The Evolution of CNC Machining in Automotive Manufacturing

Traditional CNC Machining: Laying the Groundwork

The automotive industry has long relied on CNC machining to produce precise parts. Traditional 3-axis CNC machines have been workhorses in manufacturing facilities, capable of creating a wide range of components. But complicated geometries and pieces with many facets are beyond the capabilities of these machines.

The Leap to 5-Axis Technology

The introduction of 5-axis CNC machining marked a significant leap forward. New opportunities for part design and production were made possible by 5-axis machines, which added two rotational axes to the preexisting X, Y, and Z linear axes. You can make complex undercuts and shapes at the same time with this method, which speeds up the process and makes sure the results are accurate.

Simultaneous 5-Axis Machining: The Game Changer

Simultaneous 5-axis machining takes the technology a step further. Unlike positional 5-axis machining, where the part is repositioned between cuts, simultaneous 5-axis machining continuously adjusts all five axes during the cutting process. This capability is perfect for automotive applications because it allows the fabrication of intricate parts with better surface finishes and tighter tolerances.

Advantages of 5-Axis CNC Machining in Automotive Production

Enhanced Precision and Quality

5-axis CNC machining offers unparalleled precision in automotive part production. The ability to approach workpieces from multiple angles allows for tighter tolerances and improved surface finishes. This precision is crucial for components like engine blocks, cylinder heads, and transmission housings, where even minor imperfections can affect performance.

Increased Efficiency and Reduced Setup Time

One of the most significant advantages of 5-axis CNC machining is the reduction in setup time and handling. Complex parts that once required multiple setups and machines can now be produced in a single operation. This not only speeds up production but also reduces the risk of errors associated with part transfers and re-fixturing.

Expanded Design Possibilities

5-axis machining opens up new horizons for automotive designers. Parts with complex geometries, such as turbine blades or aerodynamic body components, can be manufactured with ease. This capability allows for more innovative designs that can improve vehicle performance, fuel efficiency, and aesthetics.

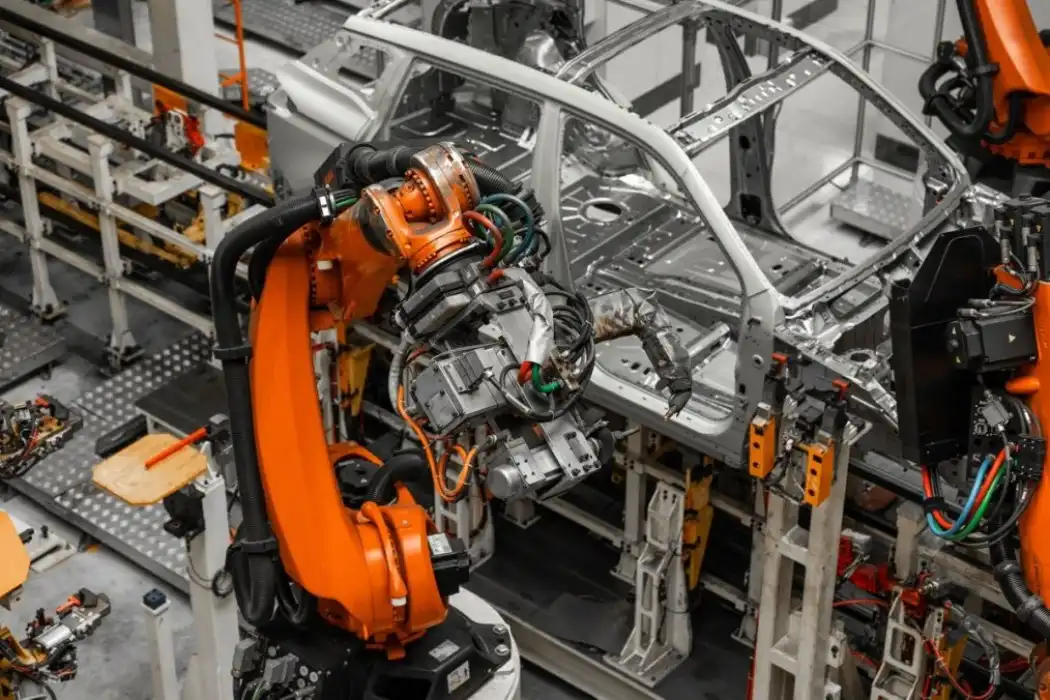

Applications of 5-Axis CNC Machining in the Automotive Industry

Powertrain Components

5-axis CNC machining is highly effective in manufacturing complex powertrain components that demand both precision and durability. Parts like engine blocks, cylinder heads, crankshafts, and camshafts—with intricate geometries and tight tolerances—are perfect candidates for this machine because of its accuracy and precision. It simplifies and speeds up the production process by allowing for the simultaneous creation of cooling channels and oil routes, among other internal features. This ensures the engine will continuously run well, be dependable, and endure long even when put under rigorous operating conditions, and it also simplifies manufacture.

Chassis and Suspension Parts

Chassis and suspension components require strength, accuracy, and lightweight construction, all of which are supported by 5-axis CNC machining. Parts such as control arms, brake calipers, and steering knuckles often feature complex geometries that are best produced using multi-axis capabilities. Optimized material utilization and geometric correctness are made possible by the freedom to manufacture from many angles in one setup. For both everyday and high-performance vehicles, this means improved performance, reduced weight, and increased safety, all of which contribute to greater gas mileage and more responsive handling.

Body and Interior Components

5-axis CNC machining brings exceptional versatility to the production of automotive body and interior components. Its smooth, aerodynamic surfaces make it a popular mold material for use in bodywork, particularly for panels and exterior trims. It allows for the exact machining of premium trim pieces, dashboard parts, and bespoke design components for the inside. This technology is perfect for concept cars and high-end vehicles since it can keep the surface quality and intricate details intact. Manufacturers can efficiently translate complex design intentions into physical parts without sacrificing surface finish or dimensional accuracy.

Conclusion

The fifth pivot In the car division, concurrent CNC machining has driven advancement, effectiveness, and quality, getting to be a imperative innovation. The manufacturing processes in the automobile industry have been transformed by its remarkable capability to produce intricate parts with exceptional precision and minimal setup periods. The use of 5-axis CNC machining in the automobile industry is expected to continue growing as vehicle technology and performance standards continue to rise. This technology allows manufacturers to push the limits of design and engineering.

Fast, Precise 5-Axis CNC for Automotive Manufacturers | BOEN

At BOEN, we specialize in delivering cutting-edge 5-axis CNC machining services tailored for the automotive industry. Our state-of-the-art DMG 5-axis CNC machines, imported from Germany in 2014, represent the pinnacle of precision manufacturing technology. We are able to manufacture intricate vehicle parts with unmatched precision and efficiency thanks to these state-of-the-art machinery.

We take great satisfaction in our capacity to solve even the most difficult automotive component problems, especially those with very complex designs. Cutting down on production time and expenses, our expert programmers and machinists can make intricate forms, undercuts, and angles with only one setup.

Choose BOEN for your automotive CNC machining needs and experience the difference that true precision and efficiency can make in your production process. Get in touch with us at contact@boenrapid.com if you have any questions or would need to conversation almost your extend.