Scaling Challenges in Test Batch Production

Adapting Production Processes

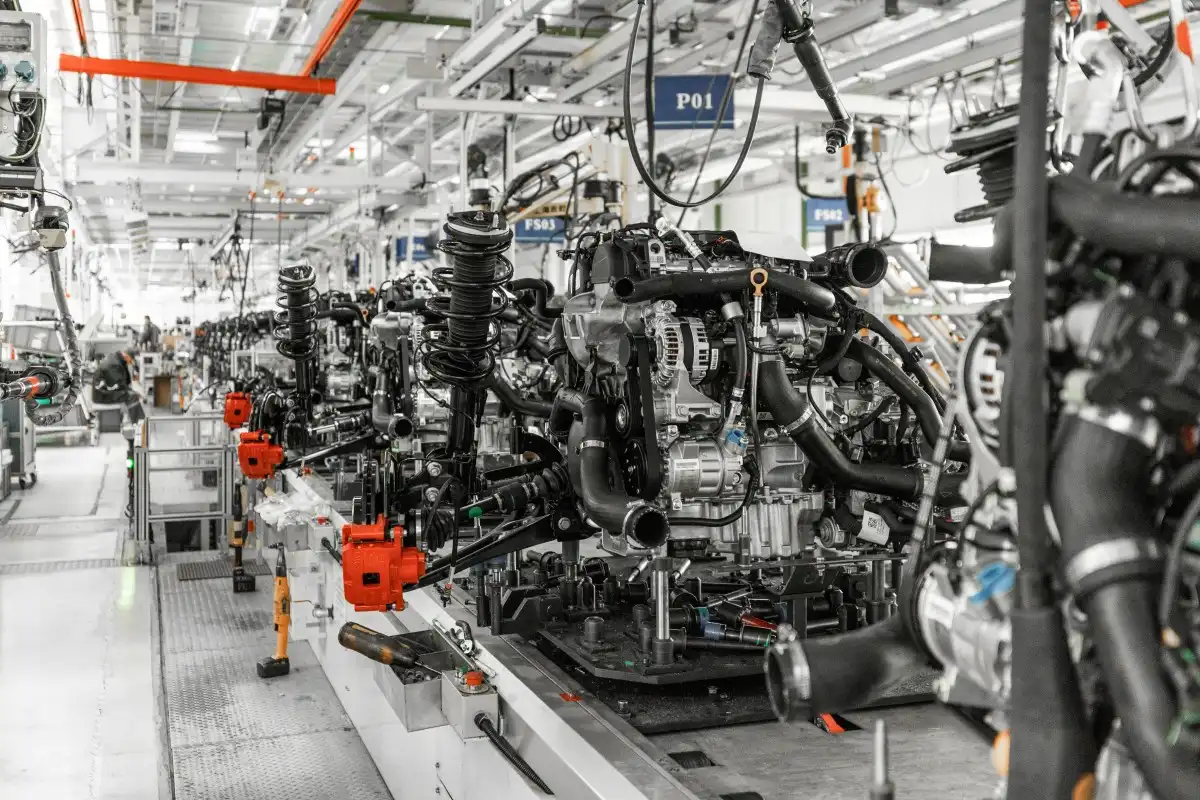

One of the primary challenges in test batch manufacturing is adapting production processes from prototype to small-scale production. This transition often requires significant adjustments to equipment, workflows, and quality control measures. Manufacturers must carefully balance the need for accuracy and quality with the constraints of smaller production runs.

For instance, processes that work well for single prototypes may not be efficient or cost-effective for larger batches. Companies need to develop flexible manufacturing strategies that can accommodate the unique demands of test batch production while still maintaining product integrity and consistency.

Equipment and Tooling Considerations

Test batch manufacturing often requires specialized equipment and tooling that may differ from those used in full-scale production. This can present challenges in terms of investment, setup time, and operator training. Manufacturers must carefully consider whether to invest in dedicated equipment for test batches or find ways to adapt existing machinery.

Additionally, tooling for test batches may need to be more versatile to accommodate potential design changes or variations. This necessitates a balance between flexibility and precision, often leading to increased complexity in tooling design and management.

Material Sourcing and Management

Sourcing materials for test batch manufacturing can be particularly challenging. Suppliers may have minimum order quantities that exceed the needs of a test batch, leading to excess inventory and increased costs. Furthermore, specialty materials required for prototypes or small runs may have longer lead times or higher prices.

Effective material management becomes crucial in test batch production. Manufacturers must develop strategies to minimize waste, manage inventory efficiently, and ensure the availability of necessary materials without overstocking. This often requires close collaboration with suppliers and careful planning of material needs across multiple projects.

Quality Control and Consistency Challenges

Establishing Robust Quality Control Processes

Maintaining consistent quality across test batches is a significant challenge. Unlike large-scale production, where statistical process control methods are well-established, test batch manufacturing often requires more intensive, individualized quality control measures. Each unit in a test batch may need thorough inspection and testing, which can be time-consuming and resource-intensive.

Manufacturers must develop and implement quality control processes that are both rigorous and efficient. This may involve adapting traditional quality control methods or developing new approaches specifically tailored to test batch production. The goal is to ensure that each item in the test batch meets specifications and accurately represents the intended final product.

