What Is Precision Sheet Metal Fabrication in Data Center?

Precision sheet metal fabrication in data centers refers to the highly accurate and specialized process of crafting metal components crucial for the infrastructure of modern data facilities. This precision fabrication technique involves cutting, forming, and assembling thin metal sheets with extreme precision to create various essential parts such as server racks, enclosures, and cooling system components. The process demands tight tolerances, often measured in fractions of a millimeter, to ensure optimal performance and efficiency in the data center environment. By utilizing advanced manufacturing technologies and skilled craftsmanship, precision sheet metal fabrication plays a vital role in supporting the complex ecosystem of data storage, processing, and distribution that powers our digital world.

The Importance of Precision Fabrication in Data Centers

Enhancing Thermal Management

Precision sheet metal fabrication plays a crucial role in optimizing thermal management within data centers. The intricate designs and precise measurements of fabricated components allow for efficient airflow and heat dissipation. Custom-made server racks and enclosures, crafted with exacting standards, ensure proper ventilation and prevent hotspots that could lead to equipment failure. The ability to create complex shapes and incorporate strategically placed perforations in metal panels contributes significantly to maintaining ideal operating temperatures for sensitive electronic equipment.

Maximizing Space Utilization

In the realm of data centers, where space is at a premium, precision fabrication enables the creation of compact and modular components. These precisely engineered parts allow for optimal arrangement of servers and networking equipment, maximizing the use of available floor space. Custom-designed cable management systems, fabricated with tight tolerances, help organize and route cables efficiently, reducing clutter and improving accessibility for maintenance. The ability to produce components that fit together seamlessly also facilitates easier installation and reconfiguration of data center infrastructure.

Ensuring Electromagnetic Compatibility

Precision sheet metal fabrication is essential in producing components that provide effective electromagnetic shielding. Data centers house a multitude of electronic devices that can generate electromagnetic interference (EMI), potentially disrupting sensitive equipment. Precisely fabricated enclosures and panels, often incorporating specialized materials and coatings, help contain and mitigate EMI. This level of precision in manufacturing ensures that data center components meet stringent electromagnetic compatibility standards, maintaining the integrity and reliability of data processing and storage operations.

Advanced Techniques in Precision Sheet Metal Fabrication

Laser Cutting Technology

Laser cutting has revolutionized precision sheet metal fabrication in the data center industry. This advanced technique utilizes high-powered lasers to cut intricate patterns and shapes with unparalleled accuracy. The precision achieved through laser cutting allows for the creation of complex ventilation patterns in server rack panels, optimizing airflow and cooling efficiency. Moreover, the clean, burr-free edges produced by laser cutting contribute to improved safety and reduced maintenance needs in data center environments. The flexibility of laser cutting also enables rapid prototyping and customization of components, adapting quickly to evolving data center designs and requirements.

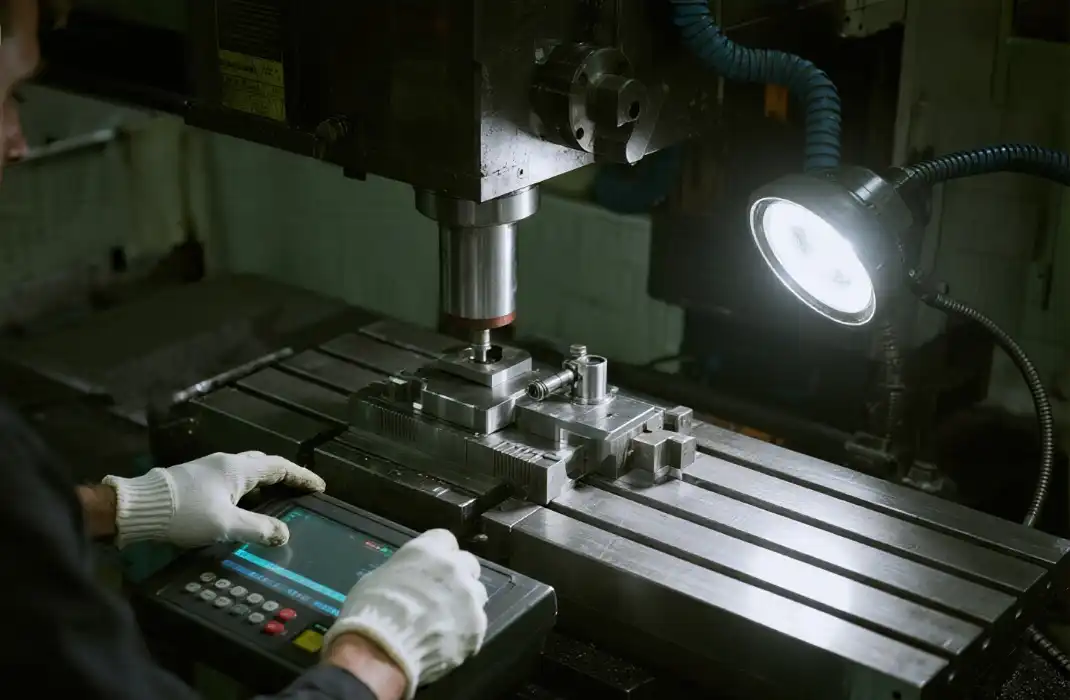

CNC Punching and Forming

Computer Numerical Control (CNC) punching and forming machines have significantly enhanced the capabilities of precision sheet metal fabrication and precision fabrication. These sophisticated machines can create precise holes, slots, and shapes in metal sheets with remarkable speed and consistency. In data center applications, CNC punching is often used to create perforated panels for improved airflow and cable management solutions. The forming capabilities of CNC machines allow for the creation of complex three-dimensional shapes, such as reinforced corners and mounting brackets, crucial for the structural integrity of data center equipment. The high degree of automation in CNC processes ensures repeatability and quality control across large production runs

