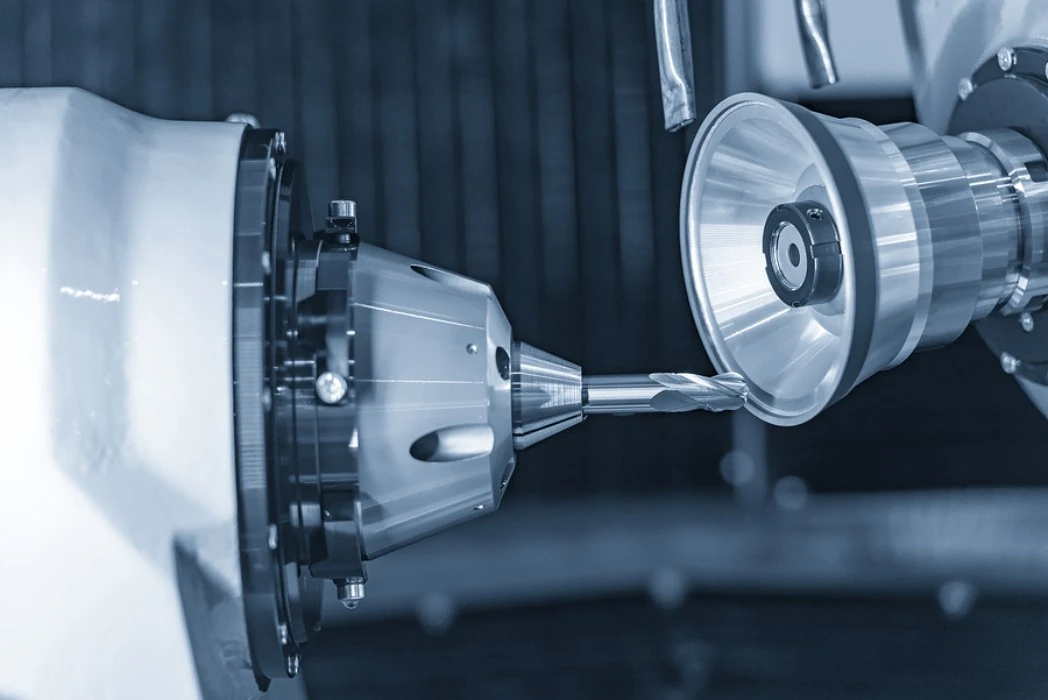

What is 5-Axis CNC Machining and How Does it Work?

5-axis CNC machining is an advanced manufacturing process that utilizes computer-controlled cutting tools to create complex, high-precision parts. Unlike traditional 3-axis machining, which moves along the X, Y, and Z axes, 5-axis CNC machining adds two rotational axes (A and B) for a total of five degrees of freedom. This allows the cutting tool to approach the workpiece from virtually any angle, enabling the creation of intricate geometries, undercuts, and contoured surfaces in a single setup.With great precision and efficiency, the process removes material and shapes the final result by coordinating the movement of the cutting tool and the workpiece according to a set toolpath.

The Fundamentals of 5-Axis CNC Machining

Understanding the Five Axes

At the heart of 5-axis CNC machining lies the concept of movement along multiple axes. The three linear axes - X, Y, and Z - provide motion in three-dimensional space, while the additional rotational axes - A and B - allow for tilting and rotating of the cutting tool or workpiece.The machine can approach the workpiece from nearly any angle thanks to its combination of linear and rotational movement.As a result, machining efficiency is enhanced and the range of feasible geometries is substantially expanded.

Types of 5-Axis Machines

In 5-axis CNC machining, there are two primary types of 5-axis machines: simultaneous and 3+2. Simultaneous 5-axis machines can move all five axes concurrently, allowing for smooth, continuous machining of complex shapes. In contrast, 3+2 axis machines use the two rotational axes to position the cutting tool or workpiece before performing 3-axis machining operations.Both kinds of machines have their benefits over conventional 3-axis machining, but when it comes to making complex components, simultaneous 5-axis machines usually provide more flexibility and efficiency.

The Role of CAD/CAM Software

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software play a crucial role in 5-axis CNC machining.These modern programs permit engineers and mechanics to plan complex parts, mimic machining operations, and produce the exact toolpaths required for 5-axis machining.Advanced CAM software can optimize cutting strategies, minimize tool changes, and reduce cycle times, maximizing the efficiency and capabilities of 5-axis CNC machines.

Advantages and Applications of 5-Axis CNC Machining

Enhanced Precision and Surface Finish

One of the primary advantages of 5-axis CNC machining is its ability to produce parts with exceptional precision and surface finish. Shorter cutting tools with better cutting angles are possible because to the extra axes, which also improves part quality by decreasing vibration.Industries that rely on precise measurements and top-notch surface finishes, including aerospace, medical device production, and high-performance automobile applications, greatly benefit from this degree of accuracy.

