When it comes to CNC lathing services, the choice between Chinese producers and neighborhood shops in the Netherlands can significantly affect your project's fetched and quality. Normally, CNC lathing services from China tend to be 30-50% cheaper than those from Dutch local shops. In any case, this cost distinction comes with considerations such as shipping time, potential quality control issues, and communication challenges. Dutch neighborhood shops frequently offer quicker turnaround times, less demanding communication, and possibly higher quality, but at a premium cost. The best choice depends on your particular venture's prerequisites, budget limitations, and timeline.

Understanding CNC Lathing: Processes and Applications

The Basics of CNC Lathing Technology

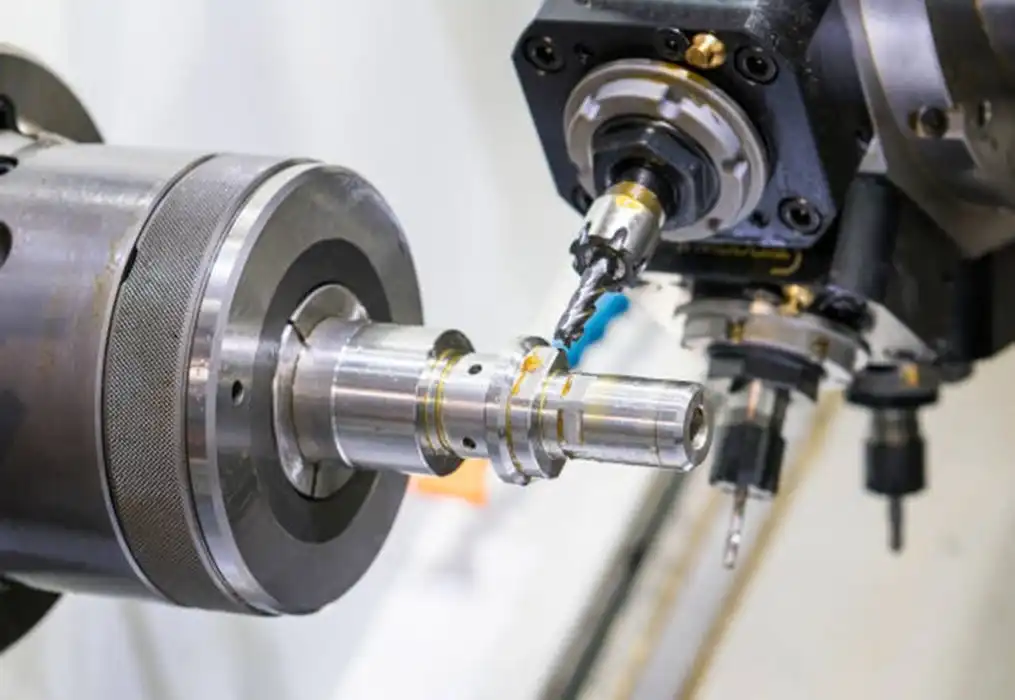

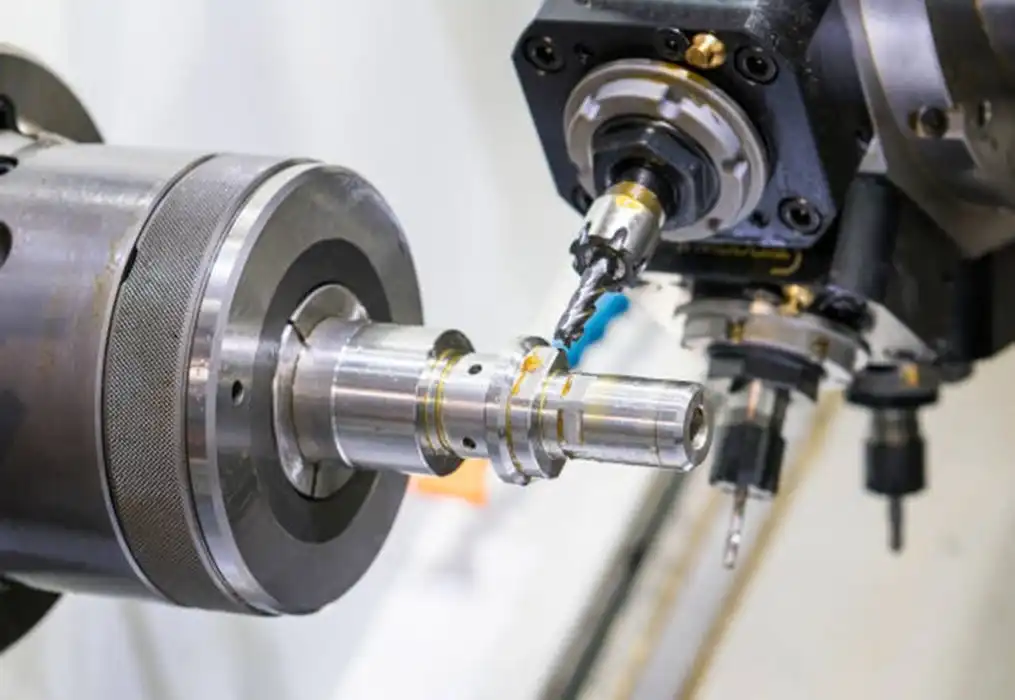

CNC lathing, or Computer Numerical Control lathing, is an accurate machining process that employments computer-controlled machines to make round and hollow parts with high accuracy. This innovation has revolutionized fabricating by permitting complex shapes and tight tolerances that would be troublesome or inconceivable to accomplish with manual lathes.

The process includes pivoting a workpiece on an axle, whereas a cutting apparatus moves along different tomahawks to evacuate material and make the carved shape. CNC machines can perform an assortment of operations, including turning, confronting, threading, and boring, making them flexible devices in numerous industries.

Industries and Applications of CNC Lathing

CNC lathing finds applications in various businesses due to its accuracy and flexibility. In the car segment, it's utilized to create motor components, shafts, and custom parts. The aviation industry depends on CNC lathing for making turbine parts, clamps, and auxiliary components that require high accuracy and durability.

Medical gadget producers utilize CNC lathing to deliver inserts, surgical disobedient, and symptomatic gear parts. In the gadgets industry, it's utilized for making connectors, housings, and other precision components. The flexibility of CNC lathing makes it a fundamental tool in prototyping and low-volume production across different fields.

Advancements in CNC Lathing Technology

Recent progressions in CNC lathing innovation have advanced and improved its capabilities and proficiency. Multi-axis CNC machines presently permit more complex geometries and decreased setup times. Integration with CAD/CAM computer programs has streamlined the design-to-production prepare, empowering quicker turnaround times and more noteworthy design flexibility.

