Where Netherlands Robotics Teams Buy 5-Axis CNC Machining in Asia

BOEN Prototype has emerged as a leading choice for Netherlands robotics teams that are increasingly turning to Asian suppliers for 5-axis CNC machining services. BOEN, which is based in China, specializes in sophisticated 5-axis CNC machining, has a competitive price range, and has a wealth of experience working with robotic components. Their state-of-the-art DMG 5-axis CNC machines, which were imported from Germany, in conjunction with their competent specialists, guarantee the production of parts with a high degree of precision for use in robotics applications. Because of their capacity to manage complicated geometries, strict tolerances, and a wide range of materials, BOEN is the perfect partner for Dutch robotics developers who are looking for a cost-effective and high-quality solution in Asia.

The Rise of Asian 5-Axis CNC Machining for Netherlands Robotics

Growing Demand for Precision Components

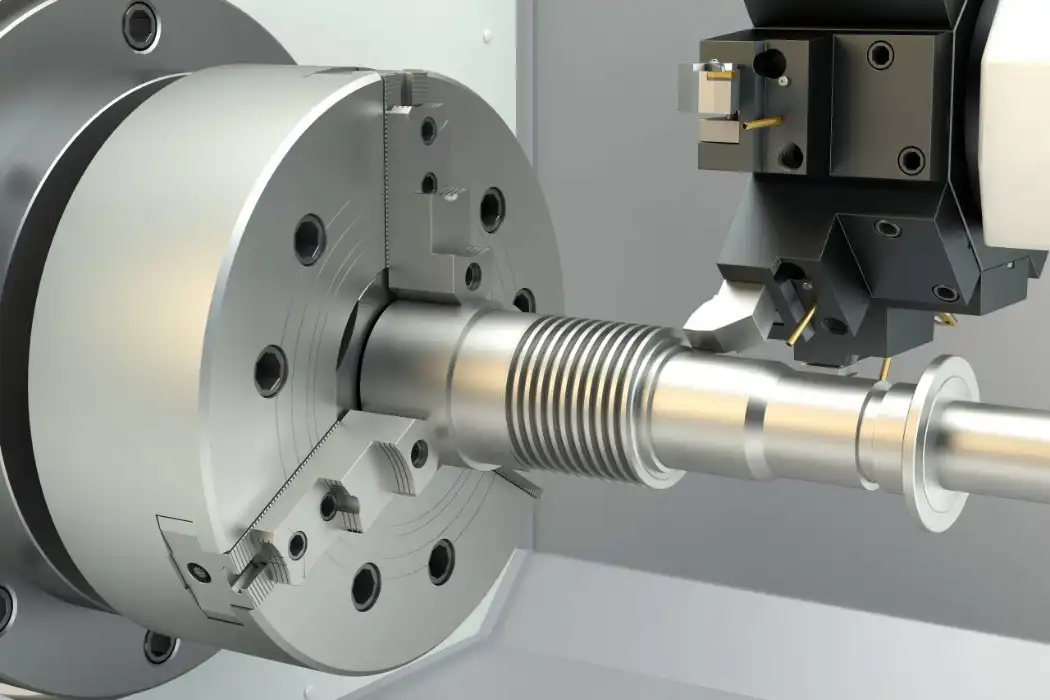

The demand for components that are extremely precise has developed as a result of the rapid growth of the robotics sector in the Netherlands. For the creation of complicated components that have to satisfy the stringent tolerances that are necessary for robotic systems, the use of 5-axis CNC machining has become indispensable. Because of the increased demand, Dutch teams have begun to look at possibilities for sourcing products from around the world, and Asia has surfaced as a market that is competitive when it comes to sophisticated manufacturing services.

Cost-Effectiveness and Quality

Suppliers in Asia, especially those based in countries such as China, have made significant investments in state-of-the-art computer numerical control (CNC) technology. In addition to having lower labor expenses, this investment enables them to provide pricing that is competitive while yet maintaining quality. It has been discovered by robotics teams in the Netherlands that they are able to gain access to skills for 5-axis computer numerical control (CNC) machining that are on par with the very best at a more affordable price. This enables them to distribute resources more efficiently across their various projects.

