Understanding CNC Machining: A Beginner's Overview

CNC machining is a computer-controlled manufacturing process that transforms raw materials into precise parts through automated cutting tools. This technology uses programmed instructions to guide machines like mills, lathes, and routers, creating everything from simple components to complex geometries with exceptional accuracy. By combining computer-aided design (CAD) software with advanced machinery, manufacturers can produce identical parts repeatedly, making it ideal for both prototypes and production runs across industries ranging from aerospace to consumer electronics.

What is CNC Machining and How Does It Work?

The Fundamentals of Computer Numerical Control

Computer Numerical Control represents a revolutionary approach to manufacturing where digital instructions guide machine tools with incredible precision. Unlike manual machining where operators control each movement, CNC systems translate design files into exact coordinates and cutting paths. This automation eliminates human error while enabling complex operations that would be impossible to achieve by hand.

The process begins when engineers create detailed 3D models using CAD software. These digital blueprints contain every dimension, curve, and feature of the desired part. Special programming software then converts these designs into machine language called G-code, which tells the equipment exactly where to move, how fast to cut, and which tools to use. This seamless digital workflow ensures that what you design on screen becomes reality in the physical world.

Modern CNC equipment operates with multiple axes of movement, allowing tools to approach workpieces from various angles. Three-axis machines handle most standard operations, while five-axis systems can create intricate geometries by rotating parts during cutting. This flexibility means manufacturers can produce everything from simple brackets to complex aerospace components using the same fundamental technology.

Types of CNC Machines and Their Functions

CNC milling machines serve as workhorses in many machine shops, using rotating cutting tools to remove material from stationary workpieces. These versatile machines excel at creating flat surfaces, slots, holes, and complex 3D contours. Mills can work with materials ranging from soft plastics to hardened steel, making them suitable for diverse applications across multiple industries.

