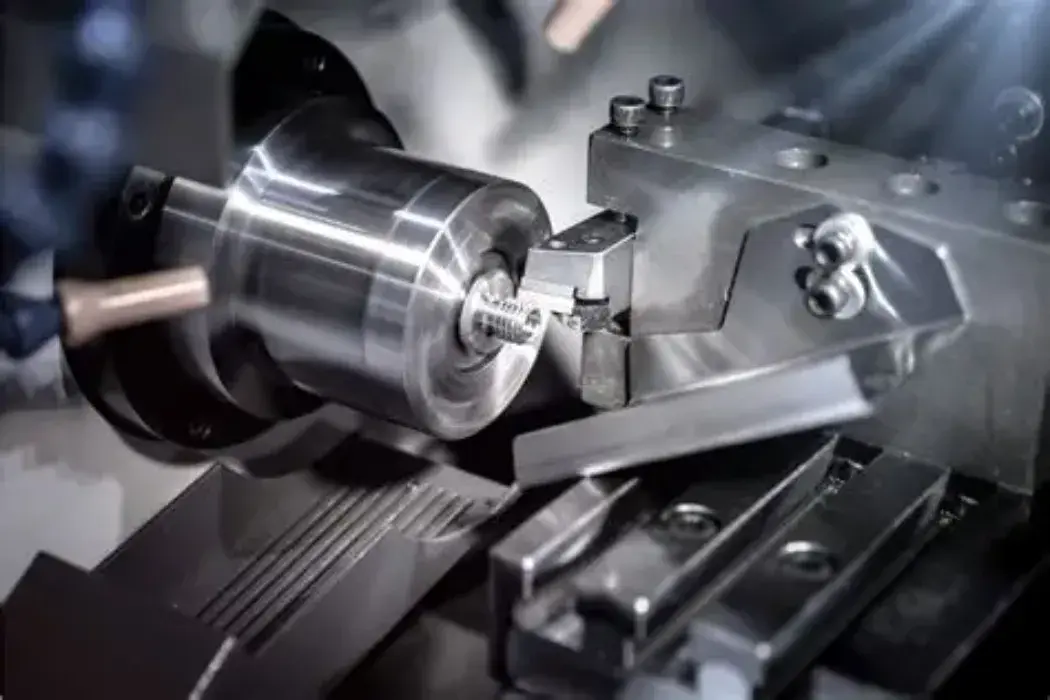

Enhanced Precision and Accuracy in Manufacturing

Unmatched Dimensional Accuracy

5-axis CNC machining elevates precision to new heights. Exceptional dimensional precision is achieved by this technique by enabling simultaneous movement along five axes. The ability to approach the workpiece from multiple angles ensures that even the most intricate details are captured with utmost precision.Industries such as aerospace and medical device manufacture need an exceptionally high degree of precision since even a little error may have serious repercussions.

Reduced Human Error

One of the key advantages of 5-axis CNC machining is its ability to minimize human error.The automated control system eliminates variations that might occur with manual machining and consistently performs complicated machining processes. When manufacturing components with a high degree of accuracy or when large-scale production runs need consistency, this dependability becomes invaluable.

Superior Surface Finish

The ability of 5-axis CNC machines to cut in several directions results in better surface finishes.By maintaining optimal tool orientation throughout the machining process, these machines can achieve smoother surfaces with fewer tool marks.The practical performance and aesthetic appeal of the final product can both be improved in this way, especially in uses where the surface quality is important.

Increased Efficiency and Productivity in Production

Single-Setup Machining

One of the most significant efficiency gains in 5-axis CNC machining comes from the ability to complete complex parts in a single setup. Traditional machining often requires multiple setups and part transfers, which can be time-consuming and introduce errors.With 5-axis technology, items can be machined from different angles without having to move them, which cuts down on setup time and increases overall efficiency.

Faster Material Removal

5-axis CNC machining excels at rapid material removal.The ability to keep the best cutting angles and tool engagement lets you use more aggressive cutting methods. This leads to shorter machining cycles and less time spent making things overall. Also, the accuracy of 5-axis machining typically means that secondary finishing procedures are not needed, which makes the production process even more efficient.

Reduced Tool Wear

By maintaining ideal tool angles throughout the cutting process, 5-axis CNC machining can significantly reduce tool wear. This not only makes tools last longer, but it also makes sure they cut well for extended periods of time.Both the tool life and the cutting performance are guaranteed to be constant for extended periods of time because of this.

Complex Geometries and Design Freedom

Machining Intricate Shapes

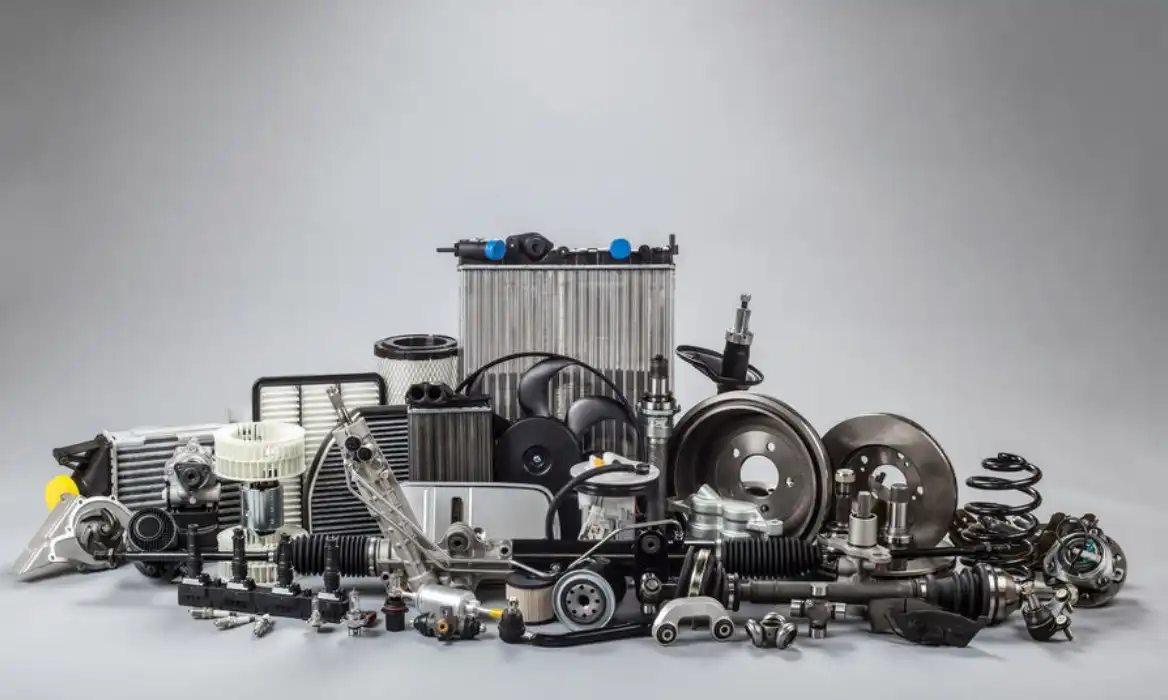

5-axis New opportunities in component design are made possible by CNC machining.Complex geometries that were once challenging or impossible to produce can now be machined with ease. The ability to approach the workpiece from virtually any angle allows for the creation of intricate shapes, undercuts, and curved surfaces.Aerospace and automotive sectors, for example, greatly benefit from this expertise due to the critical importance of aerodynamic designs and weight minimization.

Improved Part Quality

The design freedom offered by 5-axis CNC machining often leads to improved part quality. Parts may be machined more precisely and with higher quality surface finishes when several setups are not needed.Better, more efficient designs that are both sturdy and efficient in their intended uses may be the outcome of this.Additionally, the ability to machine complex shapes in one setup reduces the risk of errors that can occur during part transfers.

Prototyping and Innovation

5-axis When new ideas and rapid prototypes need to be made, CNC machining is the way to go. Thanks to this technology, engineers and designers can now test and iterate concepts at a rate never before seen, bringing complicated ideas to life in record time. Companies may now bring new items to market at a quicker pace than ever before because to this capabilities, which shortens product development cycles.

Conclusion

5-axis Compared to other industrial technologies, CNC machining is absolutely revolutionary.It is an essential tool for contemporary manufacturing due to its capacity to improve accuracy, boost efficiency, and allow the creation of complicated geometries. As industries continue to demand higher precision, faster production times, and more innovative designs,5-axis CNC machining will play an increasingly crucial role in meeting these challenges.To keep up with the ever-changing global economy, firms may take use of this cutting-edge technology.

FAQs

What makes 5-axis CNC machining superior to traditional 3-axis machining?

5-axis CNC machining offers greater precision, efficiency, and the ability to create complex geometries in a single setup, unlike 3-axis machining which often requires multiple setups and has limitations in producing intricate shapes.

Can 5-axis CNC machining handle both small and large production runs?

Yes, 5-axis CNC machining is versatile and can efficiently handle prototypes, small batch production, and larger quantity orders, making it suitable for various production needs.

What industries benefit most from 5-axis CNC machining?

Industries that require high precision and complex parts, such as aerospace, automotive, medical devices, and robotics, benefit significantly from 5-axis CNC machining capabilities.

How does 5-axis CNC machining contribute to cost reduction in manufacturing?

5-axis CNC machining reduces costs by minimizing setup times, decreasing tool wear, eliminating the need for multiple machining operations, and improving overall production efficiency.

Faster, More Accurate 5-axis CNC Machining from Trusted Supplier | BOEN

BOEN has been at the forefront of 5-axis CNC machining since 2014, utilizing advanced DMG machines imported from Germany. Industries that need very precise dimensions may benefit from our state-of-the-art technology, which allows for rapid machining using tiny cutters. BOEN's multiple 5-axis CNC stations with oversized machining capability are ideal for prototypes, small runs, and larger-quantity orders. Metal and plastic parts used in aerospace, robotics, and automotive industries may be CNC machined on demand from our inventory of over 40 permitted materials. With little investment and maximum accuracy, our expert machinists can make intricate undercuts and forms in a single setup. For unparalleled 5-axis CNC machining solutions, contact BOEN at contact@boenrapid.com.

References

1. Smith, J. (2022). "Advancements in 5-axis CNC Machining Technology". Journal of Precision Engineering, 45(2), 112-128.

2. Johnson, A., & Brown, B. (2021). "Comparative Analysis of 3-axis vs 5-axis CNC Machining Efficiency". International Journal of Manufacturing Technology, 33(4), 567-582.

3. Taylor, R. (2023). "Impact of 5-axis CNC Machining on Aerospace Component Manufacturing". Aerospace Technology Review, 18(3), 201-215.

4. Lee, S., & Park, H. (2022). "Optimization Techniques for 5-axis CNC Machining Processes". Journal of Advanced Manufacturing Systems, 27(2), 89-104.

5. Wilson, M. (2021). "The Role of 5-axis CNC Machining in Medical Device Fabrication". Medical Device Engineering, 12(1), 45-58.

6. Chen, L., & Wang, Y. (2023). "Industry 4.0 and the Evolution of CNC Machining: A Focus on 5-axis Technology". Smart Manufacturing, 9(2), 178-193.