Planning and Design Considerations for Mechanical Part Prototypes

Defining Prototype Objectives and Requirements

Before diving into the prototyping process, it's essential to clearly define your objectives and requirements. This initial step sets the foundation for your entire prototyping journey. Start by identifying the specific purpose of your prototype - whether it's for concept validation, functional testing, or presentation to stakeholders. Consider the following aspects:

- Functionality: Determine which features and functions the prototype needs to demonstrate.

- Accuracy: Decide on the level of precision required for your prototype.

- Material properties: Consider the physical characteristics needed to represent the final product.

- Timeline: Establish a realistic schedule for prototype development and testing.

- Budget: Set a budget that aligns with your project goals and constraints.

By clearly outlining these factors, you'll be better equipped to make informed decisions throughout the prototyping process, ensuring that your efforts are focused and efficient.

Selecting the Right Prototyping Method

Choosing the appropriate prototyping method is crucial for creating effective mechanical part prototypes. Different techniques offer varying levels of accuracy, speed, and cost-effectiveness. Consider these popular methods:

- 3D Printing: Ideal for complex geometries and rapid iteration.

- CNC Machining: Offers high precision and a wide range of material options.

- Injection Molding: Suitable for prototypes that closely resemble final production parts.

- Sheet Metal Fabrication: Effective for creating prototypes of enclosures and structural components.

Each method has its strengths and limitations, so carefully evaluate your project requirements to select the most suitable approach. In some cases, a combination of techniques may be necessary to achieve the desired results.

Optimizing Design for Prototyping

To ensure the success of your mechanical part prototypes, it's crucial to optimize your designs for the chosen prototyping method. This involves considering the following aspects:

- Design for Manufacturability (DFM): Adapt your design to suit the limitations and capabilities of the prototyping process.

- Simplification: Streamline complex features where possible to reduce production time and costs.

- Modular design: Consider breaking down complex assemblies into smaller, more manageable components.

- Tolerance analysis: Account for manufacturing tolerances to ensure proper fit and function.

By optimizing your design for prototyping, you can minimize potential issues during production and improve the overall quality of your mechanical part prototypes.

Material Selection and Manufacturing Techniques for Mechanical Prototypes

Choosing the Right Materials for Your Prototype

Selecting the appropriate materials for your mechanical part prototypes is crucial for achieving accurate results and meaningful testing. Consider the following factors when making your selection:

- Physical properties: Choose materials that closely match the strength, flexibility, and thermal characteristics of the final product.

- Manufacturability: Ensure the selected materials are compatible with your chosen prototyping method.

- Cost-effectiveness: Balance material costs with the required performance and accuracy of your prototype.

- Availability: Consider lead times and sourcing options for your chosen materials.

Popular materials for mechanical part prototypes include various plastics (e.g., ABS, PLA, Nylon), metals (e.g., aluminum, steel, titanium), and composites. Each material offers unique properties and advantages, so carefully evaluate your options based on your specific project requirements.

Advanced Manufacturing Techniques for Precision Prototyping

To create highly accurate and functional mechanical part prototypes, consider leveraging advanced manufacturing techniques. These methods offer improved precision, faster turnaround times, and enhanced capabilities compared to traditional approaches:

