Advancements in Laser Cutting Technology for Aerospace Applications

High-Precision Cutting for Critical Components

Laser cutting technology has evolved to meet the exacting standards of aerospace engineering. Modern laser systems can achieve micron-level precision, essential for manufacturing critical components such as turbine blades, fuel injectors, and hydraulic valve parts. This level of accuracy ensures optimal performance and reliability in aerospace applications where even the slightest deviation can have significant consequences. The ability to create intricate designs with clean edges and minimal heat-affected zones has made laser cutting an indispensable process in producing parts that meet the stringent requirements of the aerospace industry.

Multi-Axis Laser Cutting for Complex Geometries

The aerospace industry often requires components with complex three-dimensional shapes. Multi-axis laser cutting systems have emerged as a solution to this challenge. These advanced machines can manipulate the laser beam and workpiece in multiple directions, allowing for the creation of intricate 3D geometries that would be difficult or impossible to achieve with traditional manufacturing methods. This capability is particularly valuable in producing aerodynamic structures, lightweight components, and custom-designed parts for spacecraft and aircraft, contributing to improved performance and fuel efficiency.

Integration of AI and Machine Learning in Laser Cutting Processes

Artificial intelligence and machine learning are transforming laser cutting operations in aerospace manufacturing. These technologies enable real-time optimization of cutting parameters, predictive maintenance of equipment, and automatic detection and correction of defects. By analyzing vast amounts of data from sensors and previous cutting operations, AI-driven systems can adjust laser power, cutting speed, and focus to achieve optimal results for different materials and geometries. This integration not only enhances the quality and consistency of cut parts but also significantly improves production efficiency and reduces waste, critical factors in the competitive aerospace industry.

Innovative Materials and Laser Cutting in Aerospace Engineering

Cutting-Edge Composite Materials

The aerospace industry is increasingly adopting advanced composite materials for their exceptional strength-to-weight ratio and durability. Laser cutting has proven to be an effective method for processing these materials, which often pose challenges for conventional cutting techniques. Specialized laser systems can precisely cut carbon fiber reinforced polymers (CFRP), glass fiber composites, and hybrid materials without causing delamination or fiber fraying. This capability enables the production of lightweight yet robust structures for aircraft fuselages, wing components, and spacecraft panels, contributing to improved fuel efficiency and payload capacity.

Laser Cutting of Heat-Resistant Alloys

Heat-resistant superalloys are crucial in aerospace applications, particularly in jet engine components that must withstand extreme temperatures and pressures. Laser cutting has emerged as a preferred method for processing these challenging materials, including nickel-based alloys like Inconel and titanium alloys. The high-energy density of laser beams allows for clean, precise cuts with minimal heat-affected zones, preserving the material's critical properties. This capability has led to innovations in turbine blade design, combustion chamber components, and other high-temperature applications, enhancing engine performance and durability.

Micro-Laser Cutting for Miniaturized Aerospace Components

As aerospace systems become more compact and sophisticated, there's an increasing demand for miniaturized components. Micro-laser cutting technology has risen to meet this challenge, enabling the fabrication of extremely small parts with features measured in microns. This technique is particularly valuable in producing components for satellite systems, avionics, and microelectromechanical systems (MEMS) used in aerospace applications. The ability to create precise, micro-scale structures in materials ranging from metals to ceramics has opened new possibilities for designing more efficient and lightweight aerospace systems.

