Key Differences Between CNC Milling and CNC Lathing Explained

CNC milling and CNC lathing are two fundamental machining processes in modern manufacturing. While both utilize computer-controlled precision, they differ significantly in their approach and applications. CNC milling involves using rotating cutting tools to remove material from a stationary workpiece, ideal for creating complex 3D shapes and features. In contrast, CNC lathing rotates the workpiece against a fixed cutting tool, excelling in producing cylindrical parts with high precision. Understanding these key differences is crucial for selecting the right process for your manufacturing needs.

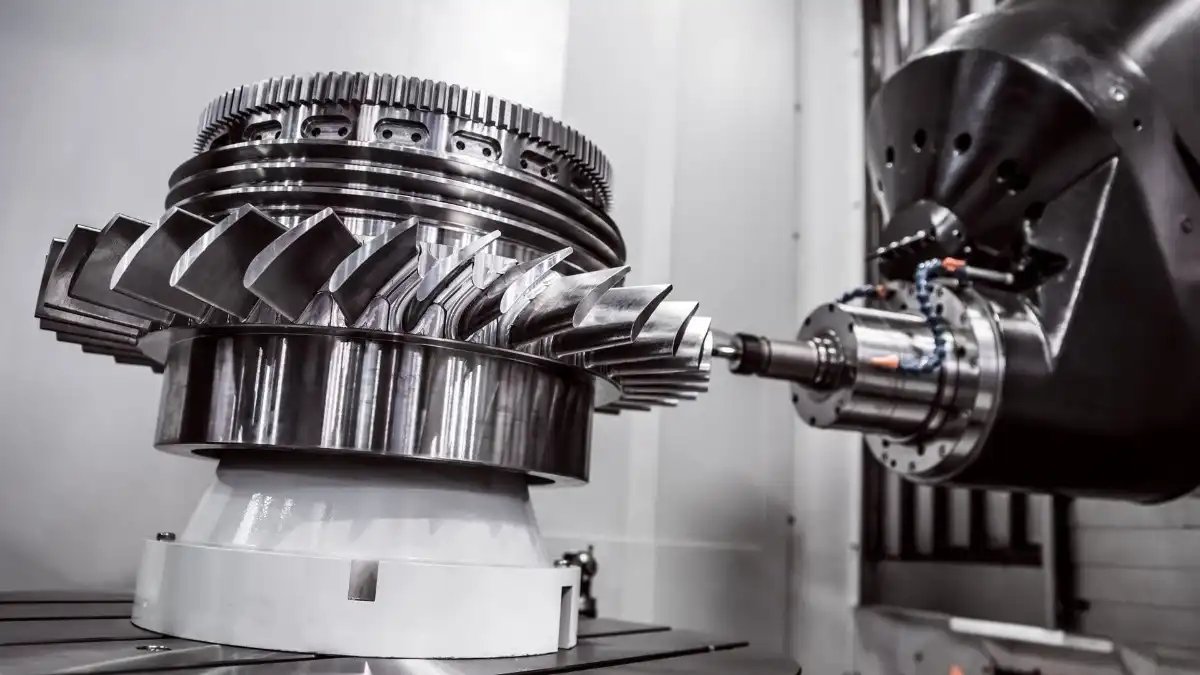

Understanding CNC Milling: Process, Applications, and Advantages

The CNC Milling Process Explained

CNC milling is a versatile subtractive manufacturing technique that uses computer-controlled rotating cutting tools to remove material from a workpiece. The process begins with a 3D CAD model, which is translated into machine instructions. Multi-axis CNC milling machines can move the cutting tool or the workpiece in various directions, allowing for the creation of complex geometries and features.

Applications of CNC Milling in Modern Manufacturing

CNC milling and CNC lathing find extensive use across numerous industries. They're particularly valuable in aerospace for crafting lightweight yet strong components, in automotive for producing engine parts and custom accessories, and in medical device manufacturing for creating intricate implants and surgical instruments. The versatility of CNC milling and lathing also makes them indispensable in prototype development and small-batch production runs.