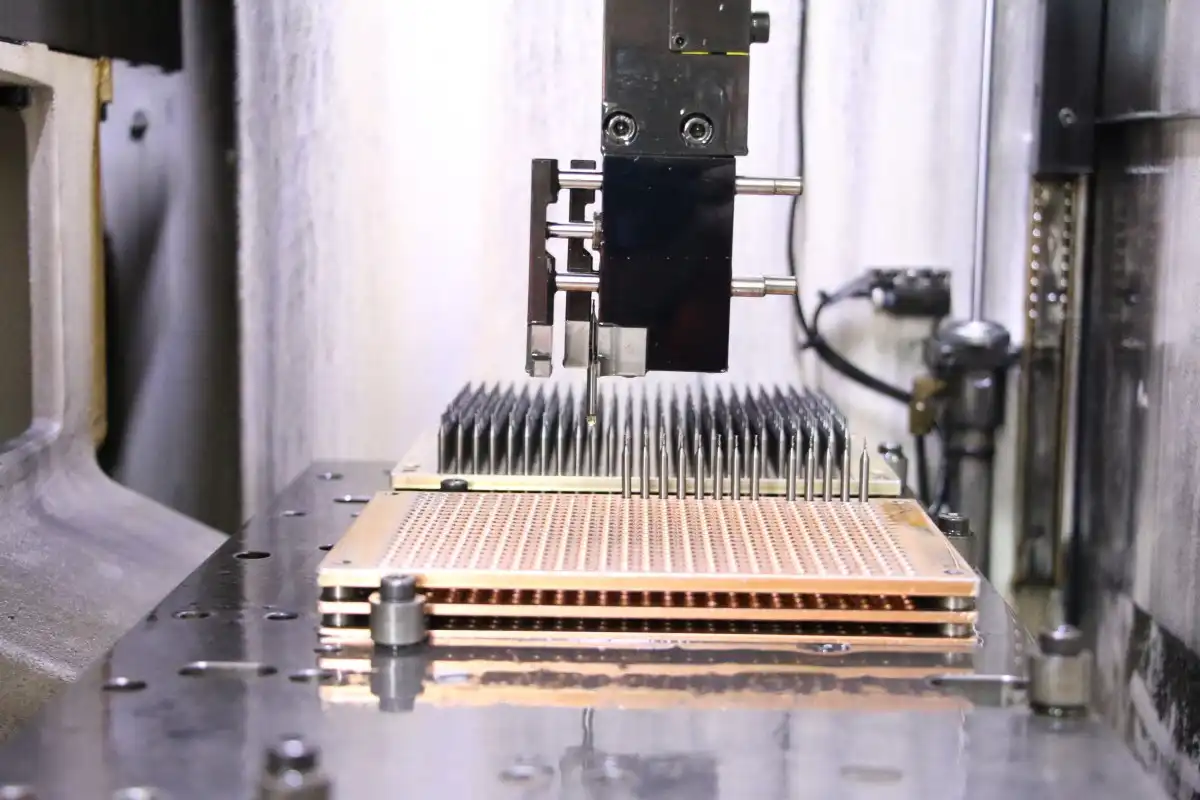

- Multi-axis CNC machining: Enables complex geometries and high-precision parts.

- Selective Laser Sintering (SLS): Ideal for creating strong, durable prototypes with complex internal structures.

- Metal 3D printing: Allows for the creation of intricate metal parts with unique geometries.

- Hybrid manufacturing: Combines additive and subtractive processes for optimal results.

By utilizing these advanced techniques, you can push the boundaries of what's possible in mechanical part prototyping, creating more accurate and functional prototypes that closely resemble the final product.

Finishing and Post-Processing Techniques

After manufacturing your mechanical part prototypes, various finishing and post-processing techniques can enhance their appearance, functionality, and durability:

- Surface treatments: Improve aesthetics and functionality through processes like painting, anodizing, or plating.

- Heat treatment: Enhance material properties such as strength and hardness.

- Machining and polishing: Refine surfaces and improve dimensional accuracy.

- Assembly and bonding: Join multiple components using appropriate adhesives or mechanical fasteners.

Proper finishing and post-processing can significantly improve the quality and performance of your mechanical part prototypes, ensuring they accurately represent the final product and provide valuable insights during testing and evaluation.

Testing, Iteration, and Validation of Mechanical Part Prototypes

Implementing Effective Testing Protocols

Rigorous testing is essential to validate the performance and functionality of your mechanical part prototypes. Develop a comprehensive testing protocol that addresses the following aspects:

- Functional testing: Verify that the prototype performs its intended functions as designed.

- Stress testing: Subject the prototype to extreme conditions to identify potential failure points.

- Environmental testing: Evaluate the prototype's performance under various environmental conditions.

- Compatibility testing: Ensure the prototype integrates seamlessly with other components or systems.

