The Importance of Aerospace Parts Machining for Industry Standards

Aerospace parts machining plays a crucial role in maintaining industry standards and ensuring the safety and reliability of aircraft and spacecraft. This precision manufacturing process involves creating complex components with tight tolerances, using advanced CNC machining techniques. The aerospace industry relies heavily on high-quality, precisely machined parts to meet strict regulatory requirements and performance standards. From critical engine components to structural elements, aerospace machining contributes significantly to the overall integrity and efficiency of aircraft systems. By adhering to rigorous industry standards, aerospace parts machining helps enhance flight safety, improve fuel efficiency, and drive technological advancements in the aviation and space exploration sectors.

The Evolution of Aerospace Machining Technologies

Traditional Machining Methods in Aerospace

In the early days of aviation, aerospace parts were primarily crafted using manual machining techniques. Skilled machinists relied on lathes, mills, and drills to shape metal components with precision. These methods, while effective, were time-consuming and limited in their ability to produce complex geometries. As aircraft designs became more sophisticated, the need for more advanced manufacturing processes became apparent.

The Rise of CNC Machining in Aerospace

The introduction of Computer Numerical Control (CNC) aerospace parts machining revolutionized the aerospace industry. CNC technology allowed for the automation of machining processes, significantly improving accuracy, repeatability, and efficiency. This advancement enabled manufacturers to produce intricate aerospace components with unprecedented precision, meeting the increasingly stringent requirements of modern aircraft design.

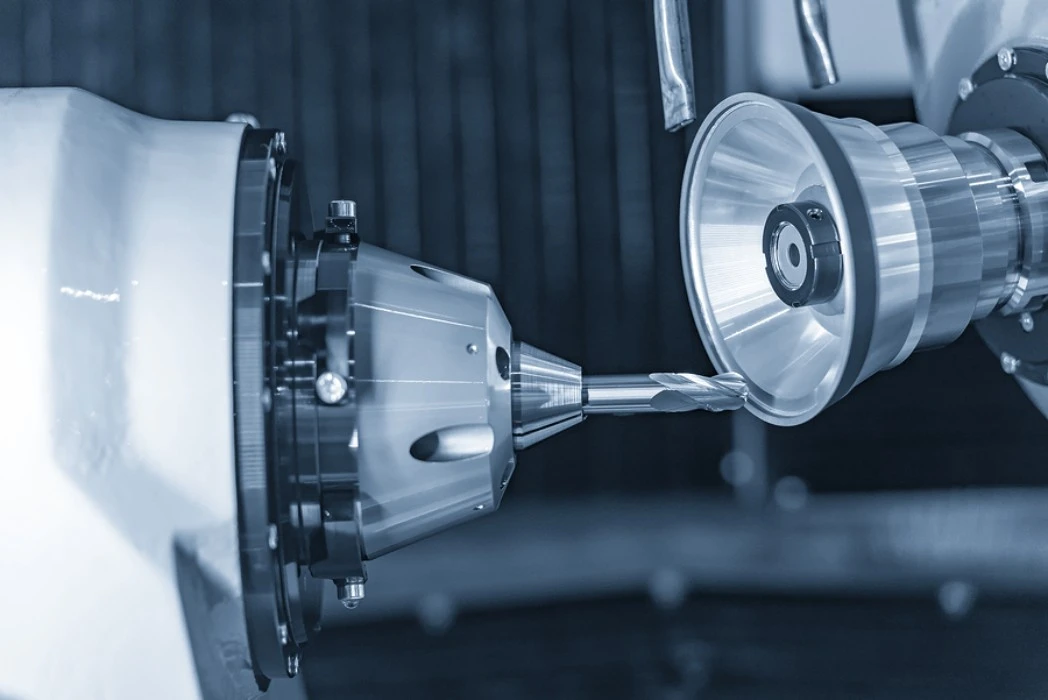

Cutting-Edge Machining Technologies

Today, aerospace parts machining incorporates state-of-the-art technologies such as 5-axis CNC machining, high-speed machining (HSM), and electrical discharge machining (EDM). These advanced techniques enable the production of complex, lightweight components with exceptional surface finishes. Additionally, the integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) software has further enhanced the capabilities of aerospace machining, allowing for seamless transition from design to production.

Critical Factors in Aerospace Parts Machining

Material Selection and Characteristics

The choice of materials in aerospace parts machining is paramount to ensuring the performance and longevity of aircraft components. Aerospace-grade materials such as titanium alloys, high-strength aluminum, and superalloys are commonly used due to their exceptional strength-to-weight ratios and resistance to extreme temperatures and corrosion. These materials present unique machining challenges, requiring specialized cutting tools and techniques to achieve the desired results.

