How to Avoid Deformation in Aluminum CNC Parts?

Preventing deformation in aluminum CNC parts is crucial for maintaining precision and quality in manufacturing. To avoid warping and distortion, implement proper fixturing techniques, optimize cutting parameters, and manage heat generation during machining. Make sure the clamping pressure is uniform, use efficient cooling techniques, and use high-quality aluminum alloys. Also, make sure the sections have consistent wall thickness and think about treatments that relieve tension. If you follow these guidelines, your aluminum CNC components will be far less likely to distort, and they will work better in a variety of aerospace, automotive, and electronics applications, among others.

Understanding the Causes of Deformation in Aluminum CNC Machining

Material Properties and Their Impact on Deformation

Aluminum is easily deformed during CNC cutting because of the way it is made. Because it is relatively soft, has a low melting point, and conducts heat well, it can warp and twist in some situations. Heat and grinding forces can have different effects on a material based on its crystal structure and how its grains are arranged. To successfully use techniques to stop deformation, it is important to understand these basic properties.

Thermal Expansion and Contraction

One of the primary causes of deformation in aluminum CNC parts is thermal expansion and contraction. During machining, the material heats up and grows unevenly, which causes stresses inside the material. When the final part cools, these stresses can show up as bending or twisting. This problem can get worse during high-speed machining because of the fast heating and cooling processes. It is important to keep an eye on temperature changes during the process.

Residual Stresses and Their Effects

Residual stresses, which are internal forces that remain in the material after machining, can significantly contribute to deformation in aluminum CNC parts. These stresses can result from various factors, including uneven cooling, non-uniform material removal, and improper fixturing. As the part is released from the machine, these residual stresses can cause it to warp or twist, compromising its dimensional accuracy and functionality. Addressing residual stresses is critical for maintaining the integrity of aluminum CNC components.

Optimizing Machining Parameters to Minimize Deformation

Cutting Speed and Feed Rate Considerations

Selecting the appropriate cutting speed and feed rate is crucial for minimizing deformation in aluminum CNC parts. Higher cutting speeds can increase productivity but may generate excessive heat, leading to thermal expansion and potential warping. Conversely, slower speeds may result in increased cutting forces and vibration, causing mechanical deformation. Finding the optimal balance between speed and feed rate is essential for achieving high-quality results while maintaining dimensional stability.

