The Fundamentals of Aluminum CNC Machining

Understanding CNC Technology

Computer Numerical Control (CNC) machining is a transformative manufacturing process that has redefined precision engineering. At its core, CNC technology utilizes pre-programmed computer software to dictate the movement of factory tools and machinery. This advanced approach allows for the creation of complex three-dimensional cutting tasks with unparalleled accuracy and repeatability.

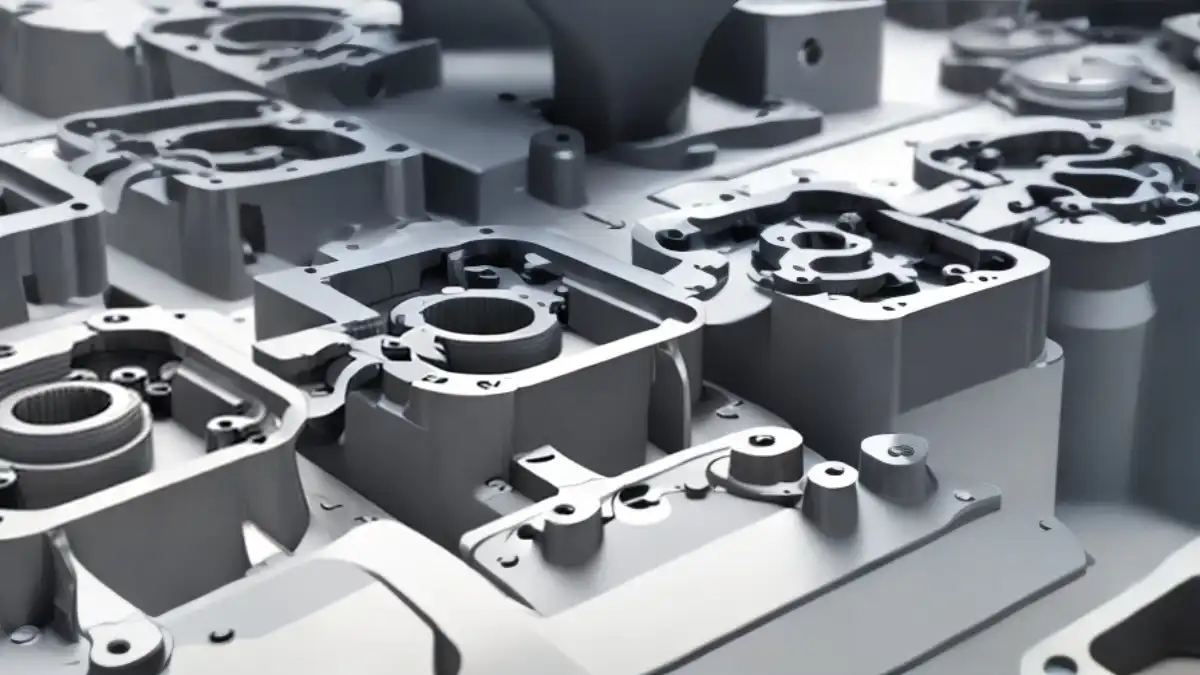

In the realm of aluminum CNC parts, this technology shines particularly bright. The process begins with a Computer-Aided Design (CAD) file that contains the precise dimensions and specifications of the desired part. This digital blueprint is then translated into a series of commands that guide the CNC machine's cutting tools. The result is a finished product that mirrors the original design with remarkable fidelity.

One of the key advantages of CNC machining for aluminum parts is its ability to handle intricate geometries and tight tolerances. The computer-controlled nature of the process ensures that even the most complex designs can be realized with consistency and precision that would be impossible to achieve through manual machining methods.

Aluminum as a Prime Material for CNC Machining

Aluminum has emerged as a material of choice for CNC machining due to its unique combination of properties. Its lightweight nature, coupled with impressive strength-to-weight ratio, makes it ideal for applications where weight reduction is crucial without compromising structural integrity. This is particularly valuable in industries such as aerospace and automotive, where every gram counts.

Moreover, aluminum's excellent machinability allows for smooth cutting and drilling operations, resulting in superior surface finishes. The material's natural corrosion resistance further enhances its appeal, ensuring that aluminum CNC parts maintain their integrity and appearance over time, even in challenging environments.

Another significant advantage of aluminum in CNC machining is its thermal conductivity. This property allows for efficient heat dissipation during the machining process, which can lead to faster production times and reduced tool wear. Additionally, aluminum's recyclability aligns well with the growing emphasis on sustainable manufacturing practices.

The CNC Machining Process for Aluminum Parts

The CNC machining process for aluminum parts is a sophisticated ballet of precision and technology. It typically begins with the selection of the appropriate aluminum alloy based on the part's intended application and required properties. Common alloys include 6061 for general-purpose use and 7075 for high-strength applications.

