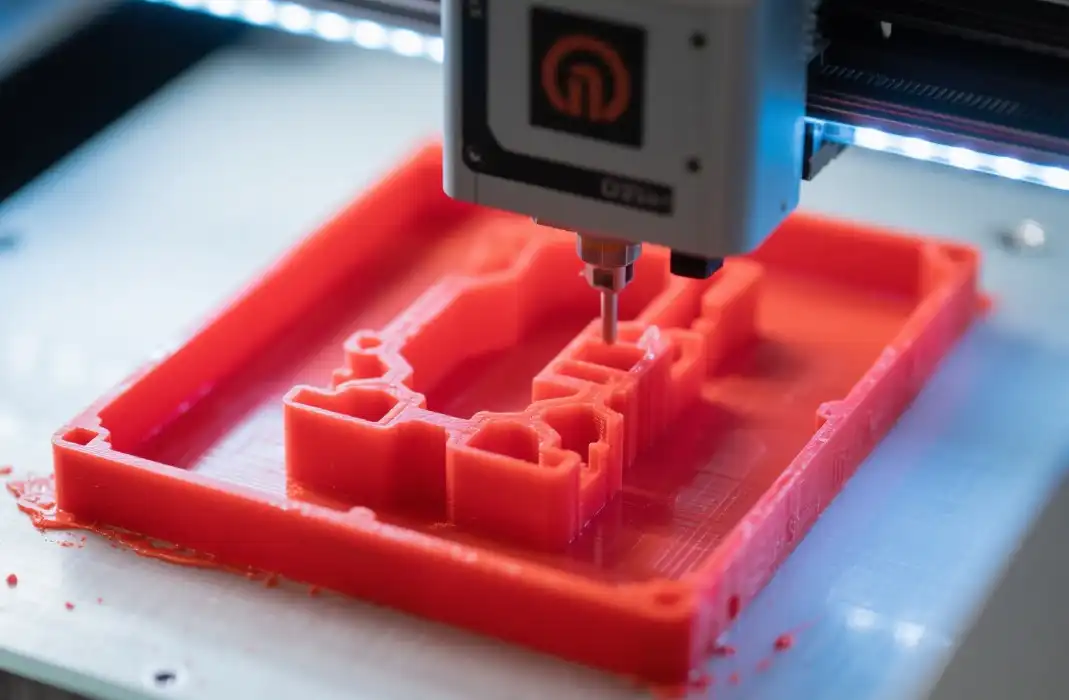

Best Plastic Injection Molding Prices: China vs Germany Comparison

When it comes to plastic injection molding costs, China, by and large, offers essentially lower costs compared to Germany, with investment funds of 30-50% or more conceivable. In any case, Germany exceeds expectations in exactness, quality control, and progressed innovations. The best choice depends on your particular extent of needs, generation volume, quality guidelines, and timeline. For numerous companies, collaborating with a trustworthy Chinese producer like BOEN Model gives an ideal adjust of competitive pricing and solid quality for plastic injection molding services.

Cost Factors in Plastic Injection Molding

Labor Costs

One of the greatest reasons China can offer lower injection molding costs is the considerable difference in labor costs compared to Germany. Fabricating compensation in China is ordinarily as it were one-quarter to one-third of that in Germany, giving Chinese production lines a major fetched advantage. This wage crevice gets to be indeed more noteworthy for labor-intensive forms such as auxiliary wrapping up, assembly, or manual quality checks. As a result, Chinese providers can give exceedingly competitive citations while still keeping up proficient generation operations and productivity, making them an appealing choice for cost-sensitive projects.

Raw Material Costs

China habitually appreciates lower crude material costs for plastics, additives, and other basic inputs utilized in plastic injection molding. The country’s enormous manufacturing environment bolsters large-scale acquiring and optimized supply chains, resulting in a decrease in general fabric estimating. In addition, China produces numerous polymer gums locally, permitting producers to maintain a strategic distance from tall purport obligations and expensive transportation costs. Germany, by differentiate, frequently depends more intensely on imported materials, which can raise production costs. These fabrics taken a toll contrasts altogether affect add up to venture estimating, giving Chinese providers a reliable edge in cost-effective manufacturing.

Operational Costs

Operational expenses—including office rentals, utilities, upkeep, and common overhead—are regularly much lower in China than in Germany. Chinese production lines advantage from more reasonable mechanical and genuine domain, lower power rates, and lower-cost administrative necessities. German producers, be that as it may, confront essentially higher energy costs, strict compliance commitments, and, in general, higher living and working costs. These variables increment their fetched structure, making it harder to offer more accurate estimates. By differentiating, Chinese providers can keep operational investing under control, empowering them to keep up with lower manufacturing costs while still ensuring their profit margins.

Quality Considerations in Injection Molding

Precision and Tolerances

German injection molding is broadly recognized for accomplishing especially tight tolerances and conveying exceedingly exact components. Their progressive apparatus, steady process control, and thorough review procedures permit producers to deliver complex parts with negligible deviation, indeed in amazingly demanding applications. Whereas the best Chinese producers like BOEN can meet exactness requirements for most mechanical employments, Germany still keeps up a slight advantage when resistances must be reliably kept up at the outright least edges. In any case, the progress of innovative technologies in China continues to limit this hole, giving dependable accuracy for a wide range of projects.