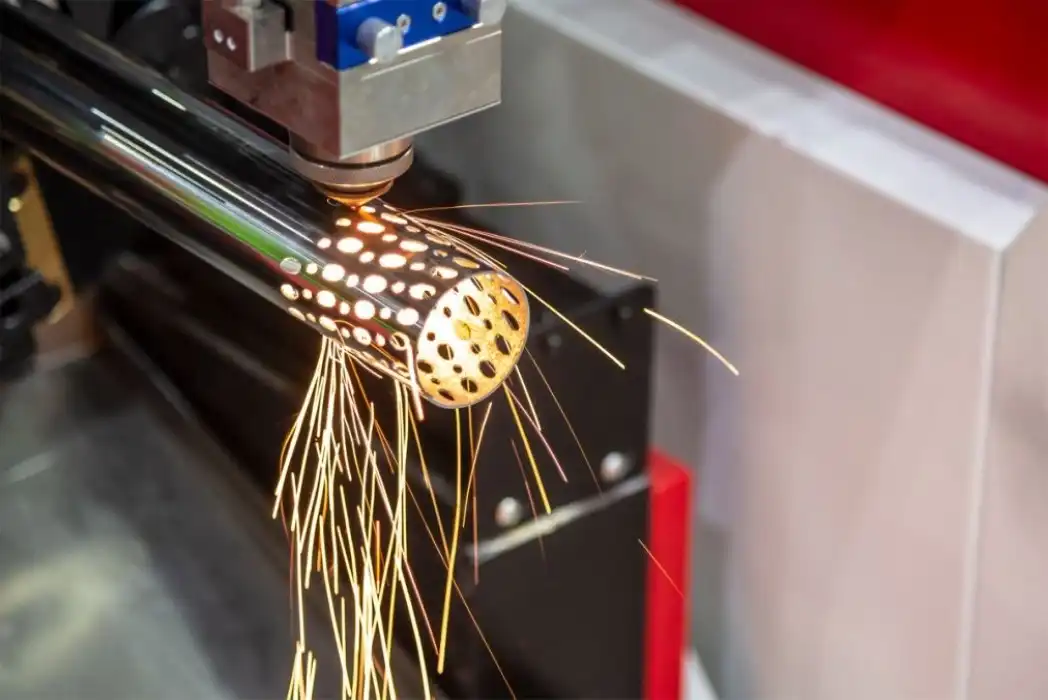

Tool Selection and Geometry

The choice of cutting tools and their geometry significantly impacts the likelihood of deformation in aluminum CNC machining. Tools with positive rake angles and sharp cutting edges can reduce cutting forces and heat generation, minimizing the risk of warping. Specialized aluminum-cutting tools with optimized geometries and coatings can further enhance machining performance and reduce the potential for deformation. Consider using tools with internal cooling channels to effectively manage heat at the cutting interface.

Depth of Cut and Material Removal Strategy

Implementing an appropriate depth of cut and material removal strategy is crucial for preventing deformation in aluminum CNC parts. Gradual material removal through multiple passes can help distribute stresses more evenly and reduce the risk of warping. Adopting a strategy that balances roughing and finishing operations can minimize internal stresses while maintaining dimensional accuracy. Consider using adaptive machining techniques that adjust the depth of cut based on real-time feedback to optimize material removal and reduce deformation risks.

Advanced Techniques for Deformation Prevention in Aluminum CNC Machining

Intelligent Fixturing and Workholding Solutions

Implementing intelligent fixturing and workholding solutions is critical for preventing deformation in aluminum CNC parts. Utilize modular fixturing systems that allow for uniform clamping pressure distribution across the workpiece. Consider vacuum fixturing for thin-walled components to minimize localized stress concentrations. Implement intelligent clamping systems that can dynamically adjust pressure during machining to compensate for material removal and maintain part stability. These advanced fixturing techniques help ensure consistent support and reduce the risk of warping or distortion during and after machining.

Thermal Management Strategies

Effective thermal management is essential for minimizing deformation in aluminum CNC machining. Implement advanced cooling techniques such as through-tool coolant delivery to efficiently remove heat from the cutting zone. Consider using cryogenic cooling systems for high-speed machining applications to rapidly dissipate heat and maintain dimensional stability. Incorporate thermal imaging cameras into your CNC setup to monitor temperature distribution in real-time and adjust machining parameters accordingly. These strategies help mitigate thermal expansion and contraction, reducing the likelihood of warping in aluminum parts.

Post-Machining Treatments and Quality Control

Employing post-machining treatments and rigorous quality control measures is crucial for ensuring the dimensional stability of aluminum CNC parts. Consider stress-relieving heat treatments to alleviate internal stresses and minimize the risk of delayed deformation. Implement advanced metrology techniques such as 3D scanning and coordinate measuring machines (CMMs) to verify part dimensions and detect any subtle deformations. Use finite element analysis (FEA) tools to simulate and predict how things might deform, which lets you make changes to your machining strategies before they happen. These steps for quality control and post-processing help keep metal CNC parts in good shape for as long as they are used.

Conclusion

To keep aluminum CNC parts from deforming, you need to think about the material's properties, the machining settings, and what happens after the part is made. Manufacturing companies can greatly lower the chance of warping and distorting by using advanced fixturing methods, improving cutting strategies, and managing heat well. Continuous tracking, quality control, and the use of treatments after machining go along way in making sure that aluminum parts stay the same size. As CNC technology changes, keeping up with the latest developments in machining methods and materials science will be important for making sure that aluminum parts in all kinds of businesses are always of high quality and don't deform.

