Cost Management and Efficiency in Small-Batch Production

Balancing Overhead Costs

One of the most critical challenges in low-volume manufacturing is effectively balancing overhead costs. Since smaller production runs spread fixed expenses across fewer units, the per-unit cost can increase significantly. To maintain competitiveness, manufacturers must explore lean manufacturing principles, improve workflow efficiency, and leverage digital tools for cost tracking. Additionally, using co-working facilities, subcontracting non-core activities, or adopting energy-efficient equipment can reduce expenses. These strategies enable small-batch manufacturers to control overhead while preserving consistent product quality and operational reliability.

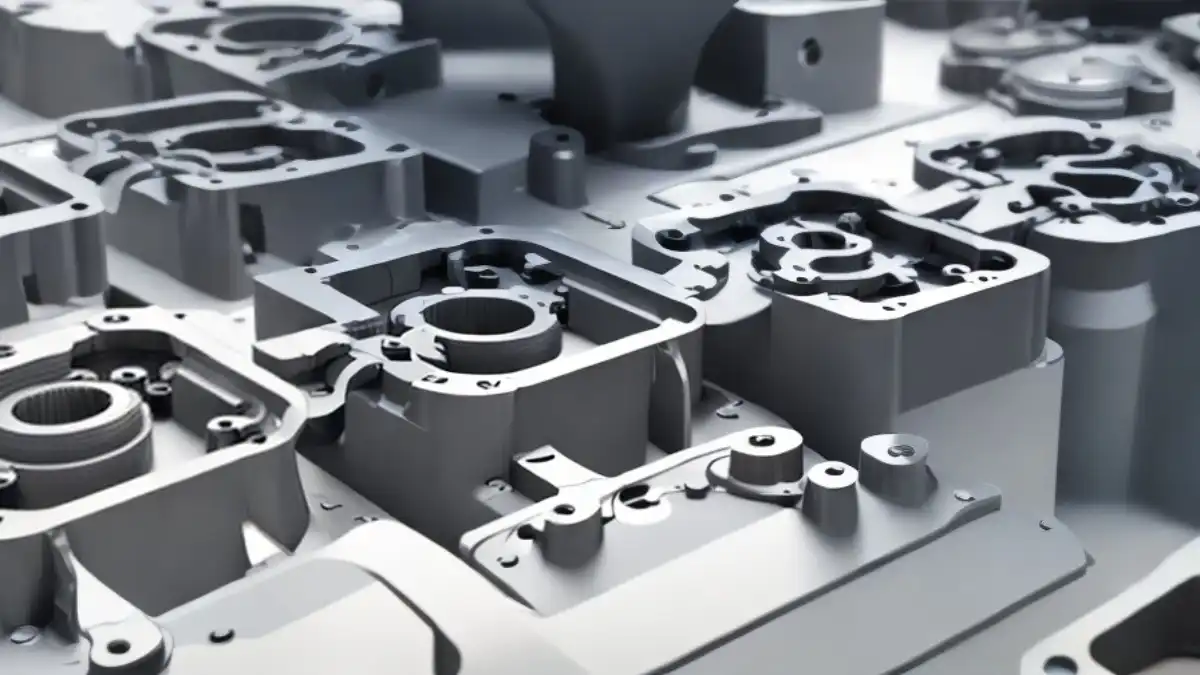

Tooling and Setup Considerations

Tooling costs often represent a significant barrier in low-volume manufacturing. Traditional high-volume molds or dies are rarely economical for limited runs. To address this, manufacturers can use rapid tooling, additive manufacturing, or modular mold systems that lower initial investments while supporting repeatable quality. Quick-change tooling solutions and reconfigurable fixtures also reduce setup times, which are disproportionately high in small-batch production. Careful evaluation of tooling options ensures cost-effectiveness without sacrificing accuracy, making it possible to achieve profitability even in low-volume scenarios.

Optimizing Production Processes

Efficiency in small-batch manufacturing depends heavily on agile and flexible production processes. Unlike large-scale operations, small runs require manufacturers to reach peak efficiency quickly. This can be achieved through cross-trained workers who handle multiple roles, flexible machinery that adapts to various product types, and advanced software for real-time scheduling and resource allocation. Minimizing downtime between orders and improving changeover speed are vital. By integrating these strategies, small-batch producers can maintain productivity, reduce waste, and deliver high-quality parts within tight timelines.

Quality Control and Consistency Challenges

Maintaining Quality Standards

Ensuring consistent quality across small production batches can be challenging. With fewer units produced, there's less opportunity to refine processes through repetition. Manufacturers must implement robust quality control measures from the outset, including thorough inspection protocols and statistical process control techniques adapted for low-volume scenarios. Investing in advanced measurement and inspection equipment can help maintain high-quality standards across limited production runs.

