How to Manufacture High-Quality Prototypes Efficiently?

To manufacture high-quality prototypes efficiently, start by selecting the right processes like CNC machining or rapid injection molding for precise results in plastics and metals. Partner with specialists who offer fast turnarounds and material expertise to tackle complex designs. Begin with clear CAD files and detailed specs to streamline production. Use integrated methods such as vacuum casting or SLA 3D printing for quick iterations. Focus on quality control at every step, from material selection to final inspection, ensuring durability and functionality. This approach minimizes waste, reduces costs, and accelerates development in industries like automotive or medical devices. Collaborate closely with your provider for feedback loops that refine prototypes swiftly. By prioritizing efficiency and precision in prototype manufacturing, you achieve reliable models that support successful product launches, saving time and resources along the way.

Essential Steps in Prototype Manufacturing Planning

Planning sets the foundation for efficient prototype manufacturing. It involves mapping out your needs and resources. Think about the end goal and how prototypes fit into your development cycle. Good planning avoids common pitfalls and keeps things moving smoothly. Now, let's break down key aspects to consider.

Defining Project Requirements and Specifications

Clear requirements form the backbone of successful prototype manufacturing, where engineers outline dimensions, tolerances, and performance criteria using detailed CAD models and material datasheets. This precision guides the selection of processes like compression molding for robust plastic parts or metal pressing for sturdy enclosures, ensuring prototypes mirror intended functions in real-world applications such as robotics arms or aerospace brackets. Teams incorporate regulatory standards early, especially in medical devices, to avoid redesigns. Detailed specs facilitate accurate quoting and timelines, allowing providers to recommend optimal materials like high-strength alloys or flexible polymers based on load-bearing needs or environmental exposure. This step integrates feedback from designers, fostering a collaborative environment that aligns prototypes with market demands and innovation goals.

Selecting Appropriate Materials and Processes

Material choice in prototype manufacturing hinges on properties like tensile strength, thermal resistance, or conductivity, with experts advising on plastics for lightweight designs or metals for durability in defense applications. Processes such as die casting excel for intricate metal components, offering fine details and repeatability, while SLS 3D printing suits complex geometries in consumer electronics without tooling costs. Integration of multiple techniques, like combining CNC machining with vacuum casting, enhances efficiency by addressing diverse needs in one workflow. Professionals evaluate factors such as batch size and turnaround, opting for rapid tooling to bridge prototyping to low-volume runs. This selection ensures prototypes withstand testing, providing reliable data for refinements and scaling.

Collaborating with Expert Providers

Partnering with seasoned providers in prototype manufacturing brings amassed knowledge to your project, where they assist in navigating challenges like material compatibility or design optimization for industries ranging from agriculture to electronics. These experts offer end-to-end services, from initial consultations on design mock-ups to final quality assurances, guaranteeing fast turnarounds through streamlined production integration. They provide insights into cost-effective strategies, such as using SLA 3D printing for quick visuals or rapid injection molding for functional tests. Effective collaboration involves regular updates and iterative reviews, ensuring prototypes meet exact specifications. This relationship builds trust, enabling engineers to focus on innovation while relying on proven expertise for high-quality outcomes.

Advanced Techniques for Efficient Prototype Creation

Advanced techniques elevate prototype manufacturing by incorporating cutting-edge tools and methods. They speed up the process while maintaining top-notch quality. These approaches adapt to various industry needs, from quick mock-ups to durable models. Dive into some powerful options available today.