Increased Productivity and Efficiency

5-axis CNC machining can significantly boost productivity by reducing setup times and minimizing the need for multiple operations. Complex parts that would traditionally require several setups on a 3-axis machine can often be completed in a single setup on a 5-axis machine.By doing away with the need for several configurations, this not only saves time but also increases precision. Additionally, the ability to machine multiple sides of a part in one operation can lead to faster cycle times and reduced material handling.

Versatility in Part Design and Production

The flexibility offered by 5-axis CNC machining opens up new possibilities in part design and production. Traditional machining techniques would have a hard time reproducing the more complicated and organic structures that engineers are capable of creating. Industries like aerospace, where minimizing weight and optimizing aerodynamic performance are of the utmost importance, greatly benefit from this adaptability.Industries like consumer goods and automobile production may profit from 5-axis machining's superiority in creating molds and dies with intricate geometries.

Challenges and Considerations in 5-Axis CNC Machining

Complexity of Programming and Operation

While 5-axis CNC machining offers numerous advantages, it also presents challenges in terms of programming and operation complexity. Programming efficiently with the extra axes calls for more advanced CAM software and a greater degree of skill.Operators must have a deep understanding of toolpath strategies, collision avoidance, and machine kinematics to fully leverage the capabilities of 5-axis machining. This increased complexity can lead to longer programming times and a steeper learning curve for machinists transitioning from 3-axis to 5-axis machining.

Investment and Cost Considerations

The advanced capabilities of 5-axis CNC machining come with a higher price tag compared to traditional 3-axis machines. The initial investment in 5-axis equipment, software, and training can be substantial. Nevertheless, you should think about the long-term advantages, such higher productivity, shorter setup times, and the capacity to handle more complicated tasks.For many manufacturers, the return on investment (ROI) in 5-axis technology can be significant, particularly when dealing with high-value, complex parts or large production volumes.

Maintenance and Calibration Requirements

5-axis CNC machines require more rigorous maintenance and calibration procedures to ensure optimal performance and accuracy. Accuracy must be checked and adjusted often due to the increased number of axes and the more intricate construction of the machine.This can include geometric accuracy tests, thermal compensation, and advanced probing routines.Although these upkeep tasks increase the total cost of ownership, they are necessary to maintain 5-axis machining's renowned precision and repeatability.

Conclusion

When it comes to manufacturing technology, 5-axis CNC machining is a giant stride forward because of the efficiency, adaptability, and accuracy it provides.By understanding the fundamentals, advantages, and challenges of this advanced machining process, manufacturers can make informed decisions about integrating 5-axis capabilities into their operations.As businesses proceed to request more complex and exact parts, 5-axis CNC machining will without a doubt play an progressively critical part in forming the future of fabricating.

China's 5-axis CNC Machining Manufacturer with Expert Engineers | BOEN

BOEN gives state-of-the-art 5-axis CNC machining arrangements for models and low-volume generation, situating itself at the cutting edge of this industry.With advanced DMG 5-axis CNC machines imported from Germany, BOEN delivers high-speed, high-precision machining for the most demanding industries. To maximize speed and quality, our skilled engineers are masters in creating precise angles, undercuts, and complex geometries all in one setup. The aviation, mechanical autonomy, and car segments are among BOEN's numerous fulfilled clients, much obliged to the company's tremendous capabilities in a wide run of materials. For unparalleled 5-axis CNC machining expertise, contact BOEN at contact@boenrapid.com.

References

1. Smith, J. (2022). Advanced Techniques in 5-Axis CNC Machining. Journal of Manufacturing Technology, 45(3), 178-195.

2. Johnson, R. & Lee, S. (2021). Optimizing Toolpaths for 5-Axis Machining. International Journal of Precision Engineering and Manufacturing, 22(4), 612-628.

3. Brown, A. (2023). The Evolution of CNC Technology: From 3-Axis to 5-Axis Machining. Manufacturing Engineering, 170(2), 45-52.

4. Garcia, M. et al. (2022). Comparative Analysis of Surface Finish in 3-Axis vs. 5-Axis CNC Machining. Journal of Materials Processing Technology, 300, 117345.

5. Wilson, T. (2021). Economic Implications of Implementing 5-Axis CNC Machining in Small to Medium Enterprises. International Journal of Production Economics, 235, 108078.

6. Chen, Y. & Liu, X. (2023). Advancements in CAM Software for 5-Axis CNC Machining. Computer-Aided Design and Applications, 20(3), 534-549.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.