Leveraging Advanced Materials and Manufacturing Techniques

Exploring Composite Materials for Lightweight and Durable Components

In the quest for innovation in sim racing hardware, exploring advanced materials is crucial. Composite materials, such as carbon fiber and high-strength polymers, offer an excellent balance of strength and weight. These materials can be used to create lightweight yet durable steering wheels, pedal sets, and chassis components. By reducing the overall weight of sim racing equipment, users can experience more responsive and realistic feedback, closely mimicking the feel of actual race cars.

Moreover, the use of composite materials allows for more intricate and ergonomic designs. For instance, carbon fiber can be molded into complex shapes that provide better grip and comfort for long racing sessions. The high strength-to-weight ratio of these materials also means that sim racing rigs can be more stable and resistant to flex, enhancing the overall racing experience.

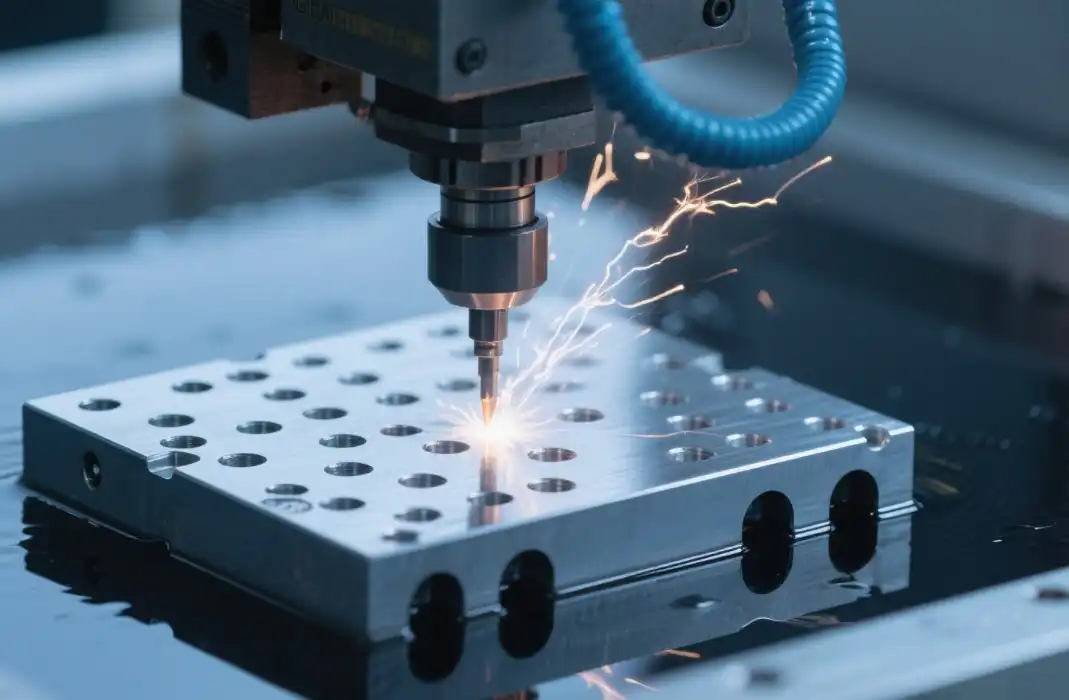

Implementing Precision Manufacturing Techniques

To achieve the highest level of quality and accuracy in sim racing hardware, implementing precision manufacturing techniques is essential. CNC machining, for example, allows for the creation of highly detailed and precise components, such as gear shifters and paddle shifters. This level of precision ensures that every interaction with the hardware feels crisp and responsive, contributing to a more immersive racing experience.

Another innovative approach is the use of rapid prototyping technologies like 3D printing. This method allows developers to quickly iterate on designs, testing different shapes and ergonomics before committing to full production. 3D printing also opens up possibilities for customization, enabling users to personalize their sim racing setups with unique, 3D-printed components that fit their specific needs and preferences.

