The Advantages of Aluminum in CNC Machining

Lightweight Yet Strong: The Perfect Balance

CNC machinists love aluminum because of its incredible strength-to-weight ratio. This metal is perfect for uses where every gram counts since it is lightweight but delivers remarkable toughness. In aerospace and automotive industries, aluminum CNC parts contribute to fuel efficiency and improved performance.As a result of the material's inherent strength, strong components may be made from it that can endure high levels of stress and strain without adding unnecessary weight to the finished product.

Corrosion Resistance: Longevity in Challenging Environments

Metals like aluminum stand out due to their natural resistance to corrosion. When exposed to air, aluminum forms a thin oxide layer that acts as a protective barrier against further oxidation. The self-healing quality of aluminum CNC machined components guarantees their durability under challenging conditions. From marine applications to outdoor equipment, aluminum components and aluminum CNC parts offer longevity and reliability, reducing the need for frequent replacements and maintenance.Products with this corrosion resistance last longer and cost less in the long run.

Thermal Conductivity: Efficient Heat Management

When it comes to applications that need effective dissipation of heat, aluminum is the metal of choice due to its great thermal conductivity.CNC machined aluminum parts are often used in heat sinks, cooling systems, and electronic enclosures. A material's capacity to rapidly exchange and scatter warm is basic for ideal execution and hardware life span since it anticipates delicate components from being overheated. Due to the vital nature of temperature control in maintaining the reliability and efficiency of systems, this quality is very advantageous to industries such as electronics and high-performance computing.

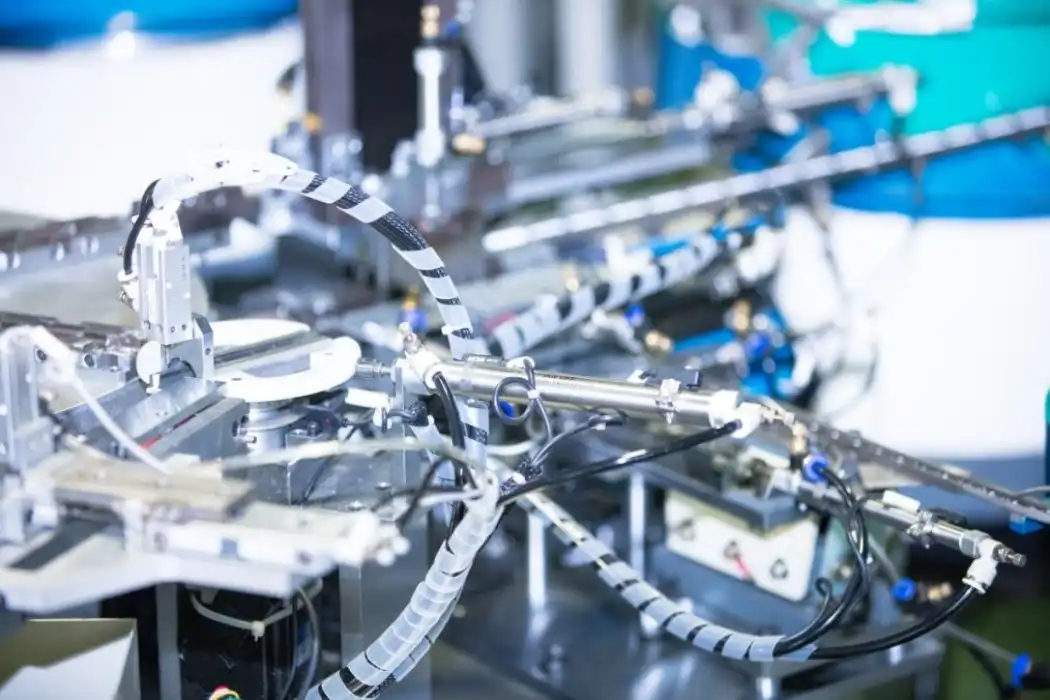

CNC Machining Precision: Unleashing Aluminum's Potential

Achieving Tight Tolerances

For very precise aluminum parts, CNC machining is the way to go.Modern CNC machines can achieve incredibly tight tolerances, often down to micrometers. Industries such as aerospace and medical equipment rely on this degree of precision since even a little error may have a big impact.The combination of aluminum's machinability and CNC technology's precision allows for the creation of complex geometries and intricate features that would be challenging or impossible with other manufacturing methods.The final product's quality and dependability are enhanced by the components' flawless fit and intended functionality, made possible by this meticulous attention to detail.

Surface Finish and Aesthetics

Aluminum CNC machined parts not only offer functional benefits but also deliver aesthetic appeal. From deliberately textured surfaces to ones with a mirror-like smoothness, the material's natural qualities provide for superb surface finishes.CNC machining techniques can produce a variety of finishes, including brushed, polished, or anodized surfaces, enhancing both the appearance and functionality of aluminum CNC parts. This versatility in surface treatment makes aluminum CNC parts suitable for applications where visual appeal is as important as performance, such as in consumer electronics or high-end automotive interiors.

Customization and Rapid Prototyping

The flexibility of CNC machining, combined with aluminum's properties, enables rapid prototyping and customization. A working prototype that closely resembles the finished product may be rapidly created via iterative design processes by engineers and designers. Agile manufacturing reduces the time required to develop a product and put its parts through their paces in the real world before mass production begins.Companies that need unique solutions or frequent modifications will find CNC machining of aluminum to be a useful tool due to its small batch manufacturing capabilities and design flexibility.