Material Variability Management

Low-volume production often involves working with smaller quantities of materials, which can lead to increased variability between batches. This variability can affect product consistency and quality. Manufacturers need to establish strong relationships with suppliers to ensure consistent material properties and implement rigorous incoming material inspection processes. Additionally, they may need to develop adaptive manufacturing techniques that can compensate for minor material variations without compromising product integrity.

Documentation and Traceability

Maintaining comprehensive documentation and traceability is crucial in low-volume manufacturing, especially for industries with strict regulatory requirements. With smaller batches, each unit may need more detailed tracking and documentation. Implementing robust enterprise resource planning (ERP) systems and product lifecycle management (PLM) tools can help manage the increased complexity of tracking materials, processes, and quality data for each production run.

Supply Chain and Inventory Management Issues

Supplier Relationships and Minimum Order Quantities

Low-volume manufacturers often struggle with meeting minimum order quantities (MOQs) set by suppliers, which are typically geared towards larger production volumes. This can lead to excess inventory or difficulty in sourcing materials. Building strong relationships with suppliers who understand the unique needs of low-volume production is essential. Manufacturers may need to negotiate flexible purchasing agreements, explore alternative sourcing strategies, or consider working with specialized suppliers who cater to small-batch production needs.

Inventory Control and Storage

Managing inventory for low-volume manufacturing production requires a delicate balance. Overstocking can tie up capital and increase storage costs, while understocking can lead to production delays. Implementing just-in-time (JIT) inventory systems can be challenging with smaller, less predictable orders. Manufacturers need to develop accurate demand forecasting methods, consider consignment inventory arrangements with suppliers, and optimize storage solutions to manage inventory effectively without incurring excessive costs.

Lead Time Management

Low-volume orders often come with expectations of shorter lead times, which can be challenging to meet consistently. Managing lead times requires careful coordination of supply chain activities, production scheduling, and capacity planning. Manufacturers may need to invest in advanced planning and scheduling software, develop modular product designs that allow for faster customization, and establish flexible production cells that can quickly adapt to different product requirements.

Conclusion

Low-volume manufacturing presents unique challenges that require innovative solutions and strategic planning. By focusing on cost-effective production methods, maintaining rigorous quality control, and optimizing supply chain management, manufacturers can successfully navigate these challenges. Embracing flexible manufacturing technologies, fostering strong supplier relationships, and implementing robust process control systems are key to thriving in the low-volume production landscape. As markets continue to demand more customized and specialized products, mastering the art of efficient small-batch manufacturing will become increasingly important for businesses across various industries.

FAQs

What is considered low-volume manufacturing?

Low-volume manufacturing typically refers to production runs of 1,000 units or less per year, though this can vary by industry.

How does low-volume manufacturing differ from high-volume production?

Low-volume manufacturing often involves more specialized processes, higher per-unit costs, and greater flexibility in design changes compared to high-volume production.

What industries commonly use low-volume manufacturing?

Industries such as aerospace, medical devices, specialty automotive, and custom electronics frequently utilize low-volume manufacturing techniques.

Partner with BOEN for Your Low-Volume Manufacturing Needs

At BOEN, we specialize in overcoming the challenges of low-volume manufacturing. Our expertise in rapid prototyping and small-batch production allows us to deliver high-quality parts efficiently and cost-effectively. Whether you need CNC machining, injection molding, or 3D printing services, our state-of-the-art facilities and experienced team are ready to meet your unique production requirements. As your trusted manufacturing partner and supplier, we ensure top-notch quality and timely delivery for all your low-volume projects. Contact us at contact@boenrapid.com to discuss how we can support your manufacturing needs.

References

Smith, J. (2022). "Navigating the Complexities of Low-Volume Manufacturing." Journal of Manufacturing Technology.

Johnson, A. & Brown, L. (2021). "Quality Control Strategies for Small Batch Production." International Journal of Quality Management.

Lee, S. (2023). "Supply Chain Optimization in Low-Volume, High-Mix Environments." Supply Chain Management Review.

Wilson, R. (2022). "Cost-Effective Tooling Solutions for Low-Volume Manufacturing." Advanced Materials & Processes.

Garcia, M. (2023). "Lean Manufacturing Principles Applied to Small-Scale Production." Lean Enterprise Institute Publications.

Thompson, K. (2021). "Inventory Management Techniques for Low-Volume Manufacturers." Operations Management Journal.