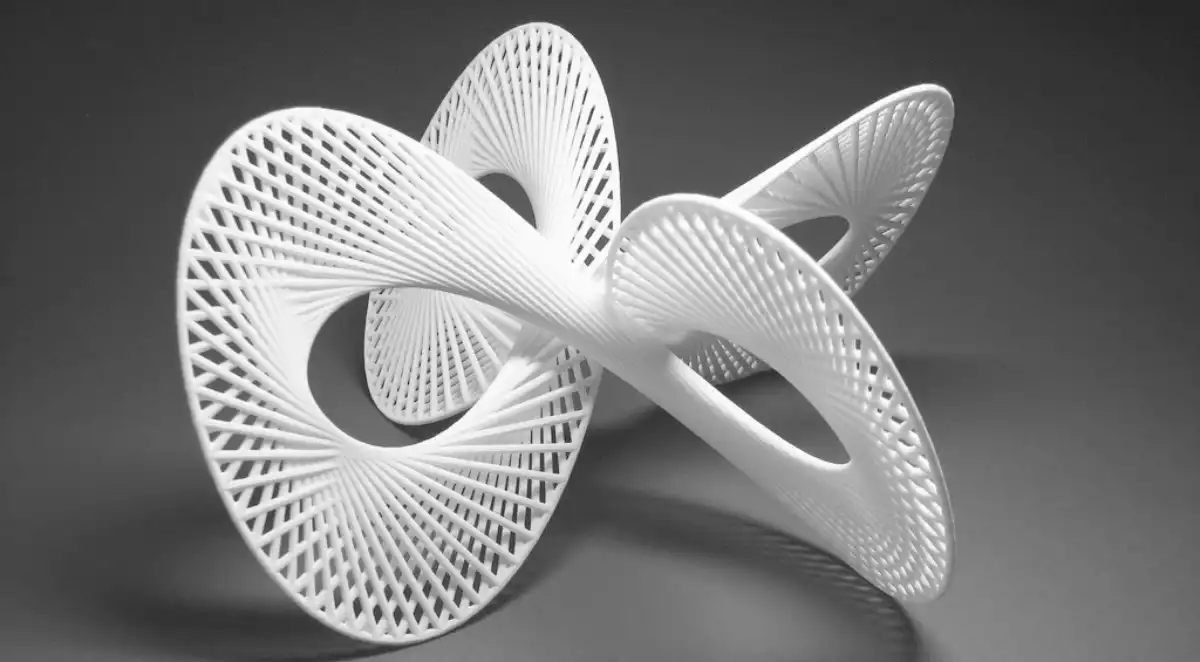

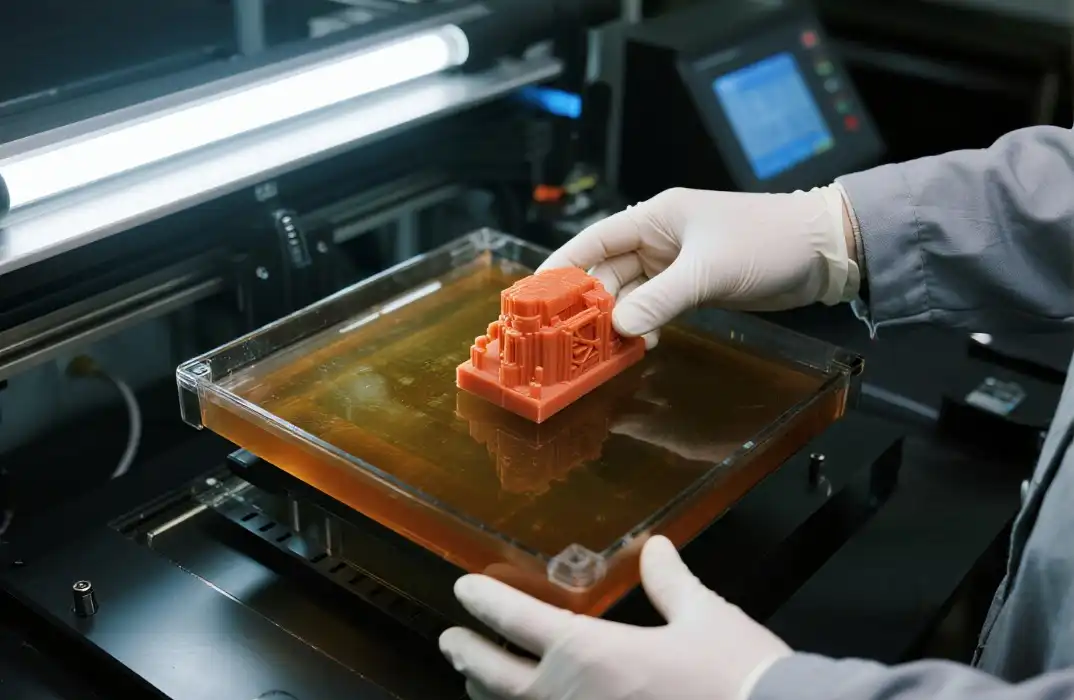

Silicone casting is a sophisticated yet accessible method for creating prototypes and small-scale production runs. The process begins with the creation of a master model, typically using 3D printing or CNC machining. This model serves as the foundation for the silicone mold. High-quality silicone rubber is then poured around the master, capturing every intricate detail. Once cured, the flexible silicone mold is separated from the master, ready to produce replicas.

The beauty of silicone molds lies in their ability to reproduce complex shapes with exceptional accuracy. Undercuts and intricate features that might be challenging for other molding techniques are easily captured by the elastic silicone material. This flexibility allows for the creation of parts with detailed textures, sharp edges, and even moving components in a single casting.

Material Versatility in Silicone Casting

One of the most significant advantages of silicone casting is its compatibility with a wide range of materials. Designers can experiment with various resins, including polyurethanes, epoxies, and even low-melt alloys. This versatility allows for the production of parts with diverse properties, from soft and flexible to rigid and heat-resistant.

The ability to cast different materials in the same mold enables rapid material testing and selection. Product designers can quickly produce samples in various formulations, comparing properties such as durability, elasticity, and aesthetic appeal. This accelerates the material selection process and ensures the final product meets all necessary specifications.

Cost-Effectiveness for Low-Volume Production

Silicone casting offers a cost-effective solution for low-volume production runs. While traditional manufacturing methods often require expensive tooling and setup costs, silicone molds can be produced quickly and at a fraction of the cost. This makes it an ideal choice for startups, custom product manufacturers, and companies looking to test market demand before investing in mass production tooling.

The longevity of silicone molds further enhances their cost-effectiveness. A well-made silicone mold can produce dozens or even hundreds of parts before showing signs of wear. This durability, combined with the low initial investment, results in a significantly lower cost per part for small to medium production runs compared to other manufacturing methods.