Industry Applications: Where Aluminum CNC Parts Shine

Aerospace and Defense

Aluminum CNC machined components are vital in the aerospace and military industries, where minimizing weight is of the utmost importance. From structural components to intricate internal mechanisms, these parts contribute to lighter, more fuel-efficient aircraft and spacecraft. Critical components are manufactured with the accuracy of CNC machining to fulfill the demanding safety and performance criteria of these sectors.Aluminum's erosion resistance too makes it reasonable for parts uncovered to shifting climatic conditions, guaranteeing unwavering quality in assorted operational situations.

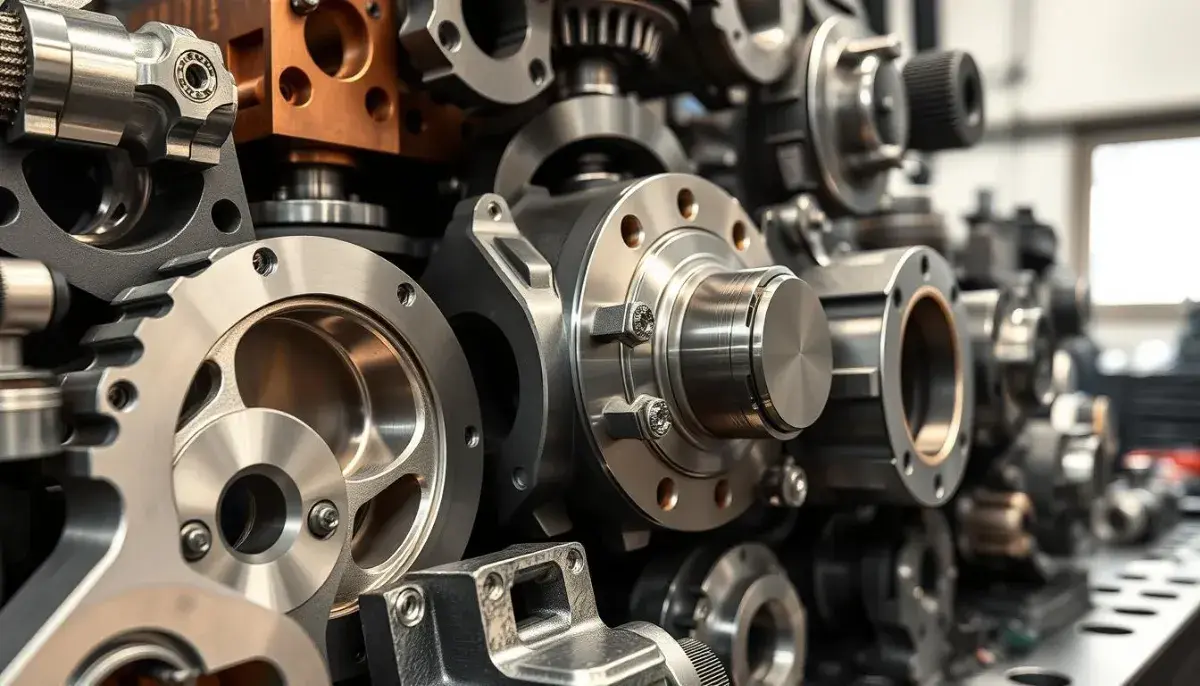

Automotive Innovation

The automotive industry leverages aluminum CNC machined parts to enhance vehicle performance and efficiency. Aluminum CNC parts such as engine components, transmission parts, and chassis elements benefit from aluminum's lightweight properties, contributing to improved fuel economy and reduced emissions. As electric vehicles gain prominence, aluminum CNC parts are increasingly used in battery enclosures and thermal management systems, leveraging the material's heat dissipation capabilities.Complex engine components that maximize power output and efficiency may also be precisely manufactured using CNC machining.

Medical and Healthcare Advancements

Several pieces of medical equipment and gadgets make use of CNC machined aluminum components. The accuracy and durability needed in healthcare settings are provided by these components, which are used in surgical tools and diagnostic devices..Aluminum's biocompatibility and ease of sterilization make it suitable for parts that come into contact with patients or medical professionals.Particularly useful in the development of individualized medical devices or prosthetics is CNC machining's capacity to manufacture bespoke, one-of-a-kind components.

Conclusion

Aluminum CNC machined components are in high demand across numerous industries because of the material's exceptional properties and the precision made possible by CNC technology. Several sectors, including aerospace and healthcare, rely on these components to boost product performance, efficiency, and innovation. The adaptability and dependability of CNC machining aluminum solidify its place as a foundational technique in contemporary manufacturing.Engineers and designers that want to push the limits of what's possible in their areas really need aluminum CNC parts. They're not heavy, sturdy, and won't corrode.

Contact us

With unmatched competence in both prototypes and low-volume production, BOEN Prototype is a frontrunner in high-precision aluminum CNC machining. Deliveries of intricate, precisely machined components that adhere to stringent tolerance requirements are guaranteed by our cutting-edge CNC capabilities. Automotive, healthcare, aerospace, and consumer electronics are just a few of the many sectors that BOEN supports with an emphasis on quick response and outstanding quality. Constant process improvement is driven by our steadfast dedication to changing the game in our business and going above and beyond for our customers. As a result, we make sure that every aluminum CNC part we provide showcases the utmost level of accuracy and functionality.For inquiries about our aluminum CNC machining services, please contact us at contact@boenrapid.com.