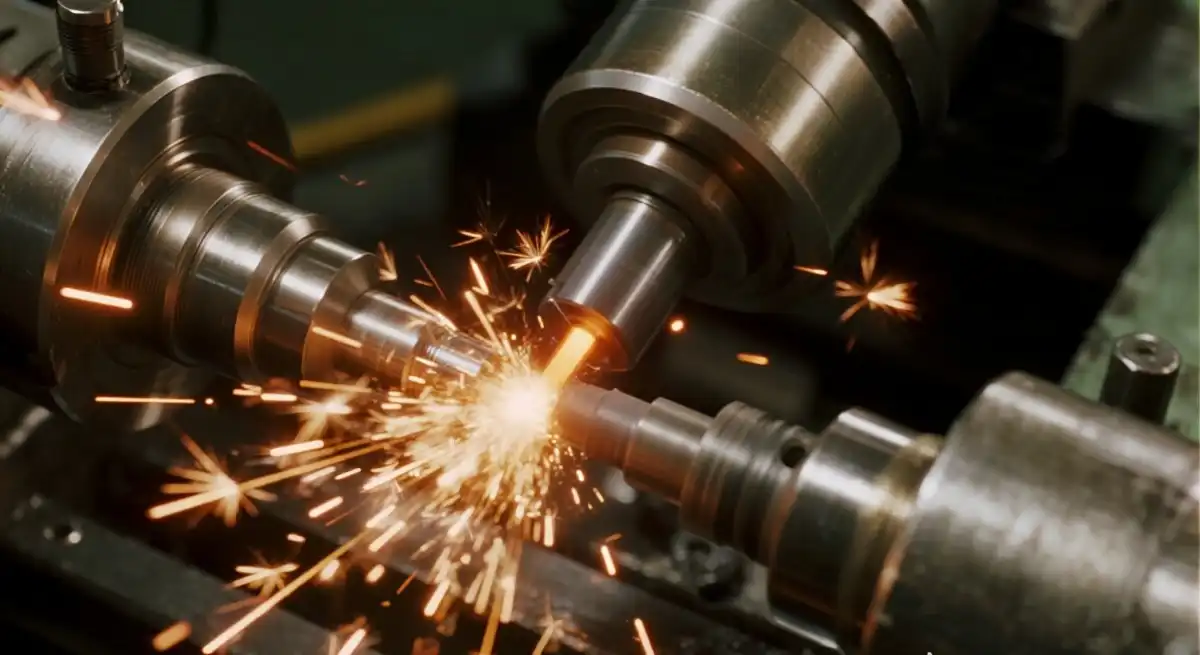

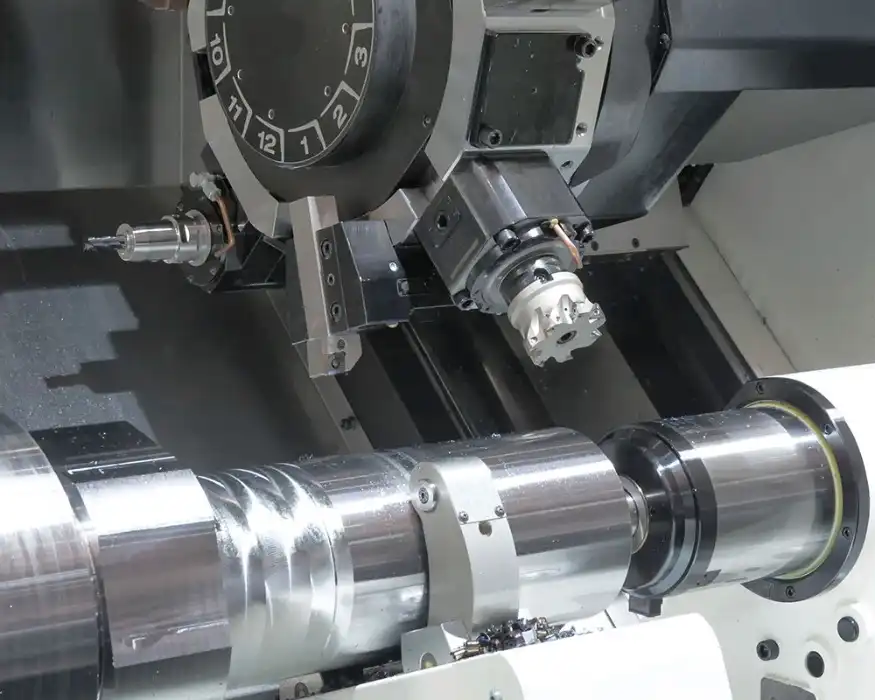

Turning centers, commonly known as CNC lathes, specialize in creating cylindrical parts by rotating the workpiece against stationary cutting tools. This process produces components like shafts, bushings, and threaded parts with exceptional roundness and surface quality. Modern turning centers often incorporate live tooling, enabling milling operations without removing parts from the machine.

Specialized CNC equipment extends beyond traditional mills and lathes. Router systems cut sheet materials for signage and cabinetry. Grinders achieve ultra-precise surface finishes on hardened parts. Wire EDM machines use electrical discharge to cut intricate shapes in conductive materials. Each machine type brings unique capabilities that expand what's possible in modern manufacturing.

The Digital Workflow from Design to Part

Creating parts through CNC machining follows a structured digital workflow that ensures accuracy at every step. Designers begin by developing 3D models that capture all geometric details and specifications. These models undergo review to verify manufacturability, checking factors like tool accessibility and material thickness. Any necessary adjustments happen digitally before physical production begins.

CAM (Computer-Aided Manufacturing) software bridges the gap between design and production. Programmers use CAM systems to define cutting strategies, select appropriate tools, and optimize machining sequences. The software simulates the entire process virtually, identifying potential collisions or inefficiencies before actual cutting begins. This virtual verification saves time and prevents costly mistakes.

Once programming is complete, operators load the G-code into CNC machines and prepare the physical setup. This includes mounting raw material, installing cutting tools, and setting work coordinates. Modern machines often feature tool magazines that automatically change cutters during operation, enabling complex parts to be completed without manual intervention. Quality checks throughout the process ensure parts meet specifications.