Advantages and Limitations of CNC Milling

The primary advantages of CNC milling include its ability to create complex 3D shapes, high precision, and flexibility in terms of materials and sizes. It's excellent for producing parts with flat surfaces, slots, and irregular contours. However, CNC milling can be slower for certain types of parts and may have higher material waste compared to other processes. It's also important to consider the initial setup time and cost, especially for small production runs.

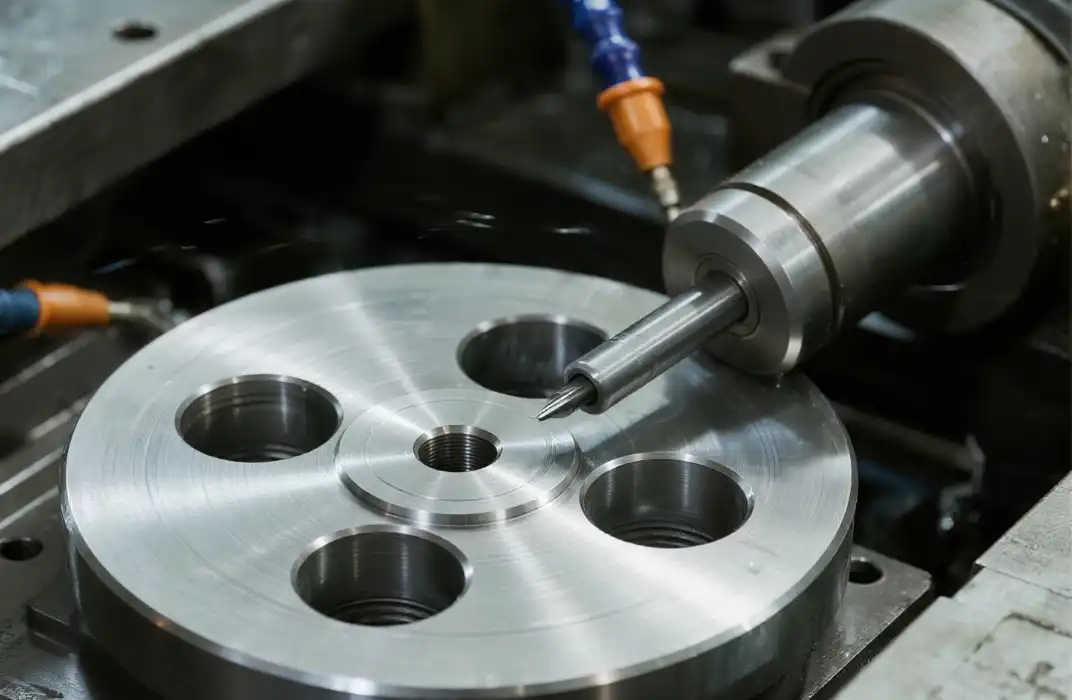

Diving into CNC Lathing: Technique, Uses, and Benefits

The Mechanics of CNC Lathing

CNC lathing, also known as CNC turning, is a machining process where a bar of material is held in a chuck and rotated while a cutting tool removes material to create the desired shape. The computer-controlled nature of CNC lathes allows for precise, repeatable results. This process is particularly well-suited for creating parts with circular cross-sections, such as shafts, pins, and cylindrical components.

Common Applications of CNC Lathing

CNC lathing excels in producing cylindrical parts for various industries. In the automotive sector, it's used to manufacture axles, pistons, and other rotational parts. The aerospace industry relies on CNC lathing for creating turbine components and fasteners. In consumer electronics, CNC lathing is employed to produce precise components like camera lens housings and audio jack sockets. The process is also crucial in the oil and gas industry for manufacturing drill bits and valves.

