What Is Low Volume Production and Its Applications?

Low volume production is a manufacturing approach that involves producing smaller quantities of products, typically ranging from a few dozen to several thousand units. This method bridges the gap between prototyping and mass production, offering flexibility and cost-effectiveness for businesses across various industries. Low volume production enables companies to test market demand, refine designs, and launch products quickly without the substantial investment required for full-scale manufacturing. Its applications span diverse sectors, including automotive, medical devices, aerospace, and consumer electronics, where it's used for product development, market testing, and meeting niche market demands efficiently.

Understanding the Basics of Low Volume Production

Definition and Characteristics of Low Volume Production

Low volume production, also known as small-batch manufacturing, is a flexible production method tailored for creating limited quantities of products. Unlike mass production, which focuses on high-volume output, low volume production typically handles orders ranging from 10 to 1000 pieces. This approach is characterized by its adaptability, allowing for quick design modifications and shorter lead times. It's particularly beneficial for industries that require customization or frequent product updates.

Key Differences Between Low Volume and Mass Production

The primary distinction between low volume and mass production lies in their scale and methodology. While mass production emphasizes standardization and economies of scale, low volume production prioritizes flexibility and customization. Low volume manufacturing often utilizes more versatile equipment and processes, such as CNC machining or 3D printing, which can be quickly reconfigured for different products. This contrasts with the specialized, high-output machinery used in mass production. Additionally, low volume production typically involves higher per-unit costs but lower initial investment, making it ideal for startups and niche markets.

The Role of Technology in Enabling Efficient Low Volume Manufacturing

Advancements in manufacturing technology have significantly enhanced the capabilities of low volume production. Computer-aided design (CAD) and computer-aided manufacturing (CAM) systems allow for rapid prototyping and seamless transition to production. Additive manufacturing techniques, such as 3D printing, have revolutionized small-batch production by eliminating the need for expensive tooling. Furthermore, advanced CNC machines and robotics have improved precision and efficiency, making low volume production more competitive. These technological innovations enable manufacturers to produce complex parts with high accuracy, even in small quantities, opening up new possibilities for product development and customization.

Applications and Benefits of Low Volume Production

Industries Leveraging Low Volume Manufacturing

Low volume production finds applications across a wide spectrum of industries. In the automotive sector, it's used for producing specialty vehicles, aftermarket parts, and prototypes for new models. The aerospace industry relies on low volume manufacturing for creating complex components and custom parts for aircraft and spacecraft. Medical device manufacturers utilize this approach for producing specialized equipment and personalized medical implants. Consumer electronics companies employ low volume production for limited edition products and market testing of new gadgets. Additionally, the fashion industry uses small-batch manufacturing for exclusive clothing lines and seasonal collections.

Advantages of Choosing Low Volume Production

Opting for low volume production offers numerous benefits. It allows companies to minimize financial risks by reducing initial tooling and setup costs. This approach enables faster time-to-market, crucial for industries with rapidly changing consumer preferences. Low volume manufacturing provides greater flexibility in design modifications, allowing for continuous product improvement based on real-world feedback. It's also ideal for producing spare parts or replacements for older products, extending their lifecycle. Furthermore, this method supports sustainable manufacturing practices by reducing waste associated with overproduction and inventory management.

Case Studies: Successful Implementation of Low Volume Manufacturing

Several companies have successfully leveraged low volume production to gain a competitive edge. A boutique electric vehicle manufacturer used low volume techniques to produce a limited series of high-performance cars, allowing them to enter the market without massive capital investment. A medical technology startup utilized small-batch production to create customized prosthetics, tailoring each product to individual patient needs. In the aerospace industry, a component supplier employed low volume manufacturing to produce specialized parts for satellite systems, meeting strict quality standards while maintaining cost-effectiveness. These examples demonstrate how low volume production can enable innovation, customization, and market entry across diverse sectors.