Precision and Tolerance Requirements

Aerospace parts demand extremely tight tolerances, often measured in microns. This level of precision is essential for ensuring proper fit, function, and safety of aircraft components. Achieving and maintaining such tight tolerances requires advanced machining equipment, rigorous quality control processes, and highly skilled operators. The ability to consistently meet these exacting standards is a hallmark of top-tier aerospace machining providers.

Quality Control and Certification

The aerospace industry is subject to stringent quality control standards and regulatory requirements. Aerospace parts manufacturers must adhere to certifications such as AS9100 and NADCAP to ensure compliance with industry standards. Rigorous inspection processes, including non-destructive testing (NDT) and dimensional verification, are employed to validate the quality and integrity of machined components. This unwavering commitment to quality is essential for maintaining the safety and reliability of aircraft systems.

Impact of Aerospace Parts Machining on Industry Standards

Enhancing Aircraft Performance and Efficiency

Precision aerospace parts machining plays a vital role in optimizing the performance and efficiency of modern aircraft. By producing components with exact geometries and high-quality surface finishes, these processes reduce aerodynamic drag and improve fuel efficiency. Machined parts, from turbine blades to structural supports, contribute to smoother airflow and lower energy consumption. Enhanced efficiency not only translates into operational cost savings for airlines but also supports environmental sustainability by reducing emissions. The meticulous engineering of each component ensures that aircraft operate at peak performance under varying flight conditions.

Advancing Safety and Reliability

The rigorous standards in aerospace parts machining are essential for ensuring aircraft safety and system reliability. Precision manufacturing produces components with consistent dimensions, tolerance accuracy, and material integrity, minimizing the risk of mechanical failure. High-quality machining reduces variability between parts, supporting the seamless integration of complex assemblies and critical systems. This focus on exacting standards strengthens the overall structural and operational reliability of aircraft, enhancing passenger and crew safety. Aerospace machining thereby serves as a foundational element in maintaining trust and compliance within the aviation industry.

Driving Innovation in Aerospace Design

Innovations in aerospace parts machining have empowered engineers and designers to explore advanced concepts in aircraft development. Precision machining enables the creation of intricate, lightweight structures and the integration of high-performance materials, supporting the design of more efficient and capable aircraft. From commercial airliners to military jets, machining technology allows for complex geometries that were previously unattainable. This capability drives technological progress, enabling manufacturers to meet performance, safety, and environmental goals. Continuous advancements in machining expand possibilities for future aerospace designs, fostering innovation across the industry and pushing aviation engineering to new heights.

Conclusion

Aerospace parts machining stands as a cornerstone of the aviation and space industries, playing a vital role in upholding and advancing industry standards. Through the use of cutting-edge technologies, rigorous quality control processes, and a commitment to precision, aerospace machining contributes significantly to the safety, efficiency, and innovation of modern aircraft. As the industry continues to evolve, the importance of high-quality, precision-machined components will only grow, driving further advancements in manufacturing techniques and materials science.

FAQs

What materials are commonly used in aerospace parts machining?

Aerospace-grade materials such as titanium alloys, high-strength aluminum, and superalloys are frequently used due to their excellent strength-to-weight ratios and resistance to extreme conditions.

How does aerospace parts machining contribute to aircraft safety?

Precision machining ensures components meet strict tolerances and quality standards, reducing the risk of part failure and enhancing overall system reliability.

What certifications are important for aerospace parts manufacturers?

Key certifications include AS9100 for quality management systems and NADCAP for special processes in the aerospace industry.

Expert Aerospace Parts Machining Solutions | BOEN

At BOEN Rapid, we specialize in high-precision aerospace parts machining, offering unparalleled expertise in CNC machining, injection molding, and advanced manufacturing techniques. Our state-of-the-art facilities and skilled engineers ensure aerospace components meet the most stringent industry standards. With rapid prototyping capabilities and global shipping, we're your trusted partner for aerospace manufacturing excellence. Contact us at contact@boenrapid.com to elevate your aerospace projects with our cutting-edge solutions.

References

Smith, J. (2021). Advances in Aerospace Machining Technologies. Journal of Aerospace Engineering, 34(2), 145-160.

Johnson, R., & Brown, T. (2020). Quality Control in Aerospace Manufacturing: A Comprehensive Guide. Aerospace Quality Press.

Thompson, L. (2022). The Impact of Precision Machining on Aircraft Efficiency. International Journal of Aviation Technology, 15(3), 278-295.

Davis, M., & Wilson, K. (2019). Materials Science in Aerospace Applications. Advanced Materials Today, 8(4), 412-430.

Anderson, P. (2023). Emerging Trends in Aerospace Parts Manufacturing. Aviation Week & Space Technology, 185(6), 52-58.

Lee, S., & Chang, H. (2020). Regulatory Frameworks and Certification Processes in the Aerospace Industry. Aerospace Compliance Review, 12(1), 75-92.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.