Netherlands hardware brands progressively turn to China for die casting services due to a few compelling factors. China's die casting industry offers a combination of cost-effectiveness, progressive innovation, and talented labor that's difficult to coordinate. The country's tremendous fabricating biological system empowers fast turnaround times and adaptability, significant for the fast-paced hardware showcase. Also, Chinese die casting providers have contributed intensely in quality control measures and universal certifications, assembly the tall benchmarks required by Dutch brands. This organization permits Dutch companies to focus on innovation and planning while leveraging China's manufacturing ability, creating a win-win circumstance in the global supply chain.

The Advantages of Chinese Die Casting for Dutch Electronics

Cost-Effective Production at Scale

One of the essential reasons Dutch gadget brands select Chinese die casting services is the critical taken a toll investment in funds. China's well-established fabricating framework and economies of scale permit for generation at lower costs without compromising quality. This cost-effectiveness is vital in the competitive hardware showcase, where benefit edges can be slim.

Moreover, Chinese die casting manufacturing plants frequently have the capacity to handle expansive orders, which is useful for Dutch brands looking to mass-produce electronic components. The capacity to scale generation rapidly and productively is a major advantage, particularly when propelling unused items or sudden increments in demand.

Advanced Technology and Equipment

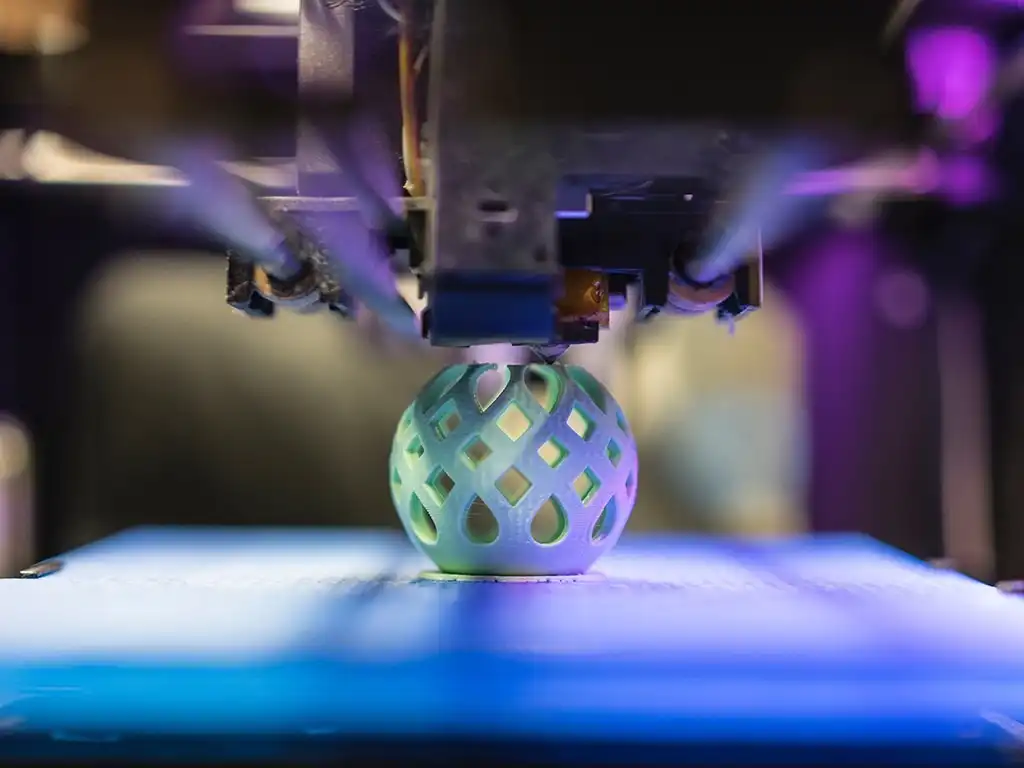

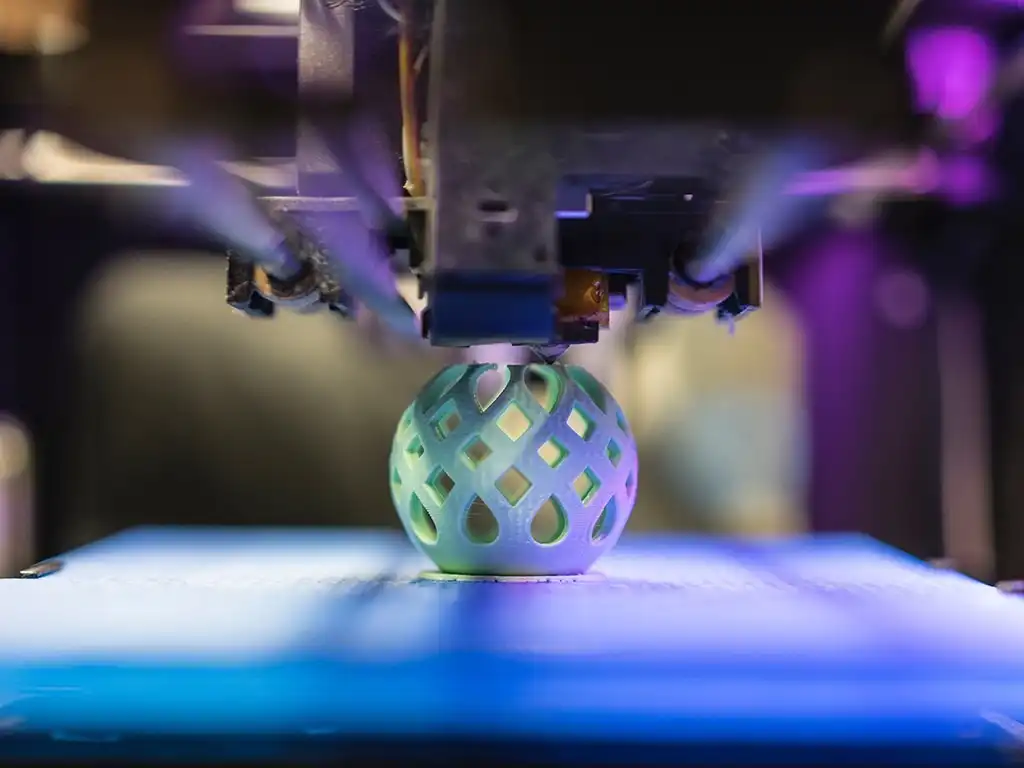

Contrary to obsolete recognitions, numerous Chinese die casting offices are equipped with state-of-the-art technology. These progressive machines and forms guarantee high accuracy and consistency in the generation of complex electronic components. Dutch brands advantage from this mechanical edge, accepting parts that meet their demanding specifications.

The venture in cutting-edge hardware, moreover, implies that Chinese providers can offer a wide extend of die casting capabilities. From thin-walled components to perplexing plans, these offices can handle differing necessities, making them flexible accomplices for Dutch gadget manufacturers.