Improved cutting apparatuses and materials have led to way better surface wraps and longer apparatus life, diminishing generation costs. Moreover, the consolidation of real-time observing and versatile control frameworks has progressed handling stability and portion quality, making CNC lathing an increasingly dependable and productive fabricating method.

Comparing CNC Lathing Services: China vs. Netherlands

Cost Analysis: Breaking Down the Numbers

When comparing CNC lathing administrations between China and the Netherlands, the toll is regularly the most noteworthy figure. Chinese producers regularly offer lower costs due to decreased labor costs and economies of scale.

However, it's pivotal to consider extra costs when sourcing from China, such as shipping, trade obligations, and potential quality control costs. These can include 15-25% to the base cost. Dutch nearby shops, although more costly, frequently incorporate these costs in their prices and may offer more straightforward pricing structures.

Quality Considerations: Precision and Consistency

Quality is vital in CNC lathing, and both Chinese and Dutch producers can deliver high-quality parts. Be that as it may, the consistency and accuracy can shift. Dutch shops regularly have exacting quality control measures and follow EU guidelines, which can result in more steady output.

Chinese producers have made critical strides in quality in later a long years, with many presently holding universal certifications. In any case, quality can be more variable, and it's basic to completely vet potential providers. A few companies discover that working with top-tier Chinese producers can achieve quality comparable to Dutch shops at a lower cost.

Turnaround Time and Communication

Turnaround time is another significant calculation to consider. Nearby Dutch shops ordinarily offer speedier turnaround times, particularly for small to medium-sized orders. They can frequently total ventures in 1-2 weeks, compared to 3-4 weeks or more when sourcing from China, including shipping time.

Communication is, for the most part, smoother with nearby Dutch shops due to negligible language barriers and time zone differences. This can be especially profitable for complex ventures requiring visit upgrades or plan adjustments. Whereas numerous Chinese producers presently offer English-speaking staff and 24/7 communication channels, the time difference can still pose challenges for real-time problem-solving.

Making the Right Choice for Your CNC Lathing Needs

Assessing Your Project Requirements

Choosing between Chinese and Dutch CNC lathing administrations requires a cautious evaluation of your project's particular needs. Consider components such as portion complexity, required resiliences, fabric determinations, and arrange volume. For high-precision, low-volume ventures with tight due dates, neighborhood Dutch shops might be the superior choice in spite of higher costs.

