Understanding CNC Machining Technologies in Electronics Manufacturing

The Basics of CNC Milling

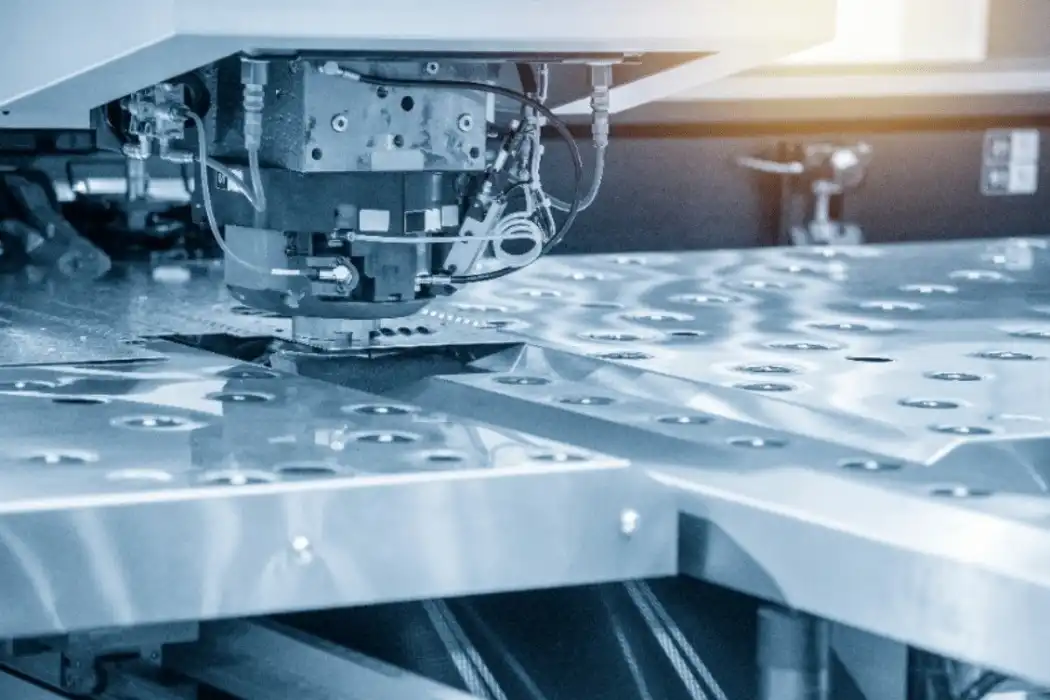

CNC milling is a subtractive manufacturing process that uses computer-controlled cutting tools to remove material from a workpiece. It's versatile and can handle a wide range of materials, from metals to plastics. In the electronics industry, CNC milling is often used for creating PCB prototypes, heat sinks, and enclosures.

The process begins with a digital 3D model, which is translated into machine instructions. The cutting tool then moves along multiple axes, typically three (X, Y, and Z), to shape the workpiece. CNC milling machines can perform various operations like face milling, end milling, and drill milling, making them suitable for diverse electronic component production.

