Key Strategies for Ensuring Prototype Quality

Material Selection and Engineering Precision

Selecting the right materials is paramount in creating high-quality pre-production prototypes. Different materials offer unique properties that can significantly impact the prototype's performance, durability, and overall quality. For instance, when working with plastic prototypes, considerations such as tensile strength, heat resistance, and flexibility come into play. Metal prototypes, on the other hand, may require attention to factors like corrosion resistance, conductivity, and weight.

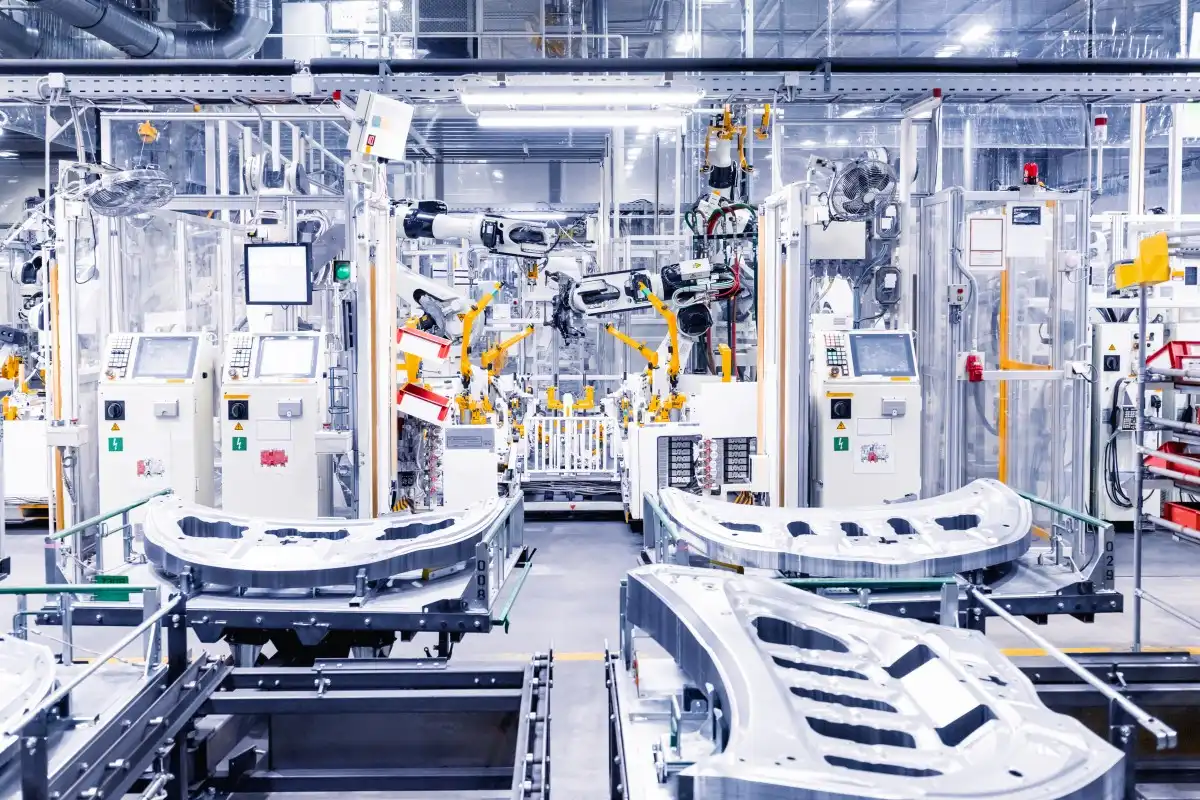

Engineering precision is equally crucial in prototype development. Utilizing advanced manufacturing techniques such as CNC machining, rapid injection molding, and 3D printing allows for tight tolerances and intricate designs. These methods ensure that each component of the prototype is crafted with utmost accuracy, resulting in a faithful representation of the final product.

Moreover, integrating computer-aided design (CAD) and simulation tools in the prototyping process can significantly enhance quality. These technologies enable engineers to optimize designs, predict performance, and identify potential issues before physical production begins, saving time and resources while improving overall prototype quality.

Comprehensive Testing and Quality Control Measures

Implementing robust testing protocols is essential for validating the quality and functionality of pre-production prototypes. A comprehensive testing regimen should encompass various aspects, including performance testing, durability assessments, and environmental simulations. This multi-faceted approach helps identify potential weaknesses or areas for improvement in the prototype design.

Quality control measures should be integrated throughout the prototyping process, from initial concept to final production. This includes regular inspections, dimensional checks, and performance evaluations at each stage of development. By implementing stringent quality control procedures, manufacturers can detect and address issues early, preventing costly mistakes and ensuring consistent quality across all prototypes.

Additionally, employing non-destructive testing methods, such as X-ray inspections or ultrasonic testing, can provide valuable insights into the internal structure and integrity of prototypes without compromising their functionality. These advanced techniques are particularly useful for complex components or assemblies where traditional inspection methods may fall short.

Iterative Design and Continuous Improvement

Adopting an iterative approach to prototype development is key to achieving optimal quality. This process involves creating multiple versions of a prototype, each building upon the lessons learned from its predecessors. By continuously refining and improving the design based on feedback and test results, manufacturers can gradually enhance the prototype's quality and performance.

Incorporating user feedback and real-world testing into the iterative process is crucial. This allows designers and engineers to identify usability issues, ergonomic concerns, or unforeseen challenges that may not be apparent in controlled laboratory settings. By addressing these factors early in the development cycle, companies can create prototypes that not only meet technical specifications but also excel in practical applications.

Furthermore, leveraging data analytics and machine learning algorithms can streamline the iterative design process. These technologies can help identify patterns, predict potential issues, and suggest optimizations based on historical data and performance metrics, leading to faster and more effective prototype refinement.

Advanced Technologies and Techniques for Quality Assurance

Precision Manufacturing and Rapid Prototyping

Leveraging cutting-edge manufacturing technologies is essential for producing high-quality pre-production prototypes. Advanced CNC machining centers offer unparalleled precision in crafting complex geometries from a wide range of materials. These machines can achieve tight tolerances and superior surface finishes, ensuring that prototypes meet exact specifications.

Rapid prototyping technologies, such as stereolithography (SLA) and selective laser sintering (SLS), have revolutionized the prototyping landscape. These additive manufacturing methods allow for the creation of intricate designs and complex internal structures that would be challenging or impossible to produce using traditional manufacturing techniques. The ability to quickly iterate and produce multiple design variations accelerates the development process while maintaining high quality standards.

Hybrid manufacturing approaches, combining additive and subtractive techniques, offer the best of both worlds. This synergy allows for the rapid production of near-net-shape parts that can then be finished to precise tolerances using traditional machining methods, resulting in prototypes that closely mimic the properties and performance of production parts.

Advanced Metrology and Inspection Techniques

Ensuring dimensional accuracy and consistency in pre-production prototypes requires sophisticated measurement and inspection tools. Coordinate measuring machines (CMMs) provide highly accurate three-dimensional measurements of complex parts, allowing for precise verification of critical dimensions and geometric tolerances.

Optical measurement systems, such as 3D scanners and structured light technologies, offer rapid and non-contact inspection capabilities. These tools are particularly useful for capturing complex freeform surfaces and comparing them to CAD models, enabling quick identification of deviations or manufacturing errors.

Computed tomography (CT) scanning has emerged as a powerful tool for inspecting the internal features of prototypes without destructive testing. This technology allows engineers to visualize and analyze internal structures, detect defects, and verify assembly quality, providing invaluable insights for improving prototype design and manufacturing processes.

Virtual and Augmented Reality in Prototype Evaluation

Virtual reality (VR) and augmented reality (AR) technologies are increasingly being utilized in the prototype evaluation process. These immersive technologies allow designers, engineers, and stakeholders to interact with digital representations of prototypes in a virtual environment, providing a more intuitive understanding of the product's form, fit, and function.

VR simulations can be used to conduct virtual usability tests, allowing companies to gather valuable user feedback on prototype designs without the need for physical models. This approach accelerates the iterative design process and helps identify potential issues early in the development cycle.

AR applications enable the overlay of digital information onto physical prototypes, facilitating more efficient quality inspections and assembly processes. By providing real-time guidance and visual cues, AR can help reduce errors and improve the overall quality of prototype production and evaluation.

Collaborative Approaches to Prototype Quality Management

Cross-Functional Team Integration

Ensuring high-quality pre-production prototypes requires a collaborative effort across various disciplines. Integrating cross-functional teams comprising designers, engineers, manufacturing specialists, and quality assurance experts fosters a holistic approach to prototype development. This diverse skill set allows for comprehensive problem-solving and innovative solutions to quality challenges.

Regular communication and knowledge sharing among team members are crucial for maintaining consistency and addressing potential issues promptly. Implementing collaborative software platforms and project management tools can facilitate seamless information exchange and ensure that all team members are aligned on quality objectives and project milestones.

Encouraging a culture of continuous learning and improvement within the team can lead to enhanced prototype quality over time. This may involve organizing workshops, attending industry conferences, or participating in specialized training programs to stay abreast of the latest advancements in prototyping technologies and quality management practices.

Supplier and Partner Collaboration

Collaborating closely with suppliers and manufacturing partners is essential for maintaining quality throughout the prototyping process. Establishing clear quality standards and expectations with external partners ensures that all components and materials meet the required specifications. Regular audits and quality assessments of supplier processes can help identify potential issues before they impact prototype quality.

Engaging suppliers early in the design process can lead to valuable insights and recommendations for improving manufacturability and quality. Their expertise in specific materials or manufacturing processes can contribute to more refined and production-ready prototypes.

Implementing a robust supply chain management system that includes quality tracking and traceability features can help maintain consistent quality across multiple prototype iterations and ensure that any issues can be quickly traced to their source for prompt resolution.

Customer Feedback Integration

Incorporating customer feedback into the prototyping process is crucial for ensuring that the final product meets user expectations and quality standards. Conducting user testing sessions with pre-production prototypes allows companies to gather valuable insights on usability, ergonomics, and overall user experience.

Utilizing techniques such as focus groups, surveys, and beta testing programs can provide a wealth of qualitative and quantitative data to inform prototype refinement. This feedback loop helps identify potential quality issues or design flaws that may not be apparent during internal testing.

Implementing a structured system for collecting, analyzing, and acting upon customer feedback ensures that valuable insights are not overlooked. This may involve using specialized software tools for tracking and prioritizing feedback, as well as establishing clear processes for incorporating customer-driven improvements into subsequent prototype iterations.

Conclusion

Ensuring quality in pre-production prototypes is a multifaceted process that requires a combination of advanced technologies, rigorous testing, and collaborative approaches. By focusing on precision manufacturing, comprehensive quality control measures, and iterative design processes, companies can create high-quality prototypes that accurately represent the final product. Leveraging cutting-edge inspection techniques, virtual reality tools, and cross-functional teamwork further enhances the ability to identify and resolve potential issues early in the development cycle. Ultimately, investing in prototype quality leads to more successful product launches, reduced time-to-market, and improved customer satisfaction.

FAQs

What are the most critical factors in ensuring prototype quality?

Key factors include precise material selection, advanced manufacturing techniques, comprehensive testing, and iterative design processes.

How does 3D printing technology impact prototype quality?

3D printing enables rapid production of complex designs, allowing for quick iterations and refinements to improve overall prototype quality.

What role does customer feedback play in prototype quality assurance?

Customer feedback provides valuable insights into usability and performance, helping identify quality issues and drive improvements in subsequent iterations.

Expert Prototyping Services for Quality Assurance | BOEN

At BOEN Prototype, we specialize in delivering high-quality pre-production prototypes using advanced manufacturing techniques and rigorous quality control processes. Our experienced team of engineers and designers works closely with clients to ensure precise material selection, comprehensive testing, and iterative refinement. As a leading prototype supplier and manufacturer, we offer a wide range of services including CNC machining, rapid injection molding, and 3D printing to meet your specific prototyping needs. Contact us at contact@boenrapid.com to learn how we can support your product development journey with top-tier prototyping solutions.

References

Smith, J. (2022). "Advanced Techniques in Pre-Production Prototyping." Journal of Manufacturing Technology, 45(3), 112-128.

Johnson, A., & Lee, S. (2021). "Quality Assurance Strategies for Rapid Prototyping." International Journal of Product Development, 18(2), 205-220.

Brown, R. (2023). "The Impact of Virtual Reality on Prototype Evaluation." Product Innovation Management Review, 31(4), 78-95.

Davis, M., & Wilson, K. (2022). "Collaborative Approaches in Prototype Quality Management." Journal of Engineering Design, 33(1), 42-58.

Thompson, L. (2021). "Material Selection Strategies for High-Quality Prototypes." Advanced Materials and Processes, 179(5), 32-40.

Garcia, E., & Patel, N. (2023). "Integrating Customer Feedback in Prototype Development." International Journal of Quality & Reliability Management, 40(2), 189-204.