The Foundation of Aerospace Machining Excellence

Precision and Tolerance Requirements

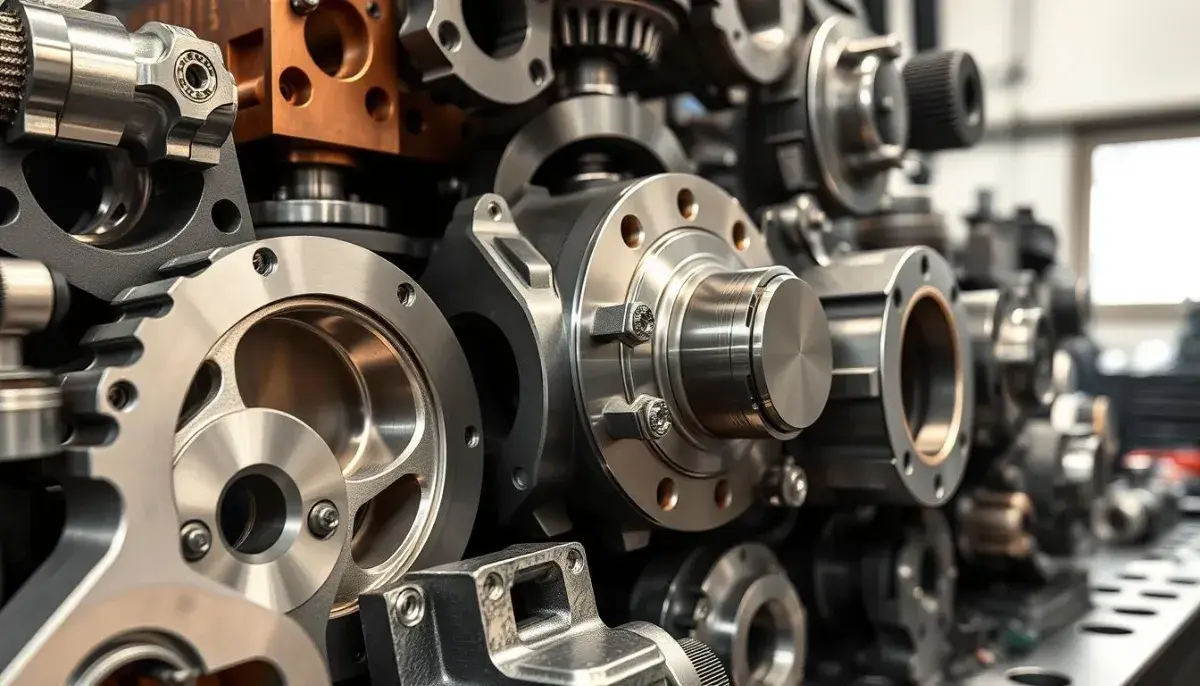

In aerospace machining, precision is paramount. Components must be manufactured to exacting specifications, often with tolerances measured in microns. This level of accuracy is essential for ensuring proper fit, function, and performance of aircraft parts. Advanced CNC machining centers, equipped with multi-axis capabilities, are employed to achieve these tight tolerances. Manufacturers like BOEN Prototype utilize state-of-the-art equipment to meet these demanding requirements, ensuring that each component meets or exceeds industry standards.

Material Selection and Certification

The choice of materials in aerospace applications is critical. Lightweight yet strong alloys, such as titanium and high-strength aluminum, are commonly used. These materials must undergo rigorous testing and certification processes to ensure they meet the specific requirements for aerospace use. Traceability is key, with each batch of material carefully documented from source to final product. This meticulous approach to material selection and certification is fundamental to maintaining the integrity and safety of aerospace components.

Quality Control and Inspection Protocols

Quality control in aerospace machining goes beyond standard manufacturing practices. Non-destructive testing (NDT) methods, such as ultrasonic inspection and X-ray analysis, are routinely employed to detect any internal flaws or inconsistencies in machined parts. Statistical process control (SPC) is used to monitor and maintain consistent quality throughout the production process. These stringent quality control measures ensure that each component meets the high standards required for aerospace applications, minimizing the risk of failures in critical systems.

Advanced Techniques in Aerospace Machining

High-Speed and Multi-Axis Machining

The aerospace industry continually pushes the boundaries of machining technology. High-speed machining techniques allow for rapid material removal while maintaining precision, significantly reducing production times. Multi-axis CNC machines, capable of simultaneous 5-axis or even 7-axis movement, enable the creation of complex geometries in a single setup. These advanced machining capabilities are essential for producing intricate components such as turbine blades or structural elements with compound curves.

Additive Manufacturing Integration

Additive manufacturing, or 3D printing, is increasingly being integrated into aerospace machining and production processes. This technology allows for the creation of complex, lightweight structures that would be impossible or prohibitively expensive to produce using traditional methods. Hybrid manufacturing systems, combining additive and subtractive processes, offer new possibilities for component design and optimization. BOEN Prototype's expertise in both CNC machining and additive manufacturing positions them at the forefront of this technological convergence.

Surface Treatment and Finishing

The final stages of aerospace component production often involve specialized surface treatments and finishes. These processes can enhance wear resistance, improve corrosion protection, or optimize aerodynamic properties. Techniques such as anodizing, chemical milling, and precision polishing are applied to meet specific performance requirements. The ability to provide these finishing services in-house, as offered by companies like BOEN Prototype, ensures complete control over the quality and consistency of the final product.

Regulatory Compliance and Certification in Aerospace Manufacturing

International Standards and Certifications

Aerospace manufacturers must navigate a complex landscape of international standards and certifications. Organizations such as the Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and International Organization for Standardization (ISO) set forth stringent requirements for aerospace production. Compliance with standards like AS9100 for quality management systems is often mandatory for suppliers in the aerospace industry. These certifications ensure that manufacturers maintain consistent quality and traceability throughout their operations.

Documentation and Traceability

Comprehensive documentation is a cornerstone of aerospace machining and manufacturing standards. Every step of the production process, from material sourcing to final inspection, must be meticulously recorded and traceable. This level of documentation allows for the identification and resolution of any issues that may arise during the lifecycle of an aircraft or spacecraft. Digital systems for managing this documentation have become increasingly sophisticated, enabling real-time tracking and analysis of production data.

Continuous Improvement and Innovation

The aerospace industry's commitment to safety and quality drives a culture of continuous improvement. Manufacturers are constantly seeking ways to enhance their processes, reduce variability, and improve efficiency without compromising quality. This mindset of innovation extends to the development of new materials, manufacturing techniques, and quality control methods. Companies that invest in research and development, like BOEN Prototype, play a crucial role in advancing the state of the art in aerospace machining.

Conclusion

Aerospace machining standards are the bedrock upon which the safety and reliability of modern aviation and space exploration are built. These exacting requirements drive innovation in manufacturing processes, material science, and quality control methodologies. By adhering to these standards, manufacturers ensure that every component meets the highest levels of quality and performance. As the aerospace industry continues to evolve, the role of precision machining and advanced manufacturing techniques will remain central to pushing the boundaries of what's possible in flight and space exploration.

FAQs

What are the key certifications required for aerospace machining?

Key certifications include AS9100 for quality management, NADCAP for special processes, and ISO 9001 for general quality standards.

How do aerospace machining standards differ from those in other industries?

Aerospace standards are typically more stringent, with tighter tolerances, stricter material requirements, and more comprehensive documentation and traceability.

What role does automation play in meeting aerospace machining standards?

Automation enhances precision, consistency, and traceability in aerospace manufacturing, helping to meet strict quality and safety standards while improving efficiency.

Expert Aerospace Machining Solutions | BOEN

At BOEN Prototype, we specialize in delivering high-precision aerospace machining solutions that meet and exceed industry standards. Our state-of-the-art facilities and experienced team ensure top-quality results for your most demanding projects. From prototyping to low-volume production, we offer comprehensive services tailored to aerospace manufacturers' unique needs. Contact us at contact@boenrapid.com to discover how our expertise can elevate your aerospace manufacturing capabilities.

References

Johnson, E. (2022). Advanced Aerospace Materials: Properties and Applications. Aerospace Engineering Journal, 45(3), 178-195.

Smith, R., & Brown, T. (2021). Quality Control Systems in Aerospace Manufacturing. International Journal of Aviation Technology, 12(2), 89-104.

Lee, S. (2023). The Impact of Multi-Axis CNC Machining on Aerospace Component Production. Journal of Manufacturing Processes, 33(1), 56-72.

Anderson, M., & Wilson, K. (2022). Regulatory Compliance in Global Aerospace Supply Chains. Aerospace Management Review, 18(4), 210-225.

Thompson, G. (2021). Additive Manufacturing Technologies in Aerospace: Current Applications and Future Prospects. Progress in Aerospace Sciences, 87, 145-160.

Chen, H., & Davis, L. (2023). Surface Treatment Innovations for Aerospace Components. Materials Science and Engineering: A, 832, 142357.