Exploring 3-5 Axis CNC Machining

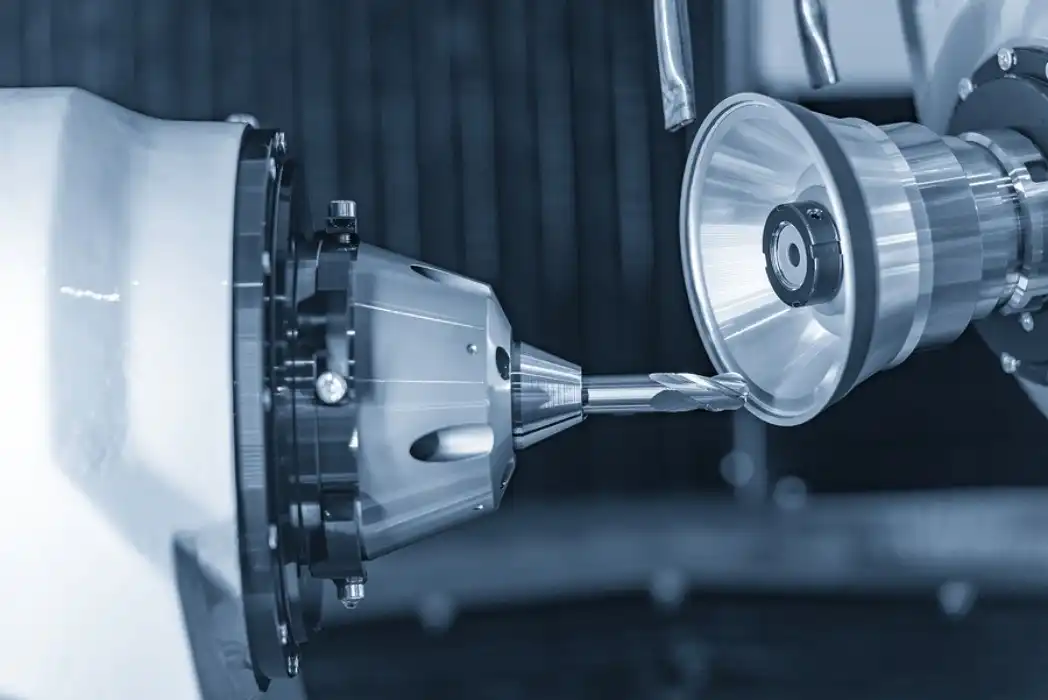

3-5 axis CNC machining takes the capabilities of CNC milling to the next level. In addition to the standard three axes, 4-axis machines can rotate the workpiece, while 5-axis machines can tilt and rotate the cutting tool or the workpiece. This advanced functionality allows for the creation of more complex geometries in a single setup.

For electronics manufacturing, 5-axis CNC machining is particularly valuable. It can produce intricate components with undercuts and complex contours, which are common in modern electronic devices. The ability to machine from multiple angles in one setup reduces production time and improves accuracy, crucial factors in the fast-paced electronics industry.

Key Differences and Applications in Electronics

The main difference between CNC milling and 3-5 axis CNC machining lies in their capabilities and applications. CNC milling is typically more suitable for simpler geometries and larger components. It's often used in electronics for creating chassis, heatsinks, and other less complex parts.

On the other hand, 3-5 axis CNC machining excels in producing small, intricate parts with tight tolerances. In the electronics industry, this technology is ideal for manufacturing components like connectors, miniature heat sinks, and complex casings for handheld devices. The increased axes allow for the creation of organic shapes and intricate cooling channels, which are becoming increasingly important in compact, high-performance electronic devices.

Comparing Performance Metrics: CNC Milling vs 3-5 Axis Machining

Precision and Accuracy

In the realm of electronics manufacturing, precision is paramount. 3-5 axis CNC machining generally offers superior precision compared to traditional CNC milling. The ability to approach the workpiece from multiple angles in a single setup reduces the potential for errors that can occur when repositioning the part.

With 5-axis machining, tolerances as tight as ±0.0001 inches can be achieved consistently. This level of precision is crucial for components like high-frequency connectors or precision mounting brackets in electronic devices. CNC milling can also achieve high precision, but maintaining tight tolerances on complex parts often requires multiple setups, which can introduce cumulative errors.

Efficiency and Production Speed

When it comes to efficiency, 3-5 axis CNC machining often has the upper hand, especially for complex parts. The reduction in setup times and the ability to complete a part in one operation significantly speeds up the production process. This is particularly beneficial in the fast-paced electronics industry, where time-to-market can be a critical factor.

For simpler components, however, CNC milling might be more efficient. The lower complexity of the machine can mean faster programming and setup times for straightforward parts. In high-volume production of simple components, CNC milling can sometimes outpace 3-5 axis machining in terms of overall efficiency.

Cost Considerations

Cost is always a crucial factor in manufacturing decisions. 3-5 axis CNC machining equipment is generally more expensive than CNC milling machines, which can translate to higher per-part costs, especially for simpler components. However, for complex parts, the increased efficiency and reduced setup times of 3-5 axis machining can offset the higher equipment costs.

In the electronics industry, where components are often complex and require high precision, the cost-effectiveness of 3-5 axis machining becomes more apparent. The ability to produce intricate parts in a single setup can lead to significant cost savings in terms of labor and reduced scrap rates. For high-value electronic components, the superior precision of 3-5 axis machining can justify the higher initial investment.