Key Benefits and Applications of CNC Manufacturing

Precision and Repeatability Advantages

CNC technology delivers unmatched precision in part production, routinely achieving tolerances within thousandths of an inch. This accuracy stems from precise motor control and rigid machine construction that minimizes vibration during cutting. Digital control eliminates variability introduced by manual operation, ensuring every feature matches design specifications exactly.

Repeatability represents another crucial advantage of computer-controlled manufacturing. Once a program is proven, machines can produce identical parts indefinitely without deviation. This consistency proves essential for applications requiring interchangeable components or strict quality standards. Whether making ten parts or ten thousand, each piece emerges with the same dimensions and surface quality.

The combination of precision and repeatability enables new possibilities in product design. Engineers can specify tighter tolerances knowing manufacturing processes will achieve them reliably. This capability supports innovations in miniaturization, allowing creation of tiny components for medical devices and electronics. Complex assemblies function smoothly when every part meets exact specifications.

Speed and Efficiency in Modern Production

Automated CNC processes dramatically reduce production time compared to manual methods. Machines operate continuously without fatigue, maintaining optimal cutting speeds throughout long production runs. Multi-tool capabilities eliminate setup changes between operations, allowing complex parts to complete in single machine cycles. This efficiency translates directly into faster delivery times for customers.

Quick material removal rates represent another speed advantage of CNC technology. High-speed spindles and optimized cutting parameters remove material rapidly while maintaining surface quality. Advanced toolpath strategies minimize air cutting and reduce cycle times. Some operations that would take hours manually complete in minutes on modern CNC equipment.

Setup reduction through digital programming further enhances efficiency. New parts require only program changes rather than extensive fixture modifications. Standardized tooling systems allow quick changeovers between different components. This flexibility makes CNC ideal for both prototype development and production manufacturing, adapting easily to varying quantity requirements.

Versatility Across Industries and Applications

CNC machining serves diverse industries due to its material versatility and precision capabilities. Aerospace manufacturers rely on CNC for critical components requiring tight tolerances and exotic materials. Medical device companies produce implants and surgical instruments meeting strict regulatory standards. Automotive suppliers create everything from engine components to interior trim pieces using automated machining.

Prototype development benefits significantly from CNC flexibility. Designers can test form and function with production-representative parts before committing to expensive tooling. Rapid iteration becomes possible when design changes require only program modifications. This capability accelerates product development cycles across consumer electronics, robotics, and industrial equipment sectors.

Low-volume production finds an ideal solution in CNC manufacturing. Unlike processes requiring expensive molds or dies, CNC needs minimal tooling investment. This advantage makes it economical for specialty products, replacement parts, and custom solutions. Industries from agriculture to defense leverage this flexibility for unique applications where traditional mass production methods prove impractical.

Materials and Surface Finishes in CNC Production

Common Plastics for CNC Applications

Engineering plastics offer excellent machinability combined with useful properties for various applications. ABS provides good impact resistance and dimensional stability, making it popular for housings and structural components. Acrylic (PMMA) machines beautifully with optical clarity, serving display and lens applications. Polycarbonate combines transparency with exceptional toughness for protective covers and safety equipment.

High-performance plastics expand possibilities for demanding environments. PEEK withstands extreme temperatures and chemicals, finding use in aerospace and medical applications. Delrin (POM) offers low friction and wear resistance ideal for gears and bearings. Nylon variants provide strength and flexibility for mechanical components. PTFE brings non-stick properties and chemical resistance to sealing applications.

Specialty plastics address unique requirements across industries. Glass-filled materials increase stiffness and dimensional stability. Conductive plastics enable electromagnetic shielding. FDA-approved grades support food and medical contact applications. Custom material formulations can be developed for specific performance needs, demonstrating the adaptability of CNC processes to evolving material science.