Skilled Labor and Expertise

China's die casting industry has created a huge pool of gifted specialists with broad involvement in the field. This mastery translates into high-quality yield and the capacity to handle challenging ventures. Dutch brands can tap into this information base to move forward with their product plans and manufacturing processes.

Furthermore, numerous Chinese die casting providers are involved in working with universal clients, including those from the Netherlands. This recognition with worldwide guidelines and honors guarantees smooth communication and collaboration, decreasing potential errors and delays in the generation process.

Quality Assurance and Certification in Chinese Die Casting

Rigorous Quality Control Measures

To meet the high standards of Dutch hardware brands, Chinese die casting providers have executed rigid quality control measures. These frequently incorporate progressed testing hardware, statistical control, and careful review methods. Such thorough quality confirmation makes a difference, keeping up consistency and unwavering quality in the generation of electronic components.

Many Chinese production lines also utilize incline manufacturing standards and Six Sigma strategies to persistently improve their processes. This commitment to quality and proficiency aligns well with the desires of Dutch brands known for their high-quality electronic products.

International Certifications and Standards

Leading Chinese die casting providers have obtained different worldwide certifications, such as ISO 9001 for quality management and ISO 14001 for environmental management. These certifications illustrate their commitment to assembly worldwide benchmarks and give confirmation to Dutch clients around the quality and unwavering quality of their services.

Additionally, numerous Chinese providers are recognizable with European benchmarks and directions, including RoHS and REACH. This information guarantees that the die cast components they create comply with the strict necessities of the European advertise, making them perfect accomplices for Dutch gadget brands.