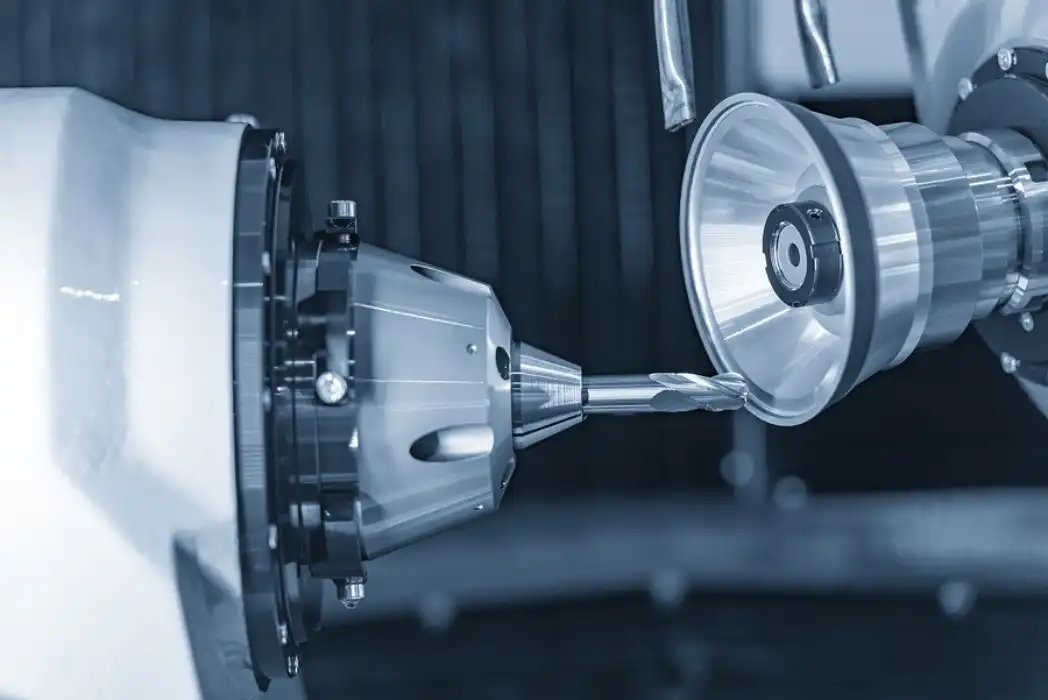

Leveraging CNC Machining and 3D Printing

CNC machining in prototype manufacturing delivers unparalleled precision for metal and plastic parts, utilizing computer-guided tools to carve intricate features with tolerances under 0.01mm, ideal for automotive components or medical enclosures requiring exact fits. Operators program paths that minimize waste, enhancing efficiency in low-volume scenarios. Complementing this, SLA 3D printing builds layers of resin for smooth, detailed surfaces in prototypes like consumer gadget casings, allowing overnight production of complex shapes without molds. SLS variant fuses powders for stronger, functional models in aerospace testing. Combining these technologies enables hybrid prototypes, where machined bases support printed details, accelerating development cycles and reducing iteration times through rapid prototyping capabilities.

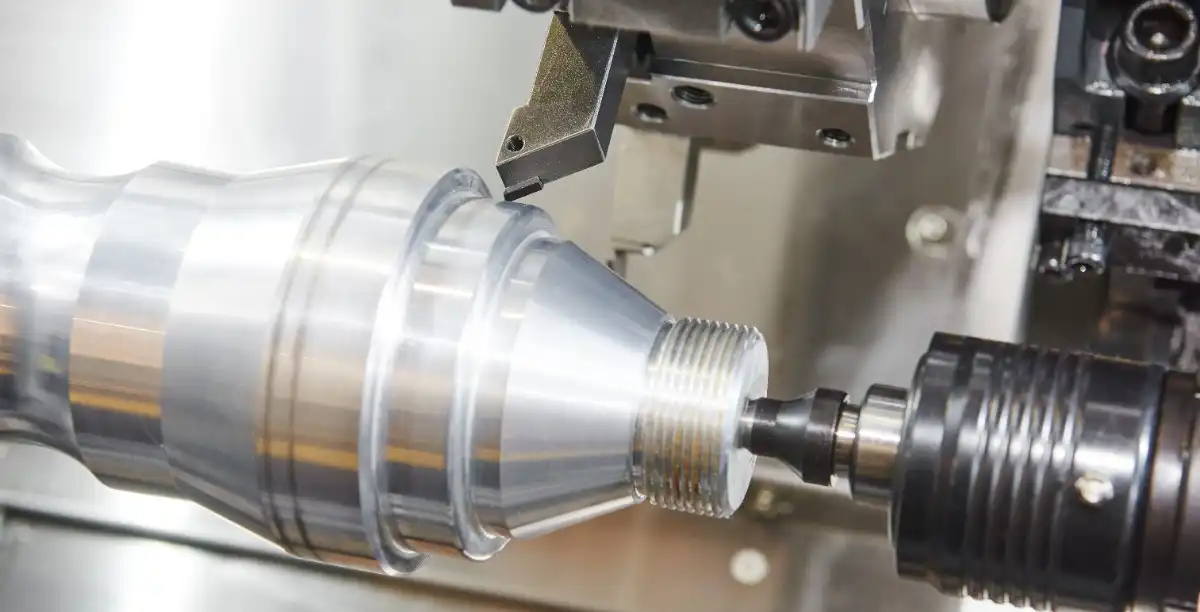

Implementing Rapid Tooling and Molding Methods

Rapid tooling transforms prototype manufacturing by creating molds quickly from aluminum or soft steels, supporting injection molding for small runs of plastic parts that mimic final production quality in sectors like electronics. This method shortens lead times to days, enabling testing of material flow and part ejection in real conditions. Compression molding applies heat and pressure to form composites, suitable for agriculture tools needing impact resistance. Vacuum casting replicates fine textures in silicone molds, producing limited quantities of polyurethane prototypes that simulate end-use plastics. These techniques integrate seamlessly, allowing designers to validate designs economically before committing to expensive production tooling, thus optimizing resource allocation and enhancing overall project efficiency.