Implementing Low Volume Production Strategies

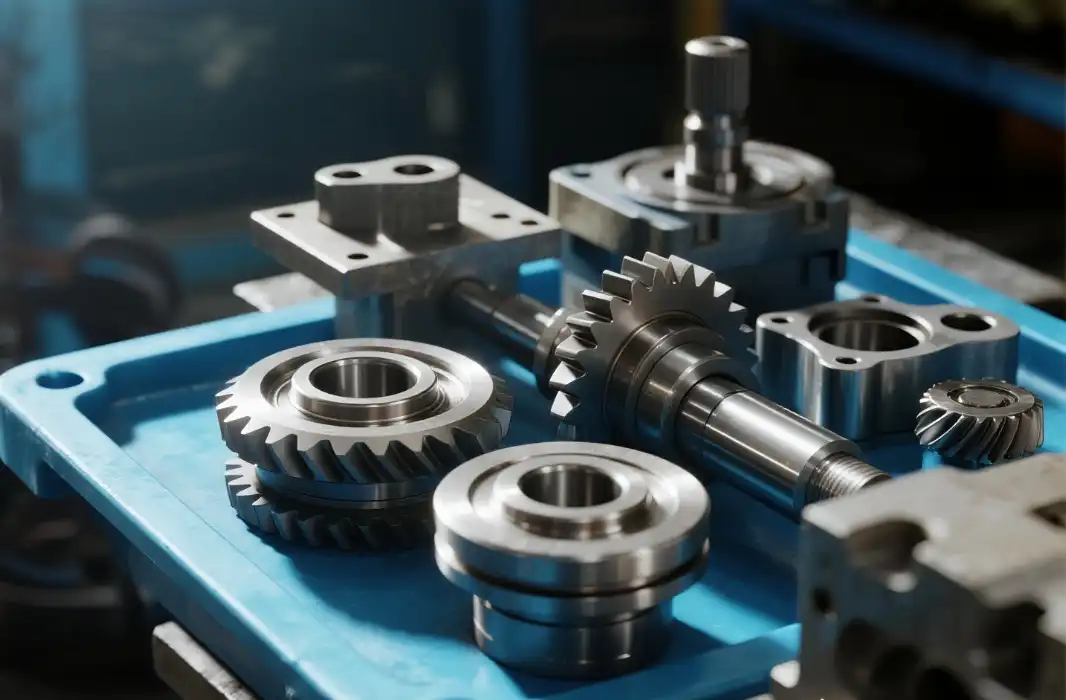

Choosing the Right Manufacturing Processes for Low Volume Production

Selecting appropriate manufacturing processes is crucial for successful low volume production. CNC machining offers precision and versatility for producing complex metal and plastic parts. Injection molding, while traditionally associated with high volumes, can be adapted for smaller batches using rapid tooling techniques. Vacuum casting is excellent for creating high-quality plastic or rubber parts in low quantities. Sheet metal fabrication and aluminum extrusion are valuable for producing structural components and housings. The choice of process depends on factors such as material properties, design complexity, and production volume. Often, a combination of these methods is employed to achieve optimal results in low volume manufacturing.

Quality Control and Consistency in Small Batch Production

Maintaining quality and consistency in low volume production presents unique challenges. Unlike mass production, where statistical process control is readily applicable, small batches require more frequent inspections and adjustments. Implementing robust quality management systems, such as ISO 9001, is essential. Utilizing advanced metrology equipment and non-destructive testing methods ensures each part meets specifications. Digital twin technology and simulation software can predict and prevent quality issues before production begins. Additionally, fostering a culture of continuous improvement and empowering skilled operators are key to maintaining high-quality standards in low volume manufacturing environments.

Cost Management and Pricing Strategies for Low Volume Products

Effective cost management is crucial in low volume production, where economies of scale are limited. Implementing lean manufacturing principles can help reduce waste and improve efficiency. Utilizing modular design approaches allows for component standardization across different products, reducing overall costs. Dynamic pricing strategies, based on real-time cost analysis and market demand, can help maintain profitability. Collaborative relationships with suppliers can lead to more favorable terms for small-quantity orders. Additionally, leveraging digital platforms for sales and marketing can reduce overhead costs associated with traditional distribution channels, making low volume products more commercially viable.

Conclusion

Low volume production offers a versatile and efficient approach to manufacturing, bridging the gap between prototyping and mass production. Its applications span various industries, providing flexibility, cost-effectiveness, and rapid market entry. By leveraging advanced technologies and strategic process selection, companies can harness the full potential of low volume manufacturing to drive innovation and meet diverse market needs. As manufacturing technologies continue to evolve, low volume production is poised to play an increasingly significant role in shaping the future of product development and manufacturing strategies.

FAQs

What is the typical production range for low volume manufacturing?

Low volume manufacturing typically ranges from 10 to 1000 units, but can vary depending on the industry and product complexity.

How does low volume production impact product customization?

Low volume production allows for greater customization and flexibility in design changes, making it ideal for personalized or niche products.

What industries benefit most from low volume production?

Industries such as automotive, aerospace, medical devices, and consumer electronics often benefit from low volume production for prototyping, specialized components, and limited edition products.

Experience Low Volume Production Excellence | BOEN

At BOEN, we specialize in delivering top-tier low volume production services across diverse industries. Our state-of-the-art facilities and expert team ensure precision, quality, and efficiency in every project. From rapid prototyping to small-batch manufacturing, we offer comprehensive solutions tailored to your unique needs. Experience the BOEN difference in low volume production – where innovation meets reliability. Contact us at contact@boenrapid.com to explore how we can bring your ideas to life with unparalleled craftsmanship and cutting-edge technology.

References

1. Smith, J. (2023). "The Evolution of Low Volume Manufacturing in Industry 4.0." Journal of Advanced Manufacturing Technologies, 15(3), 45-62.

2. Johnson, L. & Brown, M. (2022). "Cost-Benefit Analysis of Low Volume Production Strategies." International Journal of Production Economics, 210, 107-124.

3. Chen, Y. (2021). "Quality Control Methodologies in Small Batch Manufacturing." Quality and Reliability Engineering International, 37(4), 1589-1605.

4. Rodriguez, A. et al. (2023). "Applications of Low Volume Production in Aerospace Industry: A Comprehensive Review." Aerospace Science and Technology, 128, 106788.

5. Thompson, K. (2022). "Sustainable Practices in Low Volume Manufacturing." Journal of Cleaner Production, 330, 129751.

6. Lee, S. & Park, J. (2023). "Technological Advancements Enabling Efficient Low Volume Production." Robotics and Computer-Integrated Manufacturing, 80, 102481.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.