Technological Advancements in Asian Manufacturing

Many firms in Asia have begun to incorporate the most recent 5-axis CNC machining technologies, frequently obtaining machines from well-known European manufacturers. The Netherlands' dedication to technical innovation guarantees that teams working in the field of robotics are able to take advantage of the most advanced production capabilities that are now available. The capability of manufacturing intricate geometries with a high degree of precision and efficiency has increased the appeal of Asian suppliers to robotics innovators located in the Netherlands.

Benefits of Choosing BOEN for 5-Axis CNC Machining

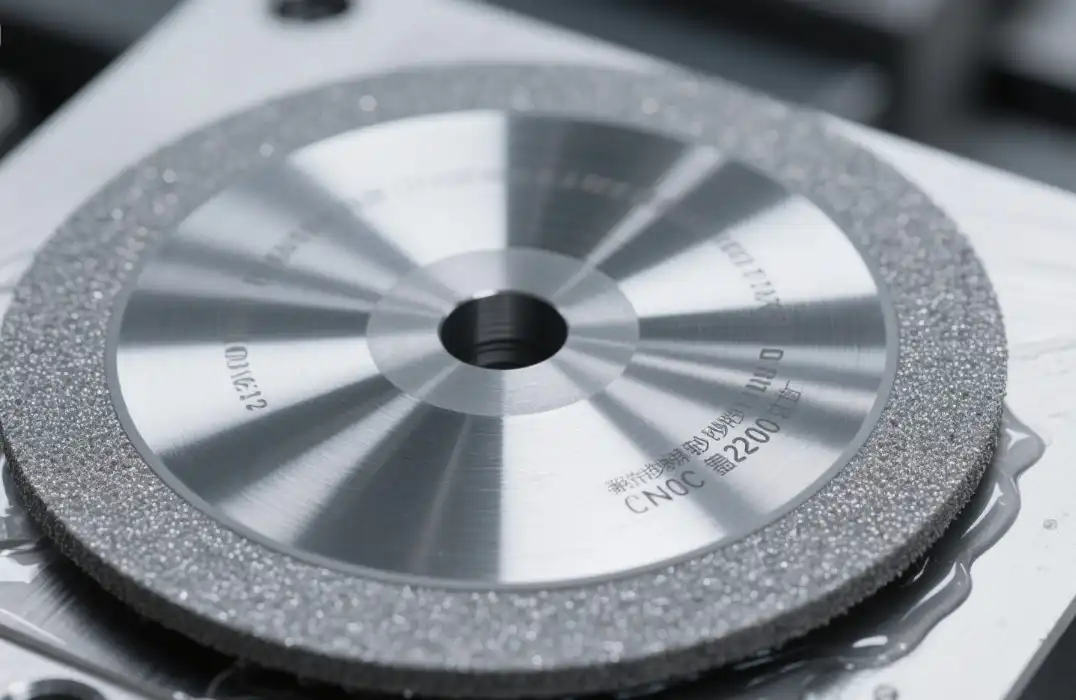

Advanced Machinery and Expertise

Among Asian vendors, BOEN Prototype distinguishes itself with its importation of sophisticated DMG 5-axis CNC machines from Germany. The manufacturing of complicated parts of a high quality, which are critical for robotics applications, is guaranteed by the use of these state-of-the-art equipment in conjunction with BOEN's team of professional machinists and programmers. The company is an excellent choice for collaborations with robotics teams in the Netherlands because of its extensive experience working with a diverse assortment of materials, such as metals and plastics.

Comprehensive Services and Support

In addition to providing machining services, BOEN provides comprehensive support during the entire process of product development. The team they have together gives solutions and useful insights, from the first 3D scanning to the final development of the prototype. Robotics teams who are working on ideas that are creative and may necessitate specific manufacturing methods and iterative development will find this end-to-end service capability to be especially advantageous.