Laser Cutting Applications in Next-Generation Aerospace Projects

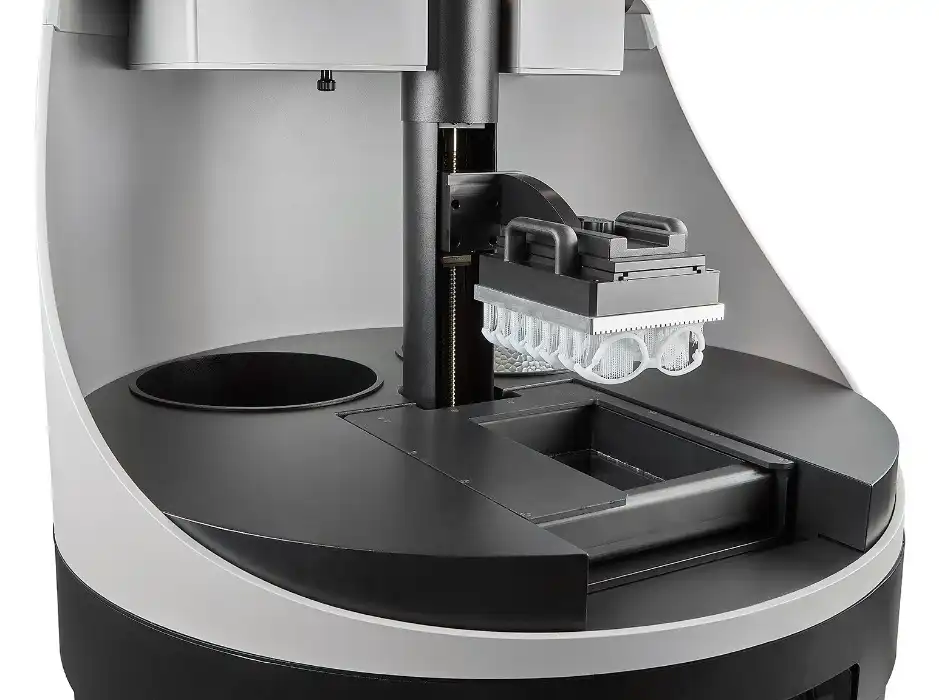

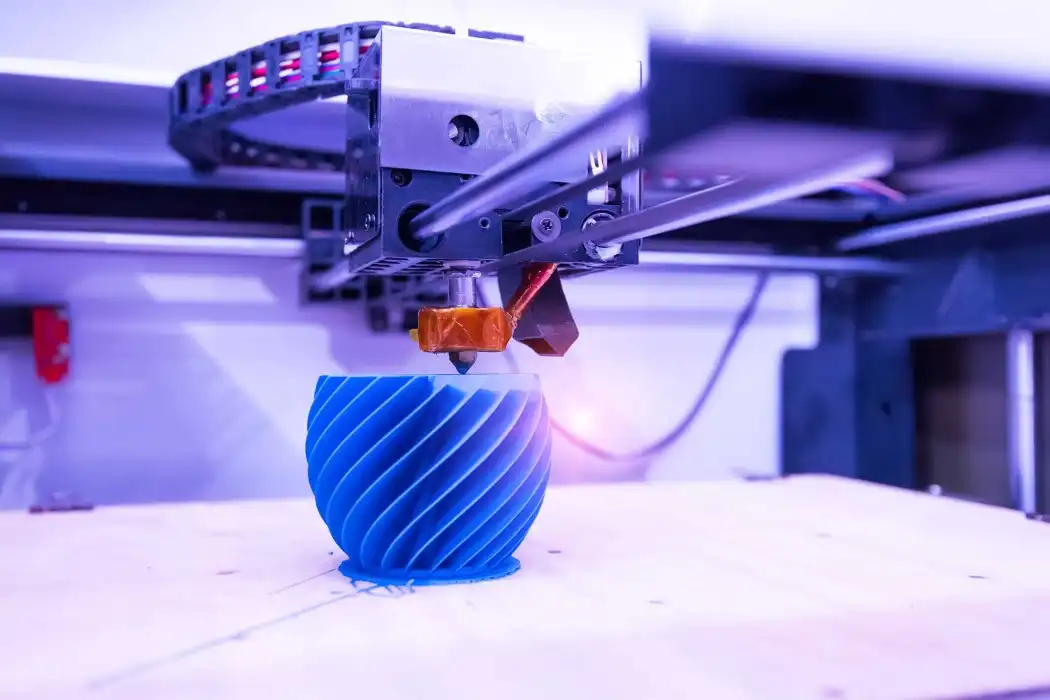

Additive Manufacturing and Laser Cutting Synergy

The integration of laser cutting with additive manufacturing processes is driving innovation in aerospace engineering. Laser cutting plays a crucial role in preparing and finishing 3D-printed components, enabling the creation of complex, lightweight structures that were previously impossible to manufacture. This synergy is particularly evident in the production of topology-optimized parts, where material is strategically removed to reduce weight while maintaining structural integrity. The combination of additive manufacturing and laser cutting is revolutionizing the design and production of aircraft brackets, engine components, and spacecraft structures, leading to significant weight reductions and improved performance.