Material Selection and Processing

Both Germany and China offer broad choices when it comes to plastic injection molding materials, extending from standard thermoplastics to more specialized building gums. German producers frequently have more profound involvement in dealing with progressed materials such as Look, PPS, or strengthened polymers, which require strict temperature and handling control. Chinese providers, on the other hand, exceed expectations in productively preparing broadly utilized plastics such as ABS, PP, and PE at profoundly competitive costs. BOEN gives comprehensive mastery over different materials, empowering them to bolster different extents of necessities while adjusting execution, fetched, and manufacturability.

Surface Finish and Aesthetics

German injection molding is known for producing parts with exceptional surface finishes and steady visual quality directly out of the mold. Their accuracy tooling and refined handling strategies make it conceivable to accomplish smooth surfaces and stylishly faultless surfaces without extra steps. Whereas driving Chinese producers can deliver comparable results, certain applications may require additional cleaning or post-processing to reach the same level of refinement. BOEN leverages progressive hardware, optimized molding parameters, and experienced professionals to guarantee high-quality surface wraps that meet or surpass desires for most mechanical and consumer-grade applications.

Choosing the Right Injection Molding Partner

Production Volume Considerations

For high-volume generation runs, Chinese injection molding frequently gives the most cost-effective arrangement due to considerable investment funds in labor, tooling, and operational costs. These benefits ended up indeed more articulated as generation scale increments, making China an alluring choice for expansive fabricating prerequisites. German producers, by differentiation, may be more appropriate for smaller generation runs where their computerization, exactness, and effective forms offer assistance balanced by higher costs. BOEN underpins both ends of the range, advertising fast prototyping capabilities as well as solid high-volume fabricating, guaranteeing adaptability for clients with assorted generation needs.

Lead Times and Delivery

Chinese plastic injection molding providers ordinarily provide quicker turnaround times, especially for large production orders, thanks to their broad production line capacities and streamlined workflows. Their capacity to scale rapidly permits ventures to advance from plan to fabricating with negligible delays. German lead times, whereas some of the longer, reflect their nitty-gritty quality methods and constrained capacity. Be that as it may, companies must moreover consider shipping time when sourcing from China, as coordination length can mostly balance the generation speed advantage depending on the target advertise. Assessing both generation time and travel time is fundamental for precise scheduling.

Communication and Project Management

Working with German injection molders may give smoother communication for European businesses due to shared time zones and social recognition. In any case, driving Chinese producers like BOEN have made noteworthy speculations in English-speaking venture supervisors, engineers, and client bolster groups to guarantee proficient collaboration. These companies, moreover, utilize advanced communication platforms, advanced venture tracking tools, and clear documentation forms to minimize mistaken assumptions. As a result, dialect boundaries and time zone contrasts have ended up distant less significant, permitting universal clients to work confidently with Chinese providers all through each arrange of the entire production cycle.

Conclusion

While German injection molding keeps up a notoriety for premium quality, Chinese producers presently offer comparable capabilities at essentially lower costs for numerous applications. By carefully assessing your particular venture prerequisites and joining forces with a trusted provider like BOEN Model, you can leverage China's taken a toll focal points without compromising on quality. BOEN combines competitive estimating with exacting quality control, progressive gear, and experienced engineers to provide extraordinary value in plastic injection molding services.

FAQs

Is Chinese injection molding quality comparable to German quality?

Top Chinese manufacturers can match German quality for most applications, though Germany may have an edge for extremely precise or specialized parts.

How much can I save with Chinese injection molding?

Savings typically range from 30-50% or more compared to German pricing, depending on the project specifics.

What are the main advantages of working with BOEN for injection molding?

BOEN offers competitive pricing, diverse material expertise, fast turnaround times, and excellent English communication, combining the best of Chinese cost-efficiency with international quality standards.

Partner with BOEN for Cost-Effective, High-Quality Injection Molding | BOEN

BOEN Prototype is your ideal partner for plastic injection molding services, offering the perfect balance of competitive Chinese pricing and world-class quality. As a leading injection molding supplier and manufacturer, we provide end-to-end solutions from prototyping to high-volume production. Our state-of-the-art facility, ISO 9001:2015 certification, and experienced engineers ensure superior results for your most demanding projects. Contact us today at contact@boenrapid.com to discuss your injection molding needs and receive a free quote!

References

Zhang, L., & Wang, X. (2021). Comparative analysis of injection molding industries in China and Germany. Journal of Manufacturing Technology Management, 32(3), 512-529.

Schmidt, M., et al. (2020). Quality control standards in plastic injection molding: A global perspective. International Journal of Production Research, 58(14), 4237-4252.

Li, Y., & Chen, J. (2019). Cost-benefit analysis of outsourcing injection molding to China versus domestic production. Journal of Operations Management, 65(6), 591-612.

Müller, A., & Weber, T. (2022). Advances in high-precision injection molding: A review of German manufacturing techniques. Polymer Engineering & Science, 62(5), 1123-1142.

Wang, H., et al. (2021). Comparison of injection molding capabilities between emerging Chinese manufacturers and established European firms. Journal of Cleaner Production, 289, 125721.

Brown, R. (2023). Global trends in plastic injection molding: Market analysis and future projections. Plastics Technology, 69(4), 32-41.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.