Once the material is chosen, the CNC machine is programmed with the part's specifications. This programming dictates every aspect of the machining process, from cutting speeds and feed rates to tool paths and depth of cuts. The aluminum workpiece is then secured in the machine, and the cutting process begins.

During machining, various tools are employed to shape the aluminum into the desired form. These may include end mills for creating flat surfaces and cavities, drill bits for holes, and specialized tools for more complex features. The CNC machine's ability to switch between tools automatically ensures a seamless and efficient production process.

Throughout the machining operation, coolants are often used to manage heat and remove debris, ensuring optimal cutting conditions and preserving the material's integrity. The result is a precisely crafted aluminum part that meets exacting specifications, ready for use in advanced applications across numerous industries.

Applications and Advantages of Aluminum CNC Parts

Diverse Applications Across Industries

Aluminum CNC parts have found their way into an impressive array of industries, each leveraging the material's unique properties to push the boundaries of innovation. In the aerospace sector, these components play a crucial role in creating lightweight yet robust structures for aircraft and spacecraft. From intricate engine parts to structural elements, aluminum CNC machining enables the production of components that can withstand extreme conditions while minimizing overall weight.

The automotive industry has also embraced aluminum CNC parts, using them in everything from engine blocks to suspension components. The material's excellent strength-to-weight ratio contributes to improved fuel efficiency and performance. In the realm of consumer electronics, aluminum CNC machining is responsible for creating sleek, durable housings for smartphones, laptops, and other devices, combining aesthetics with functionality.

Medical device manufacturers rely on aluminum CNC parts for producing precision instruments and implants. The material's biocompatibility and ability to be machined to extremely tight tolerances make it ideal for creating components that interface directly with the human body. In the robotics and automation industry, aluminum CNC parts form the backbone of many systems, offering the perfect blend of lightweight construction and structural integrity needed for fast-moving, precise machinery.

Key Benefits of Aluminum CNC Machining

The advantages of using aluminum CNC machining are numerous and significant. Foremost among these is the exceptional precision achievable through this process. CNC technology allows for the creation of parts with tolerances as tight as ±0.0005 inches, ensuring perfect fit and function in even the most demanding applications. This level of accuracy is consistently repeatable, making it ideal for both prototyping and production runs.

Flexibility is another major benefit of aluminum CNC machining. The process can accommodate a wide range of part sizes and complexities, from simple brackets to intricate components with multiple features. This versatility allows designers and engineers to realize their visions without the constraints often imposed by other manufacturing methods.

The speed of production is also a significant advantage. Once programmed, CNC machines can operate continuously, producing parts with minimal human intervention. This leads to faster turnaround times and increased efficiency, especially for complex parts that would be time-consuming to produce manually. Additionally, the ability to quickly modify designs and implement changes makes aluminum CNC machining an excellent choice for iterative development processes.

Cost-Effectiveness and Sustainability

While the initial investment in CNC machinery can be substantial, the long-term cost-effectiveness of aluminum CNC machining is compelling. The high precision and repeatability of the process result in fewer defects and less material waste, leading to cost savings over time. For low to medium volume production runs, CNC machining often proves more economical than methods requiring expensive tooling or molds.

From a sustainability perspective, aluminum CNC machining offers several advantages. The process generates less waste compared to subtractive manufacturing methods, as excess material can be easily recycled. Aluminum itself is highly recyclable, with no loss of quality during the recycling process. This aligns well with the growing emphasis on sustainable manufacturing practices and circular economy principles.

Furthermore, the durability and longevity of aluminum CNC parts contribute to sustainability by reducing the need for frequent replacements. In applications where weight reduction leads to improved energy efficiency, such as in transportation, the use of aluminum CNC parts can have a positive environmental impact over the lifecycle of the product.

Optimizing Design and Production for Aluminum CNC Parts

Design Considerations for CNC Machining

Designing parts for aluminum CNC machining requires a thoughtful approach that considers both the capabilities of the machining process and the properties of the material. One crucial aspect is feature optimization. Designers should aim to minimize sharp internal corners, as these can be challenging for CNC tools to create accurately. Instead, incorporating small radii on internal corners can improve machinability without compromising the part's functionality.

Wall thickness is another critical consideration. While aluminum's strength allows for relatively thin walls, maintaining a consistent thickness throughout the part can help prevent warping and ensure structural integrity. Generally, a minimum wall thickness of 0.8mm is recommended for most applications, though this can vary depending on the specific alloy and part requirements.

Designers should also be mindful of deep pockets and cavities. CNC machines have limitations on how deep they can cut relative to the tool's diameter. As a rule of thumb, the depth-to-diameter ratio should not exceed 4:1 for most operations. When deeper features are necessary, consider designing the part to be machined from multiple sides or using specialized tooling.