Dealing with Variability and Inconsistencies

Test batches are more susceptible to variability due to the smaller sample size and potentially less-optimized production processes. Inconsistencies in material properties, manufacturing conditions, or human factors can have a more significant impact on the overall batch quality. Identifying and addressing sources of variability becomes a critical challenge in test batch manufacturing.

To mitigate this, manufacturers often need to implement more stringent process controls and monitoring systems. This might include more frequent checks, tighter tolerance limits, and detailed documentation of production parameters. The goal is to minimize variability while still allowing for the flexibility needed in test production environments.

Balancing Quality and Cost-Effectiveness

Achieving high quality in test batch manufacturing while keeping costs under control is a delicate balancing act. The intensive quality control measures required for test batches can significantly increase production costs. However, compromising on quality can lead to misleading test results or customer dissatisfaction.

Manufacturers must find innovative ways to maintain quality standards without inflating costs excessively. This might involve leveraging advanced technologies like automated inspection systems, developing more efficient testing protocols, or implementing lean manufacturing principles adapted for small-scale production. The key is to focus on critical quality attributes that directly impact product performance and customer satisfaction.

Operational and Logistical Challenges

Managing Production Timelines and Deadlines

Test batch manufacturing often operates under tight timelines, driven by product development schedules, market windows, or customer demands. Managing these timelines effectively while ensuring quality and consistency can be challenging. Delays in material sourcing, equipment setup, or quality control processes can have significant ripple effects on the overall project timeline.

To address this, manufacturers need to develop agile production planning and scheduling systems. This might involve creating buffer times for unexpected issues, implementing just-in-time production techniques, or developing parallel processing methods to optimize workflow. Effective communication and coordination between different departments – from design to production to quality control – are crucial for meeting deadlines without compromising on quality.

Optimizing Workflow and Resource Allocation

Test batch manufacturing often requires a different approach to workflow and resource allocation compared to regular production runs. The smaller scale and potentially more complex nature of test batches can lead to inefficiencies if not managed properly. Manufacturers face the challenge of optimizing their production floor layout, staff allocation, and equipment utilization for these smaller, often more diverse production runs.

Successful test batch manufacturing often involves creating flexible production cells or modules that can be quickly reconfigured for different products or batch sizes. Cross-training staff to handle various aspects of the production process can also enhance flexibility and efficiency. Additionally, implementing lean manufacturing principles, adapted for small-scale production, can help in reducing waste and improving overall operational efficiency.

Handling Documentation and Traceability

Proper documentation and traceability are critical in test batch manufacturing, especially for industries with strict regulatory requirements like medical devices or aerospace. Every aspect of the production process, from material sourcing to final quality checks, needs to be meticulously documented. This level of detail can be challenging to maintain, particularly when dealing with multiple small batches of different products.

Implementing robust documentation systems is essential. This might involve using digital tracking systems, barcode technologies, or even blockchain for enhanced traceability. The challenge lies in creating documentation processes that are thorough yet not overly burdensome on the production team. Striking this balance is crucial for maintaining efficiency while ensuring compliance and quality assurance.

Conclusion

Test batch manufacturing, while crucial for product development and market validation, presents a unique set of challenges. From scaling production processes and maintaining quality consistency to managing tight timelines and optimizing resources, manufacturers must navigate a complex landscape. Success in this domain requires a combination of flexible manufacturing strategies, robust quality control systems, and efficient operational management. By addressing these challenges head-on, companies can leverage test batch manufacturing as a powerful tool for innovation and product refinement, ultimately leading to more successful market launches and satisfied customers.

FAQs

1. What is the typical size of a test batch?

Test batch sizes can vary greatly depending on the industry and product, but generally range from 10 to 1000 units.

2. How long does test batch manufacturing usually take?

The duration can vary widely, typically ranging from a few days to several weeks, depending on product complexity and testing requirements.

3. Is test batch manufacturing more expensive than regular production?

Yes, test batch manufacturing is often more expensive per unit due to smaller scale and more intensive quality control measures.

Expert Test Batch Manufacturing Solutions | BOEN

At BOEN Prototype, we specialize in overcoming the challenges of test batch manufacturing. Our expertise in prototyping and low-volume production for plastic and metal materials makes us the ideal supplier and manufacturer for your test batch needs. We offer comprehensive solutions, from rapid tooling to quality assurance, ensuring efficient and high-quality test batch production. Contact us at contact@boenrapid.com to learn how we can support your product development journey.

References

Smith, J. (2022). "Challenges and Solutions in Test Batch Manufacturing". Journal of Manufacturing Technology, 45(3), 112-128.

Johnson, A. & Brown, L. (2021). "Quality Control Strategies for Small-Scale Production". International Journal of Quality Assurance, 33(2), 78-95.

Wilson, R. (2023). "Optimizing Resource Allocation in Test Batch Production". Manufacturing Process Management, 18(4), 201-215.

Lee, S. et al. (2022). "Material Sourcing Strategies for Prototype and Low Volume Manufacturing". Supply Chain Management Review, 27(1), 55-70.

Garcia, M. & Thompson, K. (2021). "Regulatory Compliance in Test Batch Production: A Case Study Approach". Journal of Regulatory Science, 12(3), 320-335.

Anderson, P. (2023). "Innovative Approaches to Scaling Production from Prototype to Test Batch". Advanced Manufacturing Technology, 40(2), 180-195.