- User testing: Gather feedback from potential users to assess ergonomics and usability.

By implementing a thorough testing regimen, you can identify and address potential issues early in the development process, saving time and resources in the long run.

Iterative Design and Rapid Prototyping

The process of creating effective mechanical part prototypes often involves multiple iterations. Embrace an iterative approach to refine and improve your designs:

- Rapid prototyping: Utilize quick turnaround manufacturing methods to produce multiple iterations quickly.

- Design revisions: Incorporate feedback and test results into subsequent design iterations.

- Parallel prototyping: Create multiple design variations simultaneously to explore different solutions.

- Virtual prototyping: Use simulation software to test and refine designs before physical prototyping.

By adopting an iterative approach, you can continuously improve your mechanical part prototypes, addressing issues and optimizing performance with each iteration.

Validating Prototype Performance and Manufacturability

Before finalizing your mechanical part prototype, it's crucial to validate both its performance and manufacturability. Consider the following steps:

- Benchmark testing: Compare your prototype's performance against industry standards or competitor products.

- Design for Manufacturing (DFM) review: Assess the prototype's suitability for mass production.

- Cost analysis: Evaluate the production costs and potential optimizations for large-scale manufacturing.

- Quality assurance: Implement quality control measures to ensure consistency across multiple prototypes.

Thorough validation ensures that your mechanical part prototype not only meets performance requirements but is also ready for efficient and cost-effective production at scale.

Conclusion

Creating effective mechanical part prototypes is a critical step in the product development process, requiring careful planning, material selection, and advanced manufacturing techniques. By following the strategies outlined in this guide, you can develop prototypes that accurately represent your final product, enabling thorough testing and validation. Remember to define clear objectives, choose appropriate materials and manufacturing methods, and implement rigorous testing protocols. Embrace an iterative approach to continuously refine and improve your designs, and always validate both performance and manufacturability before moving to full-scale production. With these best practices in mind, you'll be well-equipped to create high-quality mechanical part prototypes that drive successful product development.

FAQs

1. What is the most cost-effective method for creating mechanical part prototypes?

The most cost-effective method depends on your specific requirements, but 3D printing is often a good option for rapid and affordable prototyping of small to medium-sized parts.

2. How long does it typically take to create a mechanical part prototype?

The timeline can vary greatly depending on complexity, but simple prototypes can be produced in a few days, while more complex ones may take several weeks.

3. Can I use the same materials for prototypes as for the final product?

While it's ideal to use similar materials, sometimes alternative materials are used for prototypes to reduce costs or improve manufacturing speed. The key is to choose materials with similar properties.

Expert Mechanical Part Prototype Manufacturing | BOEN

At BOEN Prototype, we specialize in creating high-quality mechanical part prototypes using advanced manufacturing techniques. Our experienced team of engineers and designers can help bring your ideas to life with precision and efficiency. As a leading supplier and manufacturer in the industry, we offer a wide range of prototyping services, including CNC machining, rapid injection molding, and 3D printing. Contact us at contact@boenrapid.com to discuss your prototyping needs and experience our exceptional service firsthand.

References

Smith, J. (2022). "Advanced Techniques in Mechanical Prototyping." Journal of Engineering Design, 35(4), 287-301.

Johnson, A. et al. (2021). "Material Selection for Effective Prototype Development." Materials Today, 18(2), 112-125.

Brown, R. (2023). "Iterative Design Processes in Mechanical Engineering." International Journal of Product Development, 29(3), 401-415.

Lee, S. and Kim, H. (2022). "Optimizing Prototyping Strategies for Mechanical Parts." Rapid Prototyping Journal, 28(1), 78-92.

Thompson, M. (2021). "Testing Protocols for Mechanical Prototypes: Best Practices and Case Studies." Journal of Quality and Reliability Engineering, 37(2), 156-170.

Garcia, E. et al. (2023). "Advancements in 3D Printing Technologies for Mechanical Prototyping." Additive Manufacturing, 42, 201-215.