Understanding Low Volume Production and RIM

What is Low Volume Production

Low volume production refers to a manufacturing strategy focused on producing limited quantities of components or products, generally between 10 to 1000 units. It serves as an efficient solution for prototypes, custom orders, or small-batch market launches without the high costs and commitments of mass production. Businesses benefit from its adaptability, reduced initial investment, and faster time-to-market. Common technologies employed in low volume production include CNC machining, 3D printing, and vacuum casting, which support iterative design changes and functional testing before full-scale production.

Exploring Reaction Injection Molding (RIM)

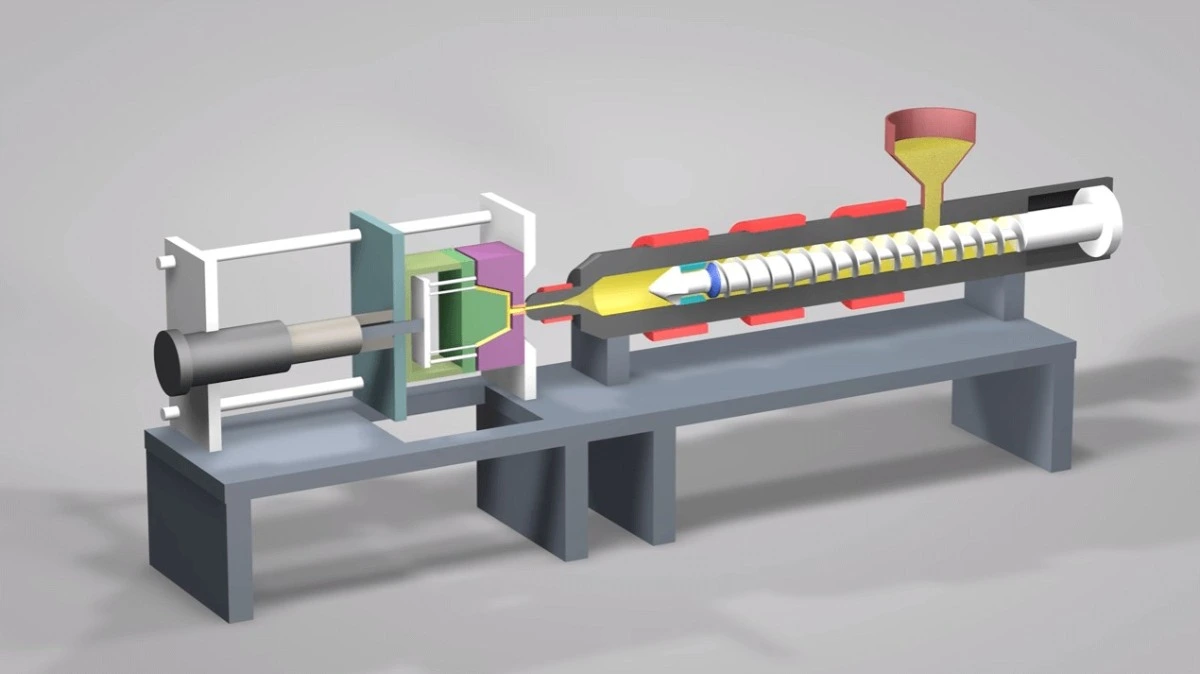

Reaction Injection Molding (RIM) is a versatile manufacturing process wherein two liquid polymer precursors are injected into a mold, triggering a chemical reaction that forms a solid, high-performance part. It is especially suited for low volume production, producing large, lightweight, yet structurally robust components with complex geometries and tailored material properties - such as impact resistance, thermal insulation, or flexibility. RIM is widely used in automotive, medical, and consumer goods industries for parts like housings, panels, and enclosures that require durability and design freedom.

Key Characteristics of Both Methods

While both low volume production and RIM cater to specialized manufacturing needs, they differ in application, scale, and technical requirements. Low volume production emphasizes flexibility, speed, and cost-efficiency for small batches, often using subtractive or additive processes. In contrast, RIM is a molded process ideal for medium-sized series of large, complex parts with homogeneous material properties. It involves higher tooling costs but offers superior surface finish and structural consistency compared to many low-volume approaches.

Comparing Low Volume Production and RIM

Production Speed and Efficiency

Low-volume production techniques, such as 3D printing and CNC machining, are designed for rapid iteration and accelerated timelines. These methods minimize setup requirements and enable quick adjustments, making them particularly suitable for prototyping and small-batch launches. In contrast, Reaction Injection Molding (RIM) involves longer initial setup and mold preparation times. However, once operational, it delivers high-speed output for large, complex components with consistent quality. This makes RIM more efficient for sustained production of intricate geometries, though less agile for immediate, small-scale needs.

