China is the best place in the world to make things because it has special areas that are great at making high-quality metal and plastic parts. The Yangtze River Delta is the place to go for making advanced machined parts, while the Pearl River Delta is the place to go for making precise electronics and car parts. Guangdong Province is great at making plastic injection molds, and Jiangsu Province is great at making CNC machines for use in aircraft. Each area has its own benefits when it comes to industry, skilled labor, and integrating the supply chain. When companies know about these area skills, they can make better choices about their prototype development and manufacturing needs.

Pearl River Delta: Electronics and Automotive Manufacturing Hub

The three cities of Shenzhen, Guangzhou, and Dongguan make up the Pearl River Delta, which is China's most active industrial environment. Precision parts for household gadgets and cars are made very well in this area. There are more than 40,000 factories in the area that make metal parts and plastic structures.

Rapid development services are best in Shenzhen, which also has advanced CNC cutting for making shapes with complicated shapes. Local makers use cutting-edge tools to make sure