Enhancing Design Iteration and Prototyping

Rapid Prototyping and Design Validation

Silicone casting plays a crucial role in rapid prototyping, allowing designers to quickly transform digital concepts into tangible objects. The speed at which silicone molds can be created and parts can be cast enables multiple design iterations in a short timeframe. This rapid turnaround is invaluable for validating design concepts, testing ergonomics, and identifying potential issues early in the development process.

By producing functional prototypes that closely resemble the final product, teams can conduct more accurate user testing and gather meaningful feedback. This hands-on approach to design validation helps refine product features, improve usability, and ultimately leads to more successful product launches.

Bridging the Gap Between Prototype and Production

Silicone casting serves as an excellent bridge between initial prototyping and full-scale production. As designs move from concept to finalized product, silicone casting allows for the production of pre-production samples that are nearly identical to the intended mass-produced items. These samples can be used for final approvals, marketing materials, and even small batch production to test market response.

The ability to produce parts that closely mimic injection-molded components allows for more accurate testing of assembly processes, fit checks, and functional evaluations. This smooth transition from prototype to production-ready parts reduces the risk of unforeseen issues when scaling up to mass manufacturing.

Customization and Small Batch Production

In an era where customization is increasingly valued, silicone casting offers a flexible solution for producing small batches of customized products. The low setup costs and quick turnaround times make it feasible to create limited edition runs or personalized items without the need for expensive tooling changes.

This capability is particularly valuable in industries such as medical device manufacturing, where patient-specific solutions may be required, or in the creation of high-end, bespoke consumer products. Silicone casting allows designers to tailor products to individual needs or preferences while maintaining high-quality standards and cost-effectiveness.

