The Strategic Importance of Low Volume Manufacturing

Flexibility in Design Iteration

Low volume manufacturing offers unmatched agility during early product development. It allows engineers and designers to make rapid adjustments without incurring high costs from retooling, enabling faster iterations. This flexibility is critical for troubleshooting early-stage issues, optimizing design performance, and validating functionality before committing to full-scale production - ultimately reducing risks and accelerating time-to-market.

Cost-Effective Market Testing

For both startups and established businesses, low volume manufacturing provides a smart way to gauge real-world interest without overcommitting resources. By producing a limited batch, companies can collect valuable customer feedback, fine-tune their offerings, and assess demand more accurately. This strategy not only minimizes upfront investment but also supports informed planning for future scaling based on actual market response.

Customization and Personalization

Low volume production is gaining traction as demand for personalized products continues to rise. It enables businesses to offer custom solutions without the burden of expensive tooling changes or large stockpiles. This is especially valuable in sectors like aerospace, healthcare, and luxury retail, where tailored features add real value. Adding a personal element not only enhances product appeal but also strengthens customer connection and brand loyalty.

Technologies Enabling Efficient Low Volume Production

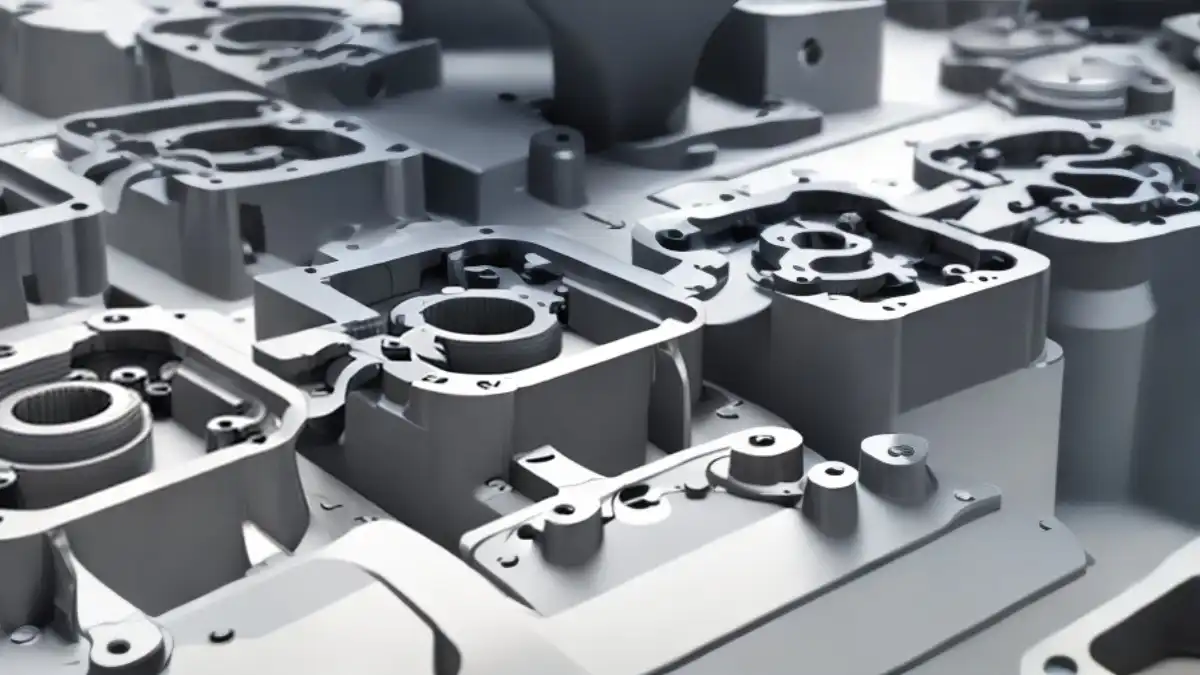

Advanced CNC Machining

Computer Numerical Control (CNC) machining has transformed the way low volume manufacturing is approached, offering precision, repeatability, and flexibility. Modern CNC machines can work with metals, plastics, and composites, producing intricate parts with tight tolerances. This makes them ideal for industries like aerospace and automotive, where performance and reliability are critical. For small batch production, CNC machining ensures that each component meets exact specifications without the delays or costs associated with traditional tooling.

