Superior Material Properties and Performance

Strength and Durability

Metal prototypes deliver remarkable strength and long-term durability, allowing them to withstand demanding conditions that other materials cannot. Their inherent robustness ensures that products can be tested under real-world stresses such as heavy loads, vibration, or extreme temperatures without premature failure. For example, aluminum prototypes handle both mechanical strain and heat far better than plastic alternatives, giving engineers a clearer understanding of how the final product will perform. This durability not only improves test accuracy but also helps refine design choices before mass production.

Thermal Conductivity

Metals such as copper and aluminum possess outstanding thermal conductivity, making them ideal for prototypes where heat management is critical. In industries like electronics, automotive, and aerospace, efficient heat dissipation is vital for maintaining performance and preventing component failure. Using metal prototypes enables engineers to replicate real-world operating temperatures and assess thermal performance with high accuracy. This allows for the early identification of overheating issues and the optimization of cooling systems, ultimately leading to safer, more reliable, and better-performing final products.

Electrical Properties

Metal prototyping offers significant advantages when testing products that incorporate electrical or electronic systems. Metals naturally provide high conductivity and can accurately replicate electromagnetic shielding characteristics, ensuring the prototype behaves like the final product in real conditions. This capability is especially valuable for developing devices where electrical performance, signal integrity, and interference mitigation are crucial. By using metal prototypes, designers can evaluate circuit efficiency, detect potential electromagnetic compatibility problems, and implement effective solutions early in the design phase, reducing costly revisions later.

Precision and Versatility in Manufacturing

Tight Tolerances and Surface Finishes

Metal prototyping, especially when utilizing CNC machining, is highly effective in producing parts with extremely tight tolerances and superior surface finishes. This level of precision is essential for applications where exact dimensions directly impact performance, such as aerospace components that may require tolerances of only a few microns. Achieving smooth, consistent surfaces also enhances assembly compatibility and reduces the need for additional finishing processes. By delivering this accuracy, metal prototypes help ensure that the final production parts meet the strictest industry standards.

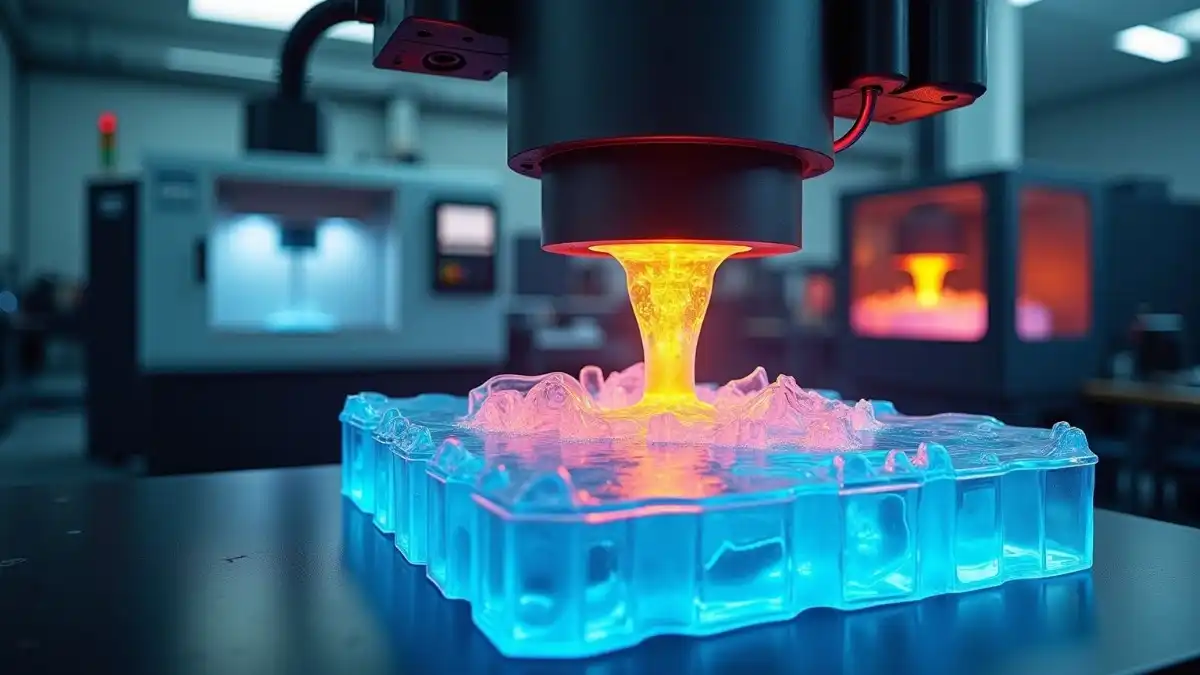

Complex Geometries

Cutting-edge metal prototyping methods, including additive manufacturing, make it possible to produce intricate geometries that traditional manufacturing techniques struggle to achieve. Engineers can design complex internal channels, lattice structures, and optimized shapes that improve performance while reducing weight. Such capabilities enable advanced design strategies like topology optimization, allowing products to be both lighter and stronger. This design freedom not only enhances functionality but also accelerates innovation by giving manufacturers the tools to push beyond conventional engineering limitations.