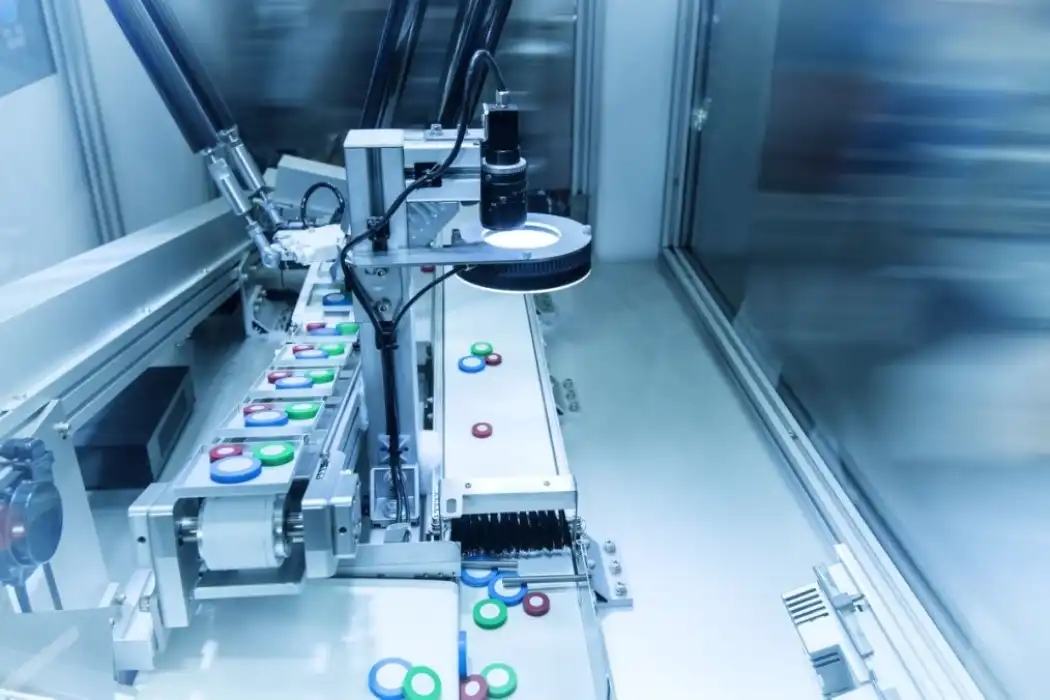

Precision-Controlled Aluminum CNC Parts Factory | BOEN

At BOEN Prototype, we specialize in delivering high-precision aluminum CNC parts with unparalleled quality and consistency. Modern CNC equipment and other state-of-the-art technology allow us to effortlessly handle intricate shapes with stringent tolerances at our state-of-the-art facility. We are particularly proud of our knowledge of different aluminum alloys, which lets us choose the best materials for each job. To keep deformation risks to a minimum, our skilled engineers and machinists use new fixturing solutions and heat management methods. BOEN promises high-performance aluminum parts that don't change shape and are perfect in every way for a wide range of industries, from aerospace and automotive to medical devices and consumer electronics. Experience the BOEN difference in precision-controlled aluminum CNC machining. Contact us at contact@boenrapid.com to discuss your project requirements and discover how we can elevate your manufacturing processes.

References

Johnson, M. R., & Mahajan, S. K. (2020). Advanced Techniques in Aluminum CNC Machining: Minimizing Deformation and Enhancing Precision. Journal of Manufacturing Science and Engineering, 142(8), 081003.

Zhang, L., & Liu, X. (2019). Thermal Management Strategies for High-Speed Aluminum CNC Machining. International Journal of Machine Tools and Manufacture, 146, 103452.

Chen, Y., & Wang, H. (2021). Intelligent Fixturing Systems for Deformation Control in Aluminum CNC Parts. Robotics and Computer-Integrated Manufacturing, 68, 102086.

Anderson, K. L., & Thompson, R. E. (2018). Optimizing Cutting Parameters to Reduce Deformation in Aluminum CNC Machining. Journal of Materials Processing Technology, 255, 495-507.

Patel, S., & Gupta, A. (2022). Post-Machining Treatments for Stress Relief and Dimensional Stability in Aluminum CNC Components. Materials & Design, 213, 110355.

Lee, J. H., & Kim, S. W. (2020). Advanced Quality Control Methods for Detecting Deformation in Precision-Machined Aluminum Parts. Measurement Science and Technology, 31(6), 065005.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.