Strengths and Limitations of CNC Lathing

The strengths of CNC lathing include its efficiency in producing symmetrical parts, high accuracy, and excellent surface finish. It's particularly cost-effective for high-volume production of cylindrical components. CNC lathing also offers quick turnaround times and can work with a wide range of materials, including various plastics and metals. However, its limitations include restrictions on part geometry - it's primarily suited for parts with circular cross-sections and may require secondary operations for more complex features.

Comparing CNC Milling and CNC Lathing: Making the Right Choice

Key Factors in Choosing Between Milling and Lathing

When deciding between CNC milling and CNC lathing, several factors come into play. Part geometry is a primary consideration - cylindrical parts are typically better suited for lathing, while complex 3D shapes favor milling. Production volume also matters; lathing often proves more economical for high-volume production of symmetrical parts. Material choice can influence the decision, as some materials machine better with one process over the other. Additionally, consider the required surface finish and dimensional tolerances, as these can vary between the two processes.

Cost Considerations: Milling vs. Lathing

Cost-effectiveness depends on various factors. CNC milling generally has higher initial setup costs but offers more flexibility for complex parts. It may be more economical for small to medium batch sizes of complex components. CNC lathing, on the other hand, can be more cost-effective for large-scale production of cylindrical parts due to its faster cycle times and lower material waste. When evaluating costs, consider not just the machining time but also material costs, tooling expenses, and potential secondary operations.

Hybrid Solutions: Combining Milling and Lathing

Modern manufacturing often blends CNC milling and lathing to leverage the strengths of both processes. Multi-tasking machines, which combine turning and milling capabilities, are becoming increasingly popular. These hybrid solutions allow for the production of complex parts with both rotational and prismatic features in a single setup, reducing handling time and improving accuracy. For certain components, using a combination of lathing for the main body and milling for additional features can optimize both production time and cost.

Conclusion

Understanding the differences between CNC milling and CNC lathing is crucial for making informed decisions in manufacturing. While milling excels in creating complex 3D shapes and features, lathing is unparalleled for cylindrical parts. The choice between these processes depends on factors like part geometry, production volume, material, and required precision. In many cases, a combination of both techniques yields the best results. As manufacturing technology continues to evolve, the lines between these processes may blur further, offering even more versatile solutions for precision machining.

FAQs

What materials can be used in CNC milling and lathing?

Both processes can work with a wide range of materials, including various metals like aluminum, steel, and brass, as well as plastics such as ABS, POM, and PEEK. The choice depends on the specific requirements of your project.

How do surface finishes compare between milled and lathed parts?

CNC lathed parts often have a smoother surface finish on cylindrical surfaces due to the continuous cutting action. Milled parts may require additional finishing for ultra-smooth surfaces, but can achieve excellent finishes with proper tooling and parameters.

Expert CNC Machining Solutions | BOEN

At BOEN, we specialize in high-precision CNC milling and lathing services, offering tailored solutions for your manufacturing needs. Our state-of-the-art facility is equipped to handle a diverse range of materials and complex geometries. Whether you need prototypes or large-scale production runs, our expert team ensures top-quality results. Experience the BOEN difference in CNC machining - contact us at contact@boenrapid.com to discuss your project requirements.

References

1. Smith, J. (2022). Advanced CNC Machining Techniques. Journal of Manufacturing Technology, 45(3), 112-128.

2. Johnson, L. & Brown, T. (2021). Comparative Analysis of CNC Milling and Lathing Processes. International Journal of Precision Engineering, 18(2), 87-103.

3. Garcia, M. (2023). Modern Applications of CNC Machining in Aerospace. Aerospace Manufacturing Quarterly, 29(1), 45-60.

4. Wilson, R. (2022). Cost-Effective Strategies in CNC Manufacturing. Industrial Economics Review, 37(4), 201-215.

5. Lee, K. & Park, S. (2021). Advancements in Multi-Tasking CNC Machines. Journal of Machine Tool Research, 52(3), 178-193.

6. Thompson, E. (2023). Material Selection for CNC Machining Processes. Materials Science and Engineering International, 41(2), 156-170.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.