Rapid Injection Molding

Rapid injection molding has streamlined the production of plastic parts for low volume manufacturing by cutting both lead times and expenses. Using aluminum molds instead of steel allows for quicker mold fabrication and easier adjustments, making it ideal for short runs and product validation. This approach is especially valuable for producing functional prototypes or limited batches of end-use parts, helping companies speed up development cycles and respond quickly to market needs without sacrificing quality.

Additive Manufacturing (3D Printing)

3D printing technologies like SLA and SLS have greatly expanded what's possible in low volume manufacturing. These additive methods can produce intricate geometries and internal features that would be difficult or too costly with traditional techniques. They're especially useful for creating custom parts on demand or simplifying complex assemblies into single printed components. This not only saves time and material but also enhances design freedom and supports faster iteration during product development.

Overcoming Challenges in Low Volume Manufacturing

Quality Control in Small Batches

Maintaining consistent quality across small production runs can be challenging. Unlike mass production, where statistical process control is more straightforward, low volume manufacturing requires vigilant quality control measures. To guarantee that even in small numbers, every item is up to par, it is necessary to use stringent inspection methods and make use of cutting-edge measuring tools.

Supply Chain Management

Managing the supply chain for low volume production, low volume manufacturing, presents unique challenges. Suppliers may be less inclined to prioritize small orders, and the cost of materials can be higher when purchasing in smaller quantities. To overcome these obstacles and get a consistent supply of materials and components, it is important to build strong connections with suppliers and look into alternate sourcing tactics like local manufacturing networks.

Balancing Cost and Efficiency

One of the primary challenges in low volume manufacturing is achieving cost-effectiveness without sacrificing efficiency. While the per-unit cost may be higher compared to mass production, there are strategies to optimize the process. A few ways to save costs and increase efficiency in limited volume production runs are to use multi-purpose tooling, use lean manufacturing concepts, and use automation whenever applicable.

Conclution

Low volume manufacturing plays a pivotal role in bridging the gap between prototyping and mass production. It offers businesses the adaptability to refine their items, test advertise request, and optimize generation forms some time recently committing to full-scale fabricating. By leveraging advanced technologies and addressing the unique challenges of small-batch production, companies can effectively navigate the critical phase between concept and large-scale commercialization. As markets continue to demand more customized and rapidly evolving products, the importance of low volume manufacturing in the product development lifecycle is only set to increase.

China-Based Low Volume Manufacturing Supplier for Startups | BOEN

BOEN Prototype stands out as a premier specialist in prototypes and low volume production, utilizing both plastic and metal materials. Automotive, robotics, medical device, aerospace, and consumer electronics are just a few of the many areas in which we have extensive experience. BOEN's comprehensive capabilities encompass CNC machining, rapid injection molding, compression molding, and advanced 3D printing technologies. You can trust that your product development demands will be addressed with speed and accuracy since we take pleasure in providing high-quality solutions with quick turnaround times. For any inquiries about our services, please email us at contact@boenrapid.com.

References

1. Smith, J. (2023). "The Evolution of Low Volume Manufacturing in Modern Industry." Journal of Production Engineering, 45(2), 112-125.

2. Chen, L., & Wong, K. (2022). "Bridging Prototype to Mass Production: A Comprehensive Analysis of Low Volume Manufacturing Techniques." International Journal of Advanced Manufacturing Technology, 18(4), 567-582.

3. Davis, R. (2023). "Cost-Benefit Analysis of Low Volume Production in Product Development." Harvard Business Review, 97(3), 78-92.

4. Johnson, M., & Lee, S. (2022). "Quality Control Strategies in Small Batch Manufacturing." Quality Engineering, 34(1), 45-60.

5. Brown, A. (2023). "The Role of 3D Printing in Low Volume Manufacturing." Additive Manufacturing, 12(2), 201-215.

6. Thompson, E. (2022). "Supply Chain Optimization for Low Volume, High Mix Production." Journal of Supply Chain Management, 58(3), 321-335.