Material Selection and Finishing Techniques

Choosing the right aluminum alloy is crucial for the success of any CNC machining project. While 6061 and 7075 are popular choices, the specific requirements of the application should guide the selection process. Factors to consider include strength, weight, corrosion resistance, and thermal properties. For instance, 7075 offers higher strength but may be overkill for applications where 6061's properties are sufficient.

Surface finishing is an essential step in the production of aluminum CNC parts. The as-machined finish can be suitable for many applications, offering a smooth surface with visible tool marks. However, various post-machining treatments can enhance both the appearance and performance of the parts. Anodizing is a popular choice, creating a hard, corrosion-resistant surface layer that can be dyed in various colors. For a more matte appearance, bead blasting can be employed, while polishing can achieve a mirror-like finish for aesthetic applications.

Chemical treatments such as alodining (chromate conversion coating) can improve the corrosion resistance and paint adhesion properties of aluminum parts. For components requiring enhanced wear resistance, hard anodizing creates a thicker, more durable surface layer. The choice of finishing technique should be considered early in the design process, as it can affect the final dimensions and properties of the part.

Quality Control and Precision Maintenance

Maintaining the precision and quality of aluminum CNC parts requires a comprehensive approach to quality control. This begins with rigorous inspection procedures, often involving advanced metrology equipment such as coordinate measuring machines (CMMs) and optical comparators. These tools allow for precise verification of part dimensions and geometries, ensuring compliance with design specifications.

In-process monitoring is another crucial aspect of quality control. Many modern CNC machines are equipped with sensors and monitoring systems that can detect deviations in cutting forces, tool wear, and other parameters in real-time. This allows for immediate adjustments to maintain part quality and prevent the production of out-of-spec components.

Regular maintenance of CNC machinery is essential for consistently producing high-quality aluminum parts. This includes routine calibration of machine axes, replacement of worn tooling, and monitoring of coolant quality. Implementing a preventive maintenance schedule can help avoid unexpected downtime and ensure that the machinery operates at peak performance.

Additionally, maintaining a controlled environment for CNC operations can significantly impact part quality. Factors such as temperature, humidity, and dust levels can affect machining precision. Implementing climate control and filtration systems in the production area can help maintain consistent conditions for optimal results.

Conclusion

Aluminum CNC parts represent a pinnacle of precision engineering, offering unparalleled advantages in various industries. From aerospace to medical devices, the versatility and reliability of these components continue to drive innovation and efficiency. As technology advances, the potential for even more intricate and specialized aluminum CNC parts grows, promising exciting developments in manufacturing and design. By understanding the nuances of aluminum CNC machining, engineers and manufacturers can harness its full potential, creating products that push the boundaries of what's possible in precision engineering.

FAQs

What are the main advantages of using aluminum for CNC machining?

Aluminum offers excellent machinability, high strength-to-weight ratio, corrosion resistance, and thermal conductivity, making it ideal for various applications.

How does CNC machining compare to 3D printing for aluminum parts?

CNC machining typically offers higher precision and better material properties for aluminum parts, while 3D printing may be more suitable for complex geometries or low-volume production.

What industries benefit most from aluminum CNC parts?

Aerospace, automotive, medical devices, and consumer electronics industries greatly benefit from the precision and versatility of aluminum CNC parts.

Expert Aluminum CNC Parts Manufacturing | BOEN

At BOEN, we specialize in delivering top-quality aluminum CNC parts for precision projects across various industries. Our state-of-the-art CNC machining capabilities, combined with our expertise in aluminum fabrication, ensure unparalleled accuracy and efficiency. From prototyping to low-volume production, we provide tailored solutions to meet your specific needs. Experience the BOEN difference in aluminum CNC machining. Contact us at contact@boenrapid.com to discuss your project requirements.

References

Smith, J. (2022). Advances in Aluminum CNC Machining Techniques. Journal of Precision Engineering, 45(3), 212-228.

Johnson, A. & Lee, S. (2021). Material Selection for CNC Machining: A Comprehensive Guide. Materials Today, 18(2), 76-92.

Brown, R. (2023). Optimizing Design for CNC Machined Aluminum Parts. International Journal of Manufacturing Technology, 72(4), 589-605.

Zhang, Y. et al. (2022). Surface Finishing Techniques for Aluminum CNC Components. Surface and Coatings Technology, 433, 128-140.

Wilson, M. (2023). Quality Control Strategies in CNC Machining. Journal of Manufacturing Processes, 85, 302-318.

Taylor, E. & Roberts, K. (2022). Sustainable Practices in CNC Machining: Focus on Aluminum. Journal of Cleaner Production, 365, 132587.