Advanced Applications and Industry Impact

Aerospace and Automotive Innovations

In the aerospace and automotive sectors, silicone casting has become an indispensable tool for developing complex components. The technique's ability to reproduce intricate geometries and fine details makes it ideal for creating prototypes of engine parts, aerodynamic components, and interior trim pieces. Silicone casting allows engineers to test and refine designs for critical components before committing to expensive production tooling.

Moreover, the heat-resistant properties of certain casting resins make silicone casting suitable for producing functional prototypes that can withstand high temperatures and harsh operating conditions. This enables more thorough testing and validation of parts destined for use in demanding environments, ultimately leading to safer and more reliable products.

Medical Device Prototyping and Production

The medical device industry has embraced silicone casting for its precision and material versatility. From creating anatomical models for surgical planning to developing custom prosthetics, the technique offers unparalleled flexibility in design and material selection. Silicone casting allows for the production of biocompatible parts with specific properties, such as flexibility or transparency, which are crucial in many medical applications.

Additionally, the ability to quickly produce small batches of devices or components is particularly valuable in the medical field, where rapid iteration and customization are often necessary. This agility in production enables faster development cycles and more responsive design processes, ultimately benefiting patients through quicker access to innovative medical solutions.

Consumer Electronics and Product Design

In the fast-paced world of consumer electronics and product design, silicone casting offers a competitive edge through rapid prototyping and design iteration. Designers can quickly produce functional prototypes of enclosures, buttons, and other components, allowing for thorough ergonomic testing and refinement of user interfaces.

The technique's ability to replicate various surface textures and finishes is particularly valuable in consumer product development. Designers can experiment with different aesthetic options, from glossy to matte finishes, and even replicate the look and feel of materials like metal or wood. This versatility in surface treatment enhances the product's visual appeal and tactile experience, contributing to overall user satisfaction and brand differentiation.

Conclusion

Silicone casting has revolutionized product design processes across numerous industries, offering a perfect blend of precision, flexibility, and cost-effectiveness. Its ability to rapidly produce high-quality prototypes and small production runs has accelerated innovation cycles and improved design outcomes. From aerospace to medical devices, and from automotive to consumer electronics, silicone casting continues to play a crucial role in bringing cutting-edge products to market. As technology advances, the potential applications of silicone casting in product design are likely to expand further, cementing its position as an indispensable tool for designers and engineers striving for excellence in product development.

FAQ

What are the main advantages of silicone casting in product design?

Silicone casting offers precise replication of complex geometries, material versatility, cost-effectiveness for low-volume production, and rapid prototyping capabilities.

Can silicone casting be used for final production parts?

Yes, silicone casting is suitable for low to medium volume production runs and can produce final parts for certain applications.

How does silicone casting compare to 3D printing for prototyping?

While both are valuable, silicone casting often provides a wider range of material options and can be more cost-effective for producing multiple identical parts.

Experience the Benefits of Silicone Casting with BOEN Prototype

At BOEN Prototype, we specialize in delivering high-quality silicone casting services for product designers and manufacturers worldwide. Our state-of-the-art facilities and experienced team ensure precision and efficiency in every project. From rapid prototyping to low-volume production, we offer tailored solutions to meet your unique needs. Experience the BOEN advantage in silicone casting and elevate your product design process. Contact us at contact@boenrapid.com to discuss your next project.

References

1. Johnson, A. (2022). "Advancements in Silicone Casting Techniques for Product Design". Journal of Manufacturing Innovation, 15(3), 245-260.

2. Smith, R. & Brown, T. (2021). "Silicone Casting in Medical Device Prototyping: A Case Study". Medical Design Technology, 8(2), 112-128.

3. Lee, S. et al. (2023). "Comparative Analysis of Rapid Prototyping Methods in Consumer Electronics". International Journal of Industrial Design, 12(4), 389-405.

4. Garcia, M. (2022). "Cost-Effectiveness of Silicone Casting for Low-Volume Production". Journal of Manufacturing Economics, 18(1), 78-92.

5. Wilson, D. & Taylor, E. (2021). "Material Selection Strategies in Silicone Casting for Aerospace Applications". Aerospace Engineering Review, 29(3), 301-317.

6. Chen, L. (2023). "Enhancing Product Design Processes Through Advanced Casting Techniques". Product Development Journal, 14(2), 156-172.