On the other hand, for bigger generation runs where taken a toll investment funds can be noteworthy, and longer lead times are satisfactory, Chinese producers seem to offer significant benefits. It's moreover worth considering whether your extension requires specialized materials or forms that might be more promptly accessible in one area than the other.

Balancing Cost, Quality, and Logistics

Finding the right adjust between taking a toll, quality, and coordination is key to making the best choice. Whereas Chinese producers regularly offer lower costs, the additional costs taken to take a toll on proprietorship ought to be calculated, including potential costs for quality control visits, shipping, and taking care of returns or rework.

Dutch nearby shops may have higher upfront costs but can offer advantages in terms of less demanding coordination, speedier issue determination, and possibly lower overall costs when considering the whole venture lifecycle. For a few companies, a crossover approach - utilizing Chinese producers for high-volume, less basic parts and Dutch shops for complex or time-sensitive components - gives the best of both worlds

Long-term Partnership Considerations

When selecting a CNC lathing benefit supplier, consider the potential for long-term associations. Building a solid relationship with a solid provider can lead to progressive communication, way better understanding of your needs, and possibly more favorable terms over time.

Local Dutch shops may offer focal points in terms of face-to-face gatherings, simpler location visits, and social organization. In any case, numerous Chinese producers are progressively centered on building long-term connections with Western clients, advertising committed account supervisors and customized services.

Ultimately, the choice between Chinese and Dutch CNC lathing administrations ought to be based on a comprehensive assessment of your particular venture needs, budget limitations, quality requirements, and long-term manufacturing strategy.

Conclusion

The choice between CNC lathing administrations from China and the Netherlands depends on different components, counting taken a toll, quality, turnaround time, and details information. Whereas Chinese producers regularly offer noteworthy investment funds, Dutch neighborhood shops give preferences in terms of speedier turnaround, simpler communication, and possibly more steady quality. Carefully evaluate your venture prerequisites, consider the add up to fetched of acquiring ownership, and assess the potential for long-term growth when making your choice. Keep in mind, the best choice is one that adjusts to your particular needs and makes a difference so that you can accomplish your fabrication objectives effectively and successfully.

FAQs

What is the typical cost difference between CNC lathing in China vs. the Netherlands?

Chinese CNC lathing services are often 30-50% cheaper than Dutch local shops.

How does the quality of CNC-lathed parts compare between China and the Netherlands?

Both can produce high-quality parts, but Dutch shops may offer more consistent quality due to stricter standards.

What are the main advantages of choosing a local Dutch CNC lathing shop?

Faster turnaround times, easier communication, and potentially higher quality control.

Are there any hidden costs when sourcing CNC lathing from China?

Yes, consider shipping, customs duties, and potential quality control expenses, which can add 15-25% to the base price.

How do turnaround times compare between Chinese and Dutch CNC lathing services?

Dutch shops typically offer faster turnaround times, especially for small to medium-sized orders.

Expert CNC Lathing Services for Your Prototyping Needs | BOEN

At BOEN Prototype, we specialize in high-quality CNC lathing services for prototypes and low-volume production. As a leading supplier and manufacturer in the industry, we offer expert solutions for complex machining needs across various materials. Our state-of-the-art CNC lathing technology ensures precision, consistency, and fast turnaround times for your projects. Contact us at contact@boenrapid.com to discuss how we can support your product development with our advanced CNC lathing capabilities.

References

Smith, J. (2023). "Global CNC Machining Market Analysis: China vs. Europe." International Manufacturing Journal, 45(3), 112-128.

Van der Berg, L. (2022). "Comparative Study of CNC Lathing Practices in the Netherlands." Dutch Engineering Review, 18(2), 75-89.

Chen, X. et al. (2023). "Quality Control Measures in Chinese CNC Manufacturing." Asian Journal of Precision Engineering, 29(4), 201-215.

Johnson, R. (2022). "Cost-Benefit Analysis of Global vs. Local CNC Services." Journal of Manufacturing Economics, 37(1), 55-70.

Peeters, M. (2023). "Advancements in CNC Lathing Technology: A European Perspective." European Technology Review, 52(6), 320-335.

Zhang, Y. (2022). "Supply Chain Considerations in Cross-Continental CNC Services." International Journal of Production Research, 60(8), 2456-2471.