Cost Considerations

In low volume production, when producing limited quantities, low-volume methods reduce upfront expenses through simplified tooling and adaptable processes. There is no need for high-cost molds, making short runs economically viable. Conversely, RIM requires significant initial investments in mold creation and machinery setup. Yet, these costs are distributed across larger production volumes, improving per-unit pricing for big batches. Therefore, RIM becomes increasingly cost-competitive for high-quantity orders - especially for large, complex parts that are otherwise expensive to manufacture.

Material Options and Properties

Low-volume production supports extensive material versatility, including engineering-grade thermoplastics, metals, and composites. This allows designers to tailor mechanical, thermal, or aesthetic properties to specific applications. RIM, on the other hand, primarily uses thermoset polymers like polyurethane, which offer distinct advantages such as high structural strength, impact resistance, thermal insulation, and flexibility in durometer. Material selection ultimately depends on functional requirements: low-volume processes favor design flexibility, while RIM is ideal for durable, high-performance components.

Applications and Industries

Low Volume Production Applications

Low volume production is essential in sectors that demand rapid prototyping, bespoke solutions, or limited batch runs. It supports industries like aerospace, automotive prototyping, and medical device manufacturing, where iterative design adjustments and functional testing are fundamental to development. This approach reduces initial costs and shortens lead times, allowing for greater flexibility and innovation. It is especially beneficial for products requiring custom features, limited editions, or market validation before full-scale production.

RIM Applications

Reaction Injection Molding (RIM) is particularly suited for low volume production of large, intricate parts with specific performance characteristics. It is widely used in automotive manufacturing for components such as bumpers and body panels, in construction for insulated structural elements, and in consumer goods for high-quality furniture and enclosures. RIM offers exceptional design freedom, allowing for the integration of rigid or flexible material properties, improved impact resistance, thermal insulation, and customized aesthetic finishes.

Choosing the Right Method for Your Project

The decision between low volume production and RIM depends on several key factors: intended production scale, part size, complexity, material properties, and budget. Low volume methods are ideal for prototypes and small batches, while RIM is better suited for larger, complex parts requiring specific physical properties. Engaging with manufacturing specialists early in the design process can help align project goals with the most efficient and cost-effective production method.

Conclusion

Low volume production and Reaction Injection Molding (RIM) each offer distinct advantages in the manufacturing landscape. While low volume production provides flexibility and cost-effectiveness for small batches and prototypes, RIM excels in creating large, complex parts with specific material properties. Understanding these differences is crucial for manufacturers to make informed decisions about their production processes. By carefully considering project requirements, businesses can leverage the strengths of each method to optimize their manufacturing strategies and bring innovative products to market efficiently.

FAQs

What is the main difference between low volume production and RIM?

Low volume production is ideal for small batches (10-1000 units) and offers flexibility, while RIM specializes in large, complex parts with specific material properties.

Which industries benefit most from low volume production?

Aerospace, automotive prototyping, and medical device development often utilize low volume production for rapid prototyping and testing.

What types of products are best suited for RIM?

RIM is excellent for large parts like automotive bumpers, insulated panels, and furniture components requiring specific material properties.

Low Volume Production vs RIM: Making the Right Choice | BOEN

At BOEN, we specialize in both low volume production and RIM technologies, offering comprehensive solutions for your manufacturing needs. Our expertise spans various industries, including automotive, medical, and consumer electronics. We provide tailored advice to help you choose the most suitable process for your project, ensuring optimal quality, cost-effectiveness, and efficiency. Contact us at contact@boenrapid.com to explore how our advanced manufacturing capabilities can bring your ideas to life.

References

1. Johnson, M. (2022). Advanced Manufacturing Processes: A Comprehensive Guide.

2. Smith, R. L. (2021). Low Volume Production: Strategies for Rapid Market Entry.

3. Thompson, A. K. (2023). Reaction Injection Molding: Innovations and Applications.

4. Williams, E. (2022). Comparative Analysis of Manufacturing Techniques for Small-Scale Production.

5. Chen, L. (2023). Material Science in Modern Manufacturing: From Prototypes to Production.

6. Davis, H. R. (2021). Cost-Effective Manufacturing: Balancing Quality and Efficiency in Small Batch Production.