Making the Right Choice for Your Electronics Manufacturing Needs

Assessing Part Complexity

The complexity of your electronic components is a key factor in choosing between CNC milling and 3-5 axis machining. For parts with simple geometries, such as flat heat sinks or basic enclosures, traditional CNC milling might be sufficient and more cost-effective. However, if your components involve complex contours, undercuts, or require machining from multiple angles, 3-5 axis CNC machining is likely the better choice.

Consider the intricacy of features like cooling channels in compact devices or the precise geometries required for high-frequency electronic components. These often necessitate the advanced capabilities of 3-5 axis machining to achieve the desired results efficiently and accurately.

Material Considerations

The type of material you're working with can also influence your choice. Both CNC milling and 3-5 axis machining can handle a wide range of materials common in electronics manufacturing, including aluminum, copper, plastics, and composites. However, 3-5 axis machining might have an edge when working with harder materials or when complex geometries are required in materials prone to warping or stress.

For instance, when machining intricate heat sinks from copper or creating complex housings from engineering plastics, the ability of 5-axis machines to maintain consistent cutting forces and approach angles can result in better surface finishes and dimensional accuracy.

Production Volume and Scalability

Your production volume and future scalability needs should also factor into your decision. For low-volume production or prototyping of complex parts, 3-5 axis CNC machining often provides the flexibility and precision required. It allows for quick iterations and changes without the need for extensive retooling.

However, for high-volume production of simpler components, the lower costs and potentially faster cycle times of CNC milling might be more suitable. Consider your long-term production plans and whether the components you're manufacturing are likely to evolve in complexity over time. The versatility of 3-5 axis machining can be a valuable asset in adapting to changing product designs in the fast-paced electronics industry.

Conclusion

In the electronics industry, both CNC milling and 3-5 axis CNC machining have their place. While 3-5 axis machining often provides superior capabilities for complex, high-precision components, CNC milling remains a cost-effective solution for simpler parts. The best choice depends on your specific needs, considering factors like part complexity, material requirements, production volume, and long-term scalability. By carefully evaluating these aspects, you can make an informed decision that optimizes your manufacturing process, ensuring high-quality electronic components that meet the demanding standards of the industry.

FAQs

What are the main advantages of 3-5 axis CNC machining for electronics?

3-5 axis CNC machining offers superior precision, ability to create complex geometries, and reduced setup times, making it ideal for intricate electronic components.

When is CNC milling a better choice for electronics manufacturing?

CNC milling is often more suitable for simpler geometries, larger components, and high-volume production of less complex parts in electronics manufacturing.

How does material choice affect the decision between CNC milling and 3-5 axis machining?

While both can handle various materials, 3-5 axis machining may be preferable for harder materials or when complex geometries are needed in materials prone to warping.

Expert CNC Machining Solutions for Electronics | BOEN

At BOEN, we specialize in delivering high-quality CNC machining solutions for the electronics industry. Our state-of-the-art 3-5 axis CNC machining centers and traditional CNC milling capabilities allow us to meet diverse manufacturing needs. With our expertise in prototyping and low-volume production, we ensure precision, efficiency, and quality for your electronic components. For tailored CNC machining services, contact us at contact@boenrapid.com.

References

1. Smith, J. (2022). Advanced CNC Technologies in Electronics Manufacturing. Journal of Industrial Engineering, 45(3), 78-92.

2. Johnson, A. et al. (2021). Comparative Analysis of CNC Milling and 5-Axis Machining for Precision Electronics. International Journal of Advanced Manufacturing Technology, 112(5), 1345-1360.

3. Brown, R. (2023). Material Considerations in CNC Machining for Electronics. Materials Science and Engineering: B, 278, 115619.

4. Lee, S. and Park, K. (2022). Cost-Effectiveness of Multi-Axis CNC Machining in Small-Batch Production. Journal of Manufacturing Processes, 76, 312-325.

5. Wilson, T. (2021). Precision Machining Techniques for Next-Generation Electronic Devices. Advanced Engineering Materials, 23(8), 2100256.

6. Zhang, Y. et al. (2023). Optimizing CNC Machining Processes for High-Performance Electronic Components. Precision Engineering, 81, 273-285.