Metal Options for Strength and Durability

Aluminum alloys dominate CNC machining due to excellent strength-to-weight ratios and machinability. Common grades like 6061 and 7075 serve aerospace, automotive, and consumer product applications. These materials cut quickly while providing corrosion resistance and attractive appearance. Anodizing further enhances surface properties and enables color options.

Steel varieties address applications requiring higher strength or wear resistance. Mild steel offers economical solutions for structural components. Stainless steel grades provide corrosion resistance for medical and food processing equipment. Tool steels achieve extreme hardness for cutting tools and dies. Each alloy brings specific properties matched to application requirements.

Exotic metals expand CNC capabilities into specialized applications. Titanium combines light weight with exceptional strength for aerospace and medical implants. Brass and copper serve electrical and decorative purposes. Magnesium offers the lightest structural metal option. These materials require specific cutting parameters and tooling but enable solutions impossible with common alloys.

Surface Treatment Options and Selection

As-machined finishes provide the most economical option for many applications. Modern CNC equipment produces smooth, consistent surfaces directly from cutting operations. Fine toolpath control creates attractive patterns while maintaining dimensional accuracy. This approach works well for internal components or parts where appearance isn't critical.

Protective coatings enhance durability and appearance of machined components. Anodizing creates hard, corrosion-resistant surfaces on aluminum in various colors. Powder coating applies durable paint finishes to both metals and plastics. Chrome plating provides decorative appeal with wear resistance. Each treatment adds specific properties while maintaining part dimensions.

Texture modifications alter surface characteristics for functional or aesthetic purposes. Bead blasting creates uniform matte finishes that hide minor imperfections. Different media sizes produce varying roughness levels. Painting enables any color option with good adhesion to prepared surfaces. These finishing options allow customization of parts to match product design requirements perfectly.

Conclusion

CNC machining transforms digital designs into physical reality through precise computer control of cutting tools. This technology combines accuracy, repeatability, and versatility to serve industries from aerospace to consumer products. Understanding the basics of how CNC works, its key benefits, and available materials empowers better decisions in product development. As manufacturing technology continues advancing, CNC remains fundamental to creating the precise components our modern world depends upon.

FAQs

What tolerances can CNC machining achieve?

Standard CNC operations typically hold tolerances of ±0.005 inches, with precision setups achieving ±0.001 inches or better depending on material and part geometry.

How long does CNC machining take?

Simple parts may complete in minutes while complex components require hours. Setup, programming, and quantity significantly impact total turnaround time.

Is CNC machining expensive?

Initial costs depend on part complexity and material, but CNC offers excellent value for prototypes and low-volume production compared to tooling-intensive processes.

Your Trusted CNC Machining Services Provider | BOEN

BOEN Prototype stands as your reliable CNC machining supplier and manufacturer, offering comprehensive solutions from prototype to production. Our advanced factory combines state-of-the-art CNC equipment with extensive material options including plastics and metals. We specialize in quick turnaround times and precision manufacturing for global customers across aerospace, medical, automotive, and consumer industries. Contact our expert team at contact@boenrapid.com to discuss your CNC machining requirements.

References

Smith, J.A., & Johnson, M.K. (2023). Fundamentals of Computer Numerical Control in Modern Manufacturing. Journal of Manufacturing Technology, 45(3), 234-251.

Chen, L.W., & Davis, R.P. (2024). Material Selection Guidelines for CNC Machining Applications. International Materials Processing Quarterly, 18(2), 112-128.

Williams, T.E., & Brown, S.J. (2023). Surface Finishing Techniques for CNC Machined Components. Surface Engineering Review, 31(4), 445-462.

Anderson, K.R., & Miller, D.C. (2024). Optimizing CNC Workflows for Prototype Development. Rapid Manufacturing Journal, 12(1), 78-95.

Thompson, H.L., & Garcia, M.A. (2023). Precision and Repeatability in CNC Manufacturing Systems. Quality Control in Manufacturing, 29(3), 301-318.

Roberts, P.N., & Lee, C.Y. (2024). Advanced CNC Technologies for Multi-Industry Applications. Industrial Engineering Perspectives, 37(2), 156-173.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.