Ensuring Quality Control Throughout Production

Quality control in prototype manufacturing involves systematic inspections at each stage, from raw material verification using spectrometers to in-process monitoring with coordinate measuring machines for dimensional accuracy in defense prototypes. Teams implement protocols like statistical process control to detect variances early, preventing defects in critical areas such as surface finish or structural integrity. Final assessments include functional testing under simulated loads, ensuring prototypes perform as expected in robotics applications. Documentation tracks every step, providing traceability for regulatory compliance in medical fields. This rigorous approach guarantees reliability, reduces rework, and builds confidence in the prototypes, ultimately supporting smoother transitions to full manufacturing.

Optimizing the Prototype Manufacturing Workflow

Optimizing your workflow streamlines prototype manufacturing from start to finish. It focuses on efficiency without sacrificing quality. Smart strategies help cut down on delays and boost output. Let's explore ways to refine this process for better results.

Streamlining Design and Iteration Cycles

Streamlining design cycles in prototype manufacturing relies on agile methodologies, where digital simulations via finite element analysis predict behaviors before physical creation, minimizing errors in complex assemblies for automotive robotics. Iterative loops incorporate rapid feedback, using design mock-ups to test ergonomics or aesthetics quickly. Software tools enable version control, allowing teams to compare changes and select optimal configurations. In consumer electronics, this means refining circuit housings through successive 3D printed versions, each incorporating user input. Efficient workflows integrate CAD updates directly into production queues, reducing downtime and accelerating refinements. This method fosters innovation, ensuring prototypes evolve swiftly to meet evolving specifications and market needs.

Managing Costs and Timelines Effectively

Effective cost management in prototype manufacturing starts with value engineering, analyzing components to eliminate unnecessary features while preserving functionality, such as optimizing material thickness in aerospace parts for weight savings. Timeline oversight uses Gantt charts to sequence tasks, aligning CNC machining with subsequent molding to avoid bottlenecks. Bulk purchasing of standard materials lowers expenses, while modular designs allow reusable elements across prototypes. In agriculture, this approach delivers cost-effective tool prototypes within tight seasonal windows. Providers offer scalable services, adjusting for volume to balance budgets. Regular progress reviews identify overruns early, enabling adjustments that keep projects on track and within financial limits.

Scaling from Prototypes to Low-Volume Production

Scaling in prototype manufacturing transitions smoothly to low-volume production by refining processes tested in initial models, such as adapting rapid injection molding for small batches in medical enclosures. This phase incorporates lessons from prototype testing, like material durability under stress, to enhance tooling for efficiency. Integration of automation in die casting ensures consistency as quantities increase modestly. Teams plan for scalability by designing prototypes with production in mind, minimizing changes. In defense, this means secure, repeatable runs that maintain quality. The shift supports market validation, producing enough units for trials while controlling costs, paving the way for eventual mass output if demand grows.

Conclusion

Manufacturing high-quality prototypes efficiently demands careful planning, advanced techniques, and optimized workflows in prototype manufacturing. Select suitable materials and processes, collaborate with experts, and maintain strict quality controls. Streamline iterations and manage resources wisely to scale effectively. This method accelerates development and reduces risks across industries. Embrace these strategies for superior results and competitive advantages.

FAQs

How does prototype manufacturing work?

It involves creating models using techniques like CNC machining, rapid injection molding, or 3D printing to test designs in plastics and metals.

What are the benefits?

It supports quick iterations, cost savings, and quality assurance in product development for sectors like automotive and aerospace.

Which processes are best for efficiency?

Options such as vacuum casting, die casting, and SLS 3D printing offer fast turnarounds and precision.

How to ensure high quality?

Implement controls from material selection to final testing, leveraging expert knowledge.

Can it scale to low-volume?

Yes, integrated methods bridge prototyping to small-batch manufacturing seamlessly.

What industries use it?

Fields including medical devices, consumer electronics, and agriculture benefit from customized solutions.

Mastering How to Manufacture High-Quality Prototypes Efficiently | BOEN

At BOEN, we lead as a prototype manufacturing supplier and manufacturer, specializing in high-quality plastic and metal solutions worldwide. Our services in CNC machining, rapid tooling, and low-volume production empower industries from robotics to agriculture with swift turnarounds and innovative fixes. We guarantee precision and efficiency to advance your developments. Connect with us at contact@boenrapid.com for expert collaboration.

References

"Prototyping and Low-Volume Production: The Essential Guide" by Rob Thompson.

"Rapid Prototyping: Principles and Applications" by Chua Chee Kai, Leong Kah Fai, and Lim Chu-Sing.

"CNC Machining Handbook: Building, Programming, and Implementation" by Alan Overby.

"Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing" by Ian Gibson, David Rosen, and Brent Stucker.

"Injection Molding Handbook" by Dominick V. Rosato and Donald V. Rosato.

"Product Design for Manufacture and Assembly" by Geoffrey Boothroyd, Peter Dewhurst, and Winston A. Knight.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.