Cost-Effective Solutions for Complex Parts

The 5-axis CNC machining capabilities of BOEN enable the manufacture of intricate components in a single setup, which results in a decrease in overhead expenses, labor costs, and the expenses associated with tooling. Without sacrificing the quality or precision of the components, the Netherlands robotics teams are able to benefit from these cost reductions as a result of this increased efficiency. For the intricate components that are commonly required in robotics, the capability of accomplishing complex geometries and strict tolerances in a single operation is particularly beneficial.

Navigating Challenges in International Sourcing

Communication and Project Management

When working with suppliers from other countries, it is essential to communicate effectively. In order to overcome this difficulty, BOEN hires engineers and project managers who understand English, which facilitates seamless collaboration with robotics teams in the Netherlands. They make use of contemporary project management systems and provide regular updates, so guaranteeing transparency throughout the entire manufacturing process.

Quality Assurance and Standards Compliance

Maintaining standards of quality across international borders might be a cause for concern. By adhering to worldwide quality standards and providing comprehensive quality control systems, BOEN is able to ease this issue. They are able to cooperate with teams from the Netherlands in order to satisfy certain industry or regulatory criteria, and they are able to generate detailed inspection reports. This guarantees that every component meets the standards that are required for applications in the field of robotics.

Intellectual Property Protection

When it comes to the process of outsourcing production, the protection of intellectual property is an important consideration. In order to protect the designs and inventions of their customers, BOEN has put in place strong protocols. They provide confidentiality agreements and practices for secure data management, which gives teams working on robotics in the Netherlands peace of mind while they are sharing sensitive design information for manufacturing purposes.

Conclusion

For the purpose of providing Netherlands robotics teams with 5-axis CNC machining services that are both affordable and of excellent quality, Asian providers such as BOEN Prototype provide appealing options. BOEN distinguishes itself as a dependable partner in the competitive manufacturing landscape of Asia by means of cutting-edge technology, a complete range of services, and a dedication to producing high-quality and precise products. Innovators in the Netherlands are able to speed their robotics development by taking advantage of these capabilities while at the same time maintaining the high standards that are necessary in this cutting-edge industry.

FAQs

What materials can BOEN machine for robotics components?

The materials that BOEN is able to machine encompass a wide variety, including metals, plastics, and composites that are appropriate for use in robotics applications.

In what ways does BOEN guarantee quality assurance to its clientele around the world?

In order to comply with international standards, BOEN utilizes rigorous quality control procedures, which include in-depth inspections and reports.

Is it within BOEN's capabilities to manage both prototyping and production runs?

Yes, prototype development and low to medium scale manufacturing runs are both services that BOEN provides.

Where Netherlands Robotics Teams Buy 5-Axis CNC Machining in Asia | BOEN

For robotics teams in the Netherlands, BOEN Prototype is a market leader in the provision of 5-axis CNC machining services. We have cutting-edge DMG 5-axis CNC machines installed in our state-of-the-art facility, which allows us to manufacture intricate, high-precision components that are critical for applications in the field of robotics. We provide inventors from the Netherlands with a dependable production partner in Asia, owing to our devotion to quality, our proficiency in materials, and our usage of cutting-edge technology. If you have any questions, please do not hesitate to reach out to us at the following email address: contact@boenrapid.com.

References

Dutch Robotics Federation. (2023). "The Growth of Robotics Industry in the Netherlands."

International Journal of Advanced Manufacturing Technology. (2022). "Advancements in 5-Axis CNC Machining for Robotics Applications."

European Robotics Forum. (2023). "Global Sourcing Trends in Robotics Manufacturing."

Asian Manufacturing Association. (2023). "The Rise of Precision Engineering in Asian Markets."

Journal of Robotics and Automation. (2022). "Quality Assurance in International Manufacturing for Robotics."

Global Supply Chain Management Review. (2023). "Intellectual Property Protection in Cross-Border Manufacturing Partnerships."

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.