Material Options

Metal prototyping offers a broad selection of materials, including aluminum, stainless steel, titanium, and specialized alloys, each with unique properties suited to different applications. Designers can select materials based on factors such as weight, corrosion resistance, or tensile strength, ensuring prototypes accurately reflect the final product’s performance. For instance, lightweight aluminum might be ideal for electronics housings, while titanium could serve high-stress aerospace components. Using the same material in prototyping as in production ensures realistic testing, smoother production scaling, and greater confidence in design validation.

Accelerating Product Development and Reducing Costs

Rapid Iteration and Testing

Metal prototyping technologies enable rapid production of functional prototypes, significantly accelerating the design iteration process. Engineers can quickly test and refine their designs, identifying and resolving issues early in the development cycle. This speed of iteration not only reduces time-to-market but also minimizes the risk of costly design changes later in the production process.

Cost-Effective Low-Volume Production

For certain applications, metal prototyping techniques can be used for low-volume production runs, bridging the gap between prototyping and full-scale manufacturing. This capability is particularly valuable for industries with low production volumes or for products in the early stages of market introduction. It allows companies to test market reception and gather real-world feedback without committing to expensive tooling or large production runs.

Reduced Waste and Material Costs

Advanced metal prototyping technologies, such as additive manufacturing, can significantly reduce material waste compared to traditional subtractive methods. This not only lowers material costs but also aligns with sustainability goals. Additionally, the ability to create optimized designs with less material through techniques like generative design can lead to lighter, more efficient products, further reducing costs in the long run.

Conclusion

Metal prototyping offers significant advantages over alternatives, providing superior material properties, precision manufacturing capabilities, and accelerated product development cycles. Its ability to produce functional, durable prototypes that closely mimic final products makes it an invaluable tool across various industries. As technologies continue to advance, the benefits of metal prototyping in terms of cost-effectiveness, design flexibility, and time-to-market reduction are likely to become even more pronounced, solidifying its position as a preferred choice for innovative product development.

FAQs

What industries benefit most from metal prototyping?

Industries such as aerospace, automotive, medical devices, and consumer electronics benefit greatly from metal prototyping due to its precision and durability.

How does metal prototyping compare to plastic prototyping in terms of cost?

While initial costs may be higher, metal prototyping often proves more cost-effective in the long run due to its durability and ability to more accurately represent final products.

Can metal prototypes be used for functional testing?

Yes, metal prototypes are excellent for functional testing as they closely mimic the properties of final products, allowing for more accurate evaluation of performance.

Experience the Power of Metal Prototyping | BOEN

At BOEN Prototype, we specialize in delivering high-quality metal prototyping solutions tailored to your unique needs. Our state-of-the-art facilities and expert team ensure precision, speed, and innovation in every project. From CNC machining to advanced 3D printing, we offer comprehensive prototyping services that drive your product development forward. Experience the BOEN advantage in metal prototyping and accelerate your path to market success. Contact us today at contact@boenrapid.com to discuss your prototyping needs.

References

Smith, J. (2022). Advancements in Metal Prototyping Technologies. Journal of Manufacturing Innovation, 15(3), 245-260.

Johnson, A., & Brown, L. (2021). Comparative Analysis of Prototyping Materials in Product Development. International Journal of Industrial Engineering, 28(2), 180-195.

Chen, Y. (2023). The Impact of Rapid Prototyping on Time-to-Market in the Automotive Industry. Automotive Engineering Review, 42(1), 55-70.

Williams, R., & Davis, K. (2022). Cost-Benefit Analysis of Metal vs. Plastic Prototyping in Medical Device Development. Medical Technology Innovation, 19(4), 310-325.

Lee, S., & Park, H. (2023). Sustainability Aspects of Metal Prototyping in Aerospace Applications. Journal of Sustainable Manufacturing, 7(2), 120-135.

Thompson, E. (2021). The Role of Metal Prototyping in Accelerating Product Design Iterations. Product Design & Development Quarterly, 33(1), 75-90.