Customization and Flexibility

Chinese die casting providers frequently offer a high degree of customization to meet the particular needs of Dutch hardware brands. This adaptability permits the generation of special components that may be significant for inventive Dutch electronic items. The capacity to adjust rapidly to unmet needs or plan changes is a critical advantage in the fast-evolving gadgets industry.

Moreover, numerous Chinese providers give value-added services such as design help, prototyping, and post-processing. This comprehensive approach can streamline the item advancement prepare for Dutch brands, reducing time-to-market and overall costs.

Challenges and Solutions in Sourcing Die Casting from China

Communication and Cultural Differences

While dialect boundaries and social contrasts can pose challenges in universal collaborations, numerous Chinese die casting providers have tended to these issues. They frequently utilize English-speaking staff and give clear communication channels to guarantee smooth intuitive with Dutch clients. A few providers indeed offer committed account supervisors familiar with European commerce practices.

To bridge the hole, Dutch companies can consider working with sourcing specialists or building up neighborhood workplaces in China. These middle people can offer assistance in exploring social subtleties and encourage compelling communication between Dutch brands and Chinese suppliers.

Intellectual Property Protection

Concerns approximately intellectual property (IP) security have been a verifiable issue when sourcing from China. In any case, the Chinese government has made critical strides in reinforcing IP laws and enforcement in later a long years. Numerous trustworthy Chinese die casting providers presently have vigorous privacy understandings and measures in put to ensure their clients' IP.

Dutch brands can moderate dangers by carefully checking potential providers, utilizing non-disclosure agreements, and working with providers who have a track record of respecting IP rights. It's moreover fitting to consult with legitimate specialists familiar with Chinese commerce law to ensure appropriate assurances are in place.

Supply Chain Management and Logistics

Managing a supply chain that ranges from China to the Netherlands can be complex. Be that as it may, China's well-developed coordination framework, including effective ports and discussion of cargo choices, makes a difference in moderating these challenges. Numerous Chinese die casting providers offer comprehensive coordination arrangements, dealing with everything from customs clearance to door-to-door delivery.

To optimize their supply chain, Dutch companies can use advanced instruments for real-time tracking and stock management. Building up clear communication conventions and setting practical timelines can moreover offer assistance in overseeing desires and anticipating delays in the generation and conveyance of die cast components.

Conclusion

The choice of Netherlands hardware brands to source die casting from China is driven by a combination of cost-effectiveness, progressed manufacturing capabilities, and quality assurance. Whereas challenges exist, they can be successfully overseen through cautious provider choice and clear communication. As the hardware industry proceeds to advance, the association between Dutch development and Chinese manufacturing expertise is likely to develop stronger, benefiting both sides and contributing to the generation of high-quality electronic items for worldwide customers.

FAQs

What are the main benefits of sourcing die casting from China for Dutch electronics brands?

The main benefits include cost-effectiveness, advanced technology, skilled labor, and the ability to scale production quickly.

How do Chinese die casting suppliers ensure quality for Dutch clients?

They implement rigorous quality control measures, obtain international certifications, and often employ lean manufacturing principles.

What challenges might Dutch companies face when sourcing from China, and how can they be addressed?

Challenges include communication barriers, IP concerns, and supply chain management. These can be addressed through careful supplier selection, clear agreements, and leveraging local expertise or intermediaries.

Expert Die Casting Services | BOEN

At BOEN, we specialize in providing top-tier die casting services tailored to the needs of electronics manufacturers. Our state-of-the-art facilities, experienced team, and commitment to quality make us the ideal partner for Dutch brands seeking reliable die casting solutions. We offer comprehensive services from design optimization to final production, ensuring your components meet the highest standards. Contact us at contact@boenrapid.com to learn how we can support your manufacturing needs.

References

Van der Meer, J. (2021). "Global Sourcing Strategies in the Electronics Industry: A Dutch Perspective." Journal of International Business Studies.

Chen, L. et al. (2020). "Quality Management in Chinese Die Casting: Meeting International Standards." International Journal of Production Research.

Smith, A. (2019). "The Rise of China's High-Tech Manufacturing Sector." Harvard Business Review.

European Commission. (2022). "EU-China Trade and Investment Relations in Challenging Times."

World Bank Group. (2021). "Doing Business in China: Manufacturing Sector Analysis."

Dutch Chamber of Commerce. (2020). "Netherlands-China Economic Relations: Opportunities in Electronics Manufacturing."