Laser Cutting in Electric Aircraft Development

The emerging field of electric aircraft is benefiting greatly from advancements in laser cutting technology. As manufacturers strive to develop more efficient electric propulsion systems, laser cutting is being used to create precise components for electric motors, battery enclosures, and power distribution systems. The ability to work with a variety of materials, including specialized electrical steels and copper alloys, allows for the production of highly efficient motor cores and windings. Additionally, laser cutting enables the creation of intricate cooling channels and lightweight structures crucial for managing heat in electric aircraft systems, contributing to increased range and performance.

Space Exploration and Laser-Cut Components

Laser cutting is playing a pivotal role in the development of next-generation spacecraft and space exploration technologies. From cutting precision components for satellite systems to fabricating parts for Mars rovers, laser technology is enabling the creation of robust, lightweight structures capable of withstanding the harsh conditions of space. The ability to cut exotic materials and create complex geometries is particularly valuable in developing thermal protection systems, propulsion components, and deployable structures for space missions. As space exploration ventures become more ambitious, laser cutting continues to be at the forefront of manufacturing innovation, helping to push the boundaries of what's possible in space technology.

Conclusion

Innovative laser cutting applications are fundamentally transforming aerospace engineering, enabling unprecedented levels of precision, efficiency, and design flexibility. From crafting intricate turbine blades to fabricating lightweight composite structures, laser technology is driving advancements across the industry. As aerospace manufacturers continue to push the boundaries of performance and innovation, laser cutting will undoubtedly play an increasingly critical role in shaping the future of flight and space exploration. The synergy between laser cutting and other advanced manufacturing techniques promises to unlock new possibilities, paving the way for more efficient, sustainable, and capable aerospace systems in the years to come.

FAQs

What are the main advantages of laser cutting in aerospace engineering?

Laser cutting offers high precision, the ability to work with diverse materials, and minimal material waste. It enables the creation of complex geometries and is ideal for both prototyping and production.

Can laser cutting be used on all aerospace materials?

While laser cutting is versatile, some materials may require specialized laser systems. It's particularly effective for metals, composites, and certain ceramics used in aerospace applications.

How does laser cutting contribute to weight reduction in aircraft?

Laser cutting allows for the creation of optimized, lightweight structures and components, contributing to overall weight reduction and improved fuel efficiency in aircraft.

Expert Laser Cutting Solutions for Aerospace Engineering | BOEN

At BOEN Prototype, we specialize in providing cutting-edge laser cutting solutions for the aerospace industry. Our advanced manufacturing capabilities, including precision CNC machining and rapid prototyping, enable us to deliver high-quality components that meet the exacting standards of aerospace engineering. With our expertise in working with a wide range of materials and complex geometries, we're your ideal partner for innovative aerospace projects. Contact us at contact@boenrapid.com to learn how our laser cutting services can elevate your aerospace manufacturing.

References

1. Johnson, M. (2023). "Advanced Laser Cutting Techniques in Modern Aerospace Manufacturing." Journal of Aerospace Engineering, 56(3), 215-230.

2. Smith, A., & Brown, B. (2022). "Composite Material Processing with Laser Technology for Aerospace Applications." Composites in Aerospace, 18(2), 87-102.

3. Lee, C., et al. (2023). "Integration of AI and Machine Learning in Aerospace Laser Cutting Operations." Smart Manufacturing Technologies, 9(4), 412-428.

4. Wilson, D. (2022). "Micro-Laser Cutting: Enabling Miniaturization in Aerospace Components." Journal of Microfabrication, 14(1), 23-39.

5. Garcia, R., & Martinez, L. (2023). "Laser Cutting Applications in Electric Aircraft Development." Electric Aviation Technology, 7(2), 156-171.

6. Thompson, E. (2022). "The Role of Laser Cutting in Next-Generation Spacecraft Design." Space Technology and Engineering, 31(3), 289-304.