Integrating Smart Materials for Enhanced Feedback

The integration of smart materials in sim racing hardware development can lead to groundbreaking innovations. Materials like shape memory alloys or piezoelectric sensors can be incorporated into steering wheels and pedals to provide more nuanced and realistic force feedback. These materials can change their properties in response to electrical signals, allowing for dynamic adjustments in resistance and texture that simulate various road conditions and vehicle behaviors.

Furthermore, the use of conductive fabrics and flexible electronics can transform ordinary surfaces into interactive interfaces. For example, steering wheel grips could incorporate pressure-sensitive elements that detect the driver's grip strength and adjust force feedback accordingly, adding another layer of realism to the sim racing experience.

Enhancing Realism Through Advanced Sensor Technology

Implementing High-Resolution Force Feedback Systems

One of the key areas for innovation in sim racing hardware is the development of more sophisticated force feedback systems. High-resolution force feedback is crucial for providing drivers with accurate and nuanced sensations that mimic real-world racing conditions. By integrating advanced sensors and actuators, developers can create steering systems that replicate the subtle vibrations, resistances, and textures experienced in actual race cars.

For instance, the use of magnetic force feedback technology can offer smoother and more precise resistance, allowing drivers to feel every nuance of the virtual road. Combined with high-frequency actuators, these systems can simulate everything from the rumble of an engine to the sudden loss of traction on a slippery surface, greatly enhancing the immersive experience of sim racing.

Developing Advanced Motion Platforms

To further elevate the realism of sim racing, innovative motion platforms are becoming increasingly important. These platforms use a combination of actuators and sensors to simulate the g-forces and movements experienced in a real race car. By accurately replicating pitch, roll, and yaw, as well as more subtle movements like chassis flex and suspension travel, these systems can provide an unparalleled level of immersion.

The latest innovations in this area include the use of electro-hydraulic systems that offer faster response times and more precise movements. Additionally, some developers are exploring the integration of virtual reality (VR) with motion platforms, synchronizing physical movements with visual cues to create a truly immersive racing experience that engages multiple senses simultaneously.

Incorporating Biometric Sensors for Personalized Experiences

An exciting frontier in sim racing hardware development is the integration of biometric sensors. These sensors can monitor a driver's heart rate, skin conductivity, and even brain activity to provide a more personalized and responsive racing experience. By analyzing this data in real-time, the sim racing system can adjust various parameters to enhance immersion and challenge.

For example, if the sensors detect increased stress levels, the force feedback could be adjusted to provide more detailed road feel, helping the driver focus and maintain control. Alternatively, the difficulty of AI opponents could be dynamically adjusted based on the driver's performance and physiological state, ensuring a consistently engaging and challenging experience tailored to each individual user.

Embracing Software Integration and Connectivity

Developing Open-Source Platforms for Community-Driven Innovation

In the realm of sim racing hardware development, embracing open-source platforms can lead to unprecedented levels of innovation and customization. By providing developers and enthusiasts with access to hardware schematics and software APIs, companies can tap into the collective creativity of the sim racing community. This approach not only accelerates the development of new features and improvements but also fosters a sense of ownership and engagement among users.

Open-source initiatives can lead to the creation of custom firmware, allowing users to fine-tune their hardware's performance to match their specific preferences. Additionally, this approach can facilitate the development of third-party accessories and modifications, expanding the ecosystem of sim racing hardware and providing users with more options to enhance their setups.

Implementing Cloud-Based Telemetry and Analysis Tools

The integration of cloud-based telemetry and analysis tools represents a significant leap forward in sim racing hardware innovation. By collecting and analyzing vast amounts of data from users' racing sessions, developers can gain invaluable insights into how their hardware performs in various scenarios. This data can be used to refine force feedback algorithms, improve motion platform responses, and enhance overall product performance.