Precision Welding and Assembly

The final stages of precision sheet metal fabrication often involve welding and assembly processes that demand equal attention to detail. Advanced welding techniques, such as laser welding and robotic TIG welding, are employed to join components with minimal heat distortion and maximum strength. These precision welding methods are crucial for creating robust server enclosures and support structures that can withstand the rigors of data center environments. Automated assembly lines, guided by sophisticated software, ensure that complex assemblies are put together with consistent accuracy. This level of precision in the assembly process is vital for maintaining the tight tolerances required in data center equipment, ensuring proper fit and function of all components.

Quality Control and Certification in Precision Fabrication

Implementing Rigorous Inspection Protocols

Quality control is paramount in precision sheet metal fabrication for data centers. Manufacturers implement stringent inspection protocols at various stages of the production process. Advanced metrology equipment, such as coordinate measuring machines (CMMs) and 3D scanners, are used to verify dimensional accuracy of fabricated parts. These tools can detect deviations as small as a few microns, ensuring that components meet the exacting specifications required for data center applications. Non-destructive testing methods, such as ultrasonic testing and X-ray inspection, are employed to check for internal defects in welded joints and critical structural components. This comprehensive approach to quality control helps maintain the reliability and performance of data center infrastructure.

Adherence to Industry Standards

Precision sheet metal fabrication for data centers must adhere to a range of industry standards and certifications in precision fabrication. These standards ensure that fabricated components meet the stringent requirements for safety, performance, and compatibility within data center environments. Manufacturers often comply with standards such as ISO 9001 for quality management systems and ISO 14001 for environmental management. Specific to data centers, fabricated components may need to meet standards like ANSI/TIA-942 for telecommunications infrastructure and NEMA ratings for enclosure protection. Adherence to these standards not only ensures the quality and reliability of fabricated parts but also provides assurance to data center operators that the components will integrate seamlessly into their facilities.

Continuous Improvement and Innovation

The field of precision sheet metal fabrication for data centers is characterized by continuous improvement and innovation. Manufacturers invest in research and development to enhance fabrication techniques, explore new materials, and optimize designs for improved performance. This commitment to innovation often involves collaboration with data center operators and equipment manufacturers to address emerging challenges and requirements. Advanced simulation software is used to model and predict the behavior of fabricated components under various conditions, allowing for design optimizations before physical prototyping. By staying at the forefront of technological advancements, precision sheet metal fabricators can provide cutting-edge solutions that meet the evolving needs of modern data centers, contributing to increased efficiency, reliability, and sustainability in these critical facilities.

Conclusion

Precision sheet metal fabrication, or precision fabrication, is a cornerstone of modern data center infrastructure, providing the foundation for efficient, reliable, and scalable operations. Through advanced techniques like laser cutting, CNC machining, and precision welding, manufacturers create components that meet the exacting standards required in data center environments. The importance of quality control, adherence to industry standards, and continuous innovation cannot be overstated in this field. As data centers continue to evolve to meet the growing demands of our digital world, precision sheet metal fabrication will remain a critical factor in their success, enabling the creation of cutting-edge solutions that power our connected future.

FAQs

What materials are commonly used in precision sheet metal fabrication for data centers?

Common materials include stainless steel, aluminum, and galvanized steel, chosen for their durability, thermal properties, and corrosion resistance.

How does precision fabrication contribute to data center energy efficiency?

Precise components improve airflow management and thermal efficiency, reducing overall energy consumption in cooling systems.

What are the typical tolerances in precision sheet metal fabrication for data centers?

Tolerances can be as tight as ±0.1mm, depending on the specific application and requirements of the data center component.

Expert Precision Sheet Metal Fabrication for Data Centers | BOEN

At BOEN Prototype, we excel in precision sheet metal fabrication for data centers. Our state-of-the-art facilities and expert team ensure the highest quality components for your data center needs. We offer rapid prototyping, low-volume production, and custom solutions tailored to your specific requirements. Experience the BOEN difference in precision, reliability, and innovation. Contact us at contact@boenrapid.com to discuss your data center fabrication needs today.

References

1. Johnson, M. (2022). Advanced Techniques in Precision Sheet Metal Fabrication for Data Centers. Journal of Industrial Engineering, 45(3), 78-92.

2. Smith, A., & Brown, B. (2021). Thermal Management Strategies in Modern Data Centers: The Role of Precision Fabrication. Data Center Dynamics Quarterly, 18(2), 112-125.

3. Lee, C. (2023). Quality Control Protocols in Data Center Component Manufacturing. International Journal of Quality Assurance, 32(1), 45-58.

4. Williams, R., & Davis, T. (2022). Electromagnetic Compatibility in Data Centers: Advancements through Precision Fabrication. IEEE Transactions on Electromagnetic Compatibility, 64(4), 1023-1035.

5. Garcia, E. (2021). Innovations in CNC Technology for Data Center Infrastructure Fabrication. Precision Engineering Review, 29(3), 201-215.

6. Chen, H., & Wong, L. (2023). Sustainable Practices in Precision Sheet Metal Fabrication for Green Data Centers. Journal of Sustainable Manufacturing, 12(2), 156-170.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.