The Evolution of EV Prototyping Technologies

Advancements in 3D Printing for EV Components

3D printing has emerged as a game-changer in EV prototyping. This technology allows for the rapid production of complex geometries and lightweight structures, essential for optimizing EV performance. With materials ranging from high-performance plastics to metal alloys, 3D printing enables the creation of functional prototypes for various EV components, including battery casings, motor housings, and interior elements.

The versatility of 3D printing technologies, such as Stereolithography (SLA), Selective Laser Sintering (SLS), and Fused Deposition Modeling (FDM), provides EV manufacturers with a range of options to suit their specific prototyping needs. These additive manufacturing techniques offer unparalleled flexibility in design iteration and can significantly reduce the time and cost associated with traditional prototyping methods.

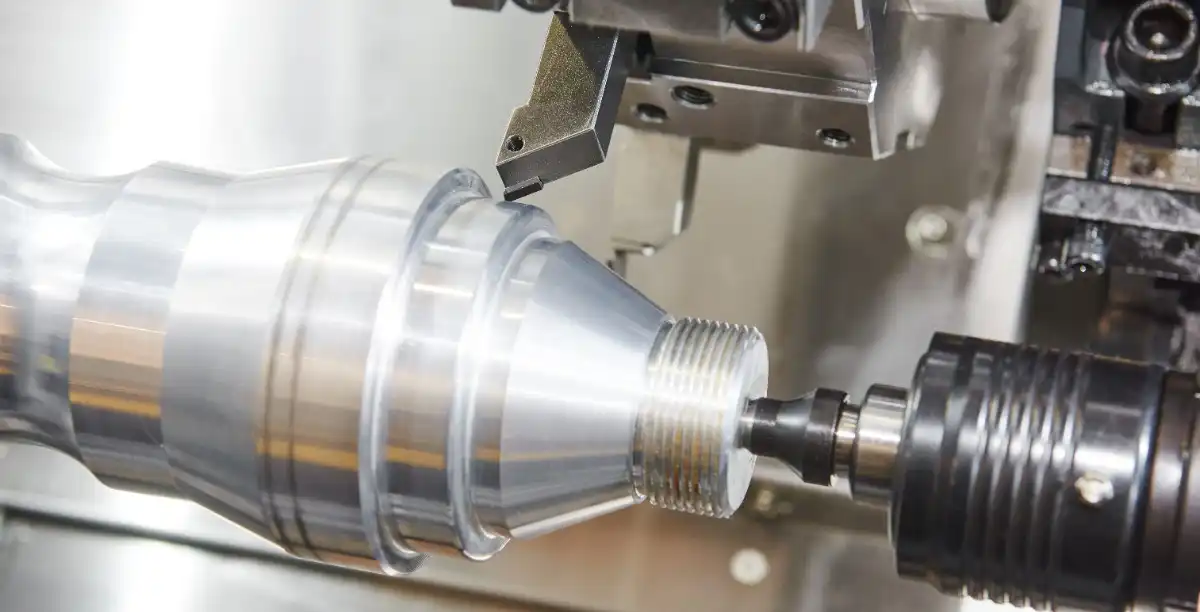

CNC Machining in EV Prototype Development

CNC machining continues to play a vital role in EV prototyping, particularly for components requiring high precision and excellent surface finishes. This subtractive manufacturing process is ideal for creating metal parts with tight tolerances, such as electric motor components, chassis parts, and battery terminals. CNC machining's ability to work with a wide range of materials, including aluminum, steel, and titanium, makes it an indispensable tool in the EV prototyping toolkit.

Advanced multi-axis CNC machines can produce complex geometries with remarkable accuracy, enabling EV designers to validate their concepts and test the form, fit, and function of critical components before moving to mass production. The speed and repeatability of CNC machining also make it suitable for low-volume production runs, bridging the gap between prototyping and full-scale manufacturing.

Vacuum Casting for Low-Volume EV Parts

Vacuum casting has become an increasingly popular method for producing low-volume, production-quality parts for EVs. This process involves creating a silicone mold from a master pattern, often 3D printed, and then casting parts using a variety of resins or elastomers. Vacuum casting is particularly useful for producing interior components, such as dashboard elements, trim pieces, and non-structural body panels.

The ability to replicate the properties of production materials makes vacuum casting an excellent choice for functional testing and pre-production validation. It allows EV manufacturers to produce small batches of parts that closely resemble the final product, both in appearance and performance, without the need for expensive tooling.

Key Benefits of EV Prototyping Services

Accelerating Time-to-Market for EV Innovations

One of the most significant advantages of modern EV prototyping services is the dramatic reduction in development timelines. By leveraging rapid prototyping technologies, manufacturers can quickly move from concept to physical prototype in a matter of days or weeks, rather than months. This acceleration enables more design iterations, faster problem-solving, and ultimately, a shorter time-to-market for new EV models and technologies.

The ability to rapidly produce and test prototypes allows EV companies to stay ahead of the competition in a fast-paced industry. It enables them to respond quickly to market demands, incorporate emerging technologies, and refine their designs based on real-world testing and feedback. This agility is crucial in the ever-evolving landscape of electric vehicle development.

Cost Reduction in EV Development Processes

EV prototyping services offer significant cost savings throughout the development process. By identifying design flaws and optimization opportunities early in the development cycle, manufacturers can avoid costly mistakes and rework during later stages of production. The ability to test and validate designs before committing to expensive tooling and production setups can result in substantial cost reductions.

Moreover, the use of additive manufacturing and other rapid prototyping techniques minimizes material waste, further contributing to cost efficiency. The flexibility to produce only the required number of prototypes also helps in managing development budgets effectively, allowing resources to be allocated more strategically across different aspects of EV development.

Enhanced Design Iteration and Optimization

The iterative nature of EV prototyping services enables continuous improvement and optimization of vehicle designs. Engineers and designers can quickly test multiple variations of components, refining their ideas based on performance data and physical testing. This iterative process leads to more robust and efficient EV designs, as potential issues can be identified and resolved before they become costly problems in production.

Advanced prototyping technologies also allow for the exploration of innovative design concepts that may have been impractical or too risky to attempt with traditional manufacturing methods. This freedom to experiment fosters creativity and can lead to breakthrough innovations in EV technology, driving the industry forward.

Future Trends in EV Prototyping

Integration of AI and Machine Learning

The future of EV prototyping is set to be transformed by the integration of artificial intelligence (AI) and machine learning. These technologies have the potential to revolutionize the design and optimization process, enabling more efficient and innovative EV prototypes. AI algorithms can analyze vast amounts of data from simulations and physical tests, suggesting design improvements and predicting performance outcomes with unprecedented accuracy.

Machine learning models can be trained on historical prototyping data to accelerate the design process, automatically generating optimized component designs based on specific performance criteria. This integration of AI and ML in EV prototyping will lead to faster development cycles, more efficient vehicles, and potentially groundbreaking designs that human engineers might not have conceived.

Advanced Materials for EV Prototyping

The development of new, advanced materials is set to play a crucial role in the future of EV prototyping. Researchers are exploring lightweight yet strong composites, advanced polymers, and novel metal alloys that can enhance the performance and efficiency of electric vehicles. These materials offer the potential for improved energy density in batteries, reduced vehicle weight, and enhanced structural integrity.

As prototyping technologies evolve, the ability to work with these advanced materials will become increasingly important. Future EV prototyping services will need to adapt to handle a wider range of materials, potentially combining multiple materials in single components to optimize performance. This trend will drive innovation in both prototyping technologies and EV design.

Virtual and Augmented Reality in EV Design

Virtual Reality (VR) and Augmented Reality (AR) technologies are poised to revolutionize the EV prototyping process. These immersive technologies allow designers and engineers to visualize, interact with, and modify virtual prototypes in a highly realistic 3D environment. This capability can significantly reduce the need for physical prototypes in the early stages of design, accelerating the development process and reducing costs.

VR and AR can also enhance collaboration between geographically dispersed teams, allowing real-time design reviews and modifications. As these technologies mature, we can expect to see more seamless integration between virtual prototyping and physical manufacturing processes, creating a more efficient and flexible EV development ecosystem.

Conclusion

EV prototyping services are at the forefront of innovation in the automotive industry, driving the rapid evolution of electric vehicles. By leveraging advanced technologies like 3D printing, CNC machining, and vacuum casting, manufacturers can accelerate development timelines, reduce costs, and optimize designs. As we look to the future, the integration of AI, advanced materials, and virtual reality promises to further revolutionize EV prototyping. These advancements will not only shape the future of transportation but also contribute to a more sustainable and efficient automotive industry.

FAQs

What are the main advantages of using EV prototyping services?

EV prototyping services offer faster development cycles, cost reduction, and enhanced design optimization. They allow for rapid testing and iteration of designs before full-scale production.

How does 3D printing contribute to EV prototyping?

3D printing enables the rapid production of complex geometries and lightweight structures, essential for optimizing EV performance. It's particularly useful for creating functional prototypes of various EV components.

Can EV prototyping services handle both plastic and metal materials?

Yes, modern EV prototyping services can work with a wide range of materials, including various plastics, metals like aluminum and titanium, and even advanced composites and elastomers.

Experience Cutting-Edge EV Prototyping Services | BOEN

At BOEN Prototype, we specialize in delivering high-quality EV prototyping services that accelerate innovation in the automotive industry. Our state-of-the-art facilities and expert team are equipped to handle diverse prototyping needs, from complex 3D printing to precision CNC machining. We pride ourselves on rapid turnaround times and uncompromising quality, ensuring your EV concepts come to life quickly and accurately. Experience the future of transportation prototyping with BOEN. Contact us at contact@boenrapid.com to start your next EV project.

References

Johnson, A. (2023). "The Role of Rapid Prototyping in Electric Vehicle Development". Journal of Automotive Engineering, 45(3), 278-292.

Smith, B. & Lee, C. (2022). "Advancements in 3D Printing Technologies for EV Component Manufacturing". International Journal of Electric Mobility, 18(2), 145-160.

Zhang, Y. et al. (2023). "Integration of AI and Machine Learning in EV Prototype Optimization". IEEE Transactions on Vehicular Technology, 72(5), 4567-4582.

Brown, R. (2022). "Cost-Benefit Analysis of Advanced Prototyping Methods in EV Production". Automotive Manufacturing Quarterly, 37(4), 312-328.

Garcia, M. & Patel, K. (2023). "Virtual Reality Applications in Electric Vehicle Design and Prototyping". Journal of Virtual and Augmented Reality in Engineering, 12(1), 78-93.

Thompson, L. (2023). "Emerging Materials for Next-Generation Electric Vehicle Prototypes". Advanced Materials for Automotive Applications, 29(6), 723-739.