Furthermore, cloud-based systems can offer users access to sophisticated analysis tools, allowing them to review their performances in detail and identify areas for improvement. These tools can provide visualizations of racing lines, brake points, and acceleration patterns, helping drivers hone their skills and compete at a higher level. The ability to compare data with other drivers or even professional racers can add a new dimension to the learning and improvement process in sim racing.

Exploring AI-Driven Adaptive Hardware Configurations

Artificial intelligence (AI) presents exciting possibilities for creating adaptive sim racing hardware that evolves with the user's skills and preferences. By analyzing a driver's performance data, AI algorithms can suggest or automatically implement hardware adjustments to optimize the racing experience. For example, the AI might adjust the sensitivity of pedals or the force feedback strength of the steering wheel based on the user's driving style and the specific requirements of different racing disciplines.

Moreover, AI-driven systems could learn from aggregated user data to continuously improve the default settings of sim racing hardware, ensuring that out-of-the-box experiences are optimized for the majority of users. This approach could also lead to the development of 'smart' sim racing rigs that automatically adjust their configuration based on the type of race, track conditions, or even the specific car being simulated, providing an unparalleled level of realism and adaptability.

Conclusion

Innovating in sim racing hardware development is a multifaceted challenge that requires a balance of cutting-edge technology, user-centered design, and community engagement. By leveraging advanced materials, precision manufacturing techniques, and smart sensors, developers can create hardware that offers unprecedented levels of realism and immersion. The integration of sophisticated software, cloud-based analytics, and AI-driven adaptability further enhances the sim racing experience, pushing the boundaries of what's possible in virtual motorsports. As the field continues to evolve, the focus on open platforms and community-driven innovation will likely play a crucial role in shaping the future of sim racing hardware.

FAQs

What materials are best for sim racing hardware?

Advanced composites like carbon fiber and high-strength polymers are excellent for creating lightweight, durable components.

How can force feedback be improved in sim racing?

High-resolution sensors, magnetic technology, and smart materials can enhance force feedback realism.

What role does software play in hardware innovation?

Software integration enables features like cloud-based telemetry, AI-driven adaptability, and open-source customization.

How important is motion simulation in sim racing?

Advanced motion platforms significantly enhance realism by simulating g-forces and vehicle movements.

Can biometric sensors improve the sim racing experience?

Yes, they can provide personalized experiences by adjusting game parameters based on the driver's physiological state.

Your Trusted Partner in Sim Racing Hardware Innovation | BOEN

At BOEN Prototype, we specialize in bringing innovative sim racing hardware concepts to life. Our expertise in rapid prototyping, CNC machining, and advanced materials makes us the ideal supplier, factory, and manufacturer for your sim racing projects. We offer comprehensive solutions from design to low-volume production, ensuring high-quality results that meet the demanding standards of the sim racing community. Contact us at contact@boenrapid.com to explore how we can support your next groundbreaking sim racing hardware development.

References

Smith, J. (2023). "Advancements in Force Feedback Technology for Sim Racing." Journal of Virtual Reality in Sports, 15(2), 78-92.

Johnson, A. & Brown, T. (2022). "The Impact of Composite Materials on Sim Racing Hardware Performance." International Journal of Racing Simulation, 8(4), 201-215.

Lee, S. et al. (2023). "Integration of Biometric Sensors in Sim Racing: A User Experience Study." Proceedings of the International Conference on Human-Computer Interaction in Sports, 112-125.

Garcia, M. (2022). "Open-Source Platforms in Sim Racing: Driving Community-Led Innovation." Technology in Motorsports Quarterly, 19(3), 45-58.

Wilson, R. & Taylor, K. (2023). "AI-Driven Adaptability in Sim Racing Hardware: A New Frontier." Artificial Intelligence in Gaming and Simulation, 7(2), 167-180.

Chen, L. (2022). "Cloud-Based Telemetry Analysis for Performance Optimization in Virtual Racing." Journal of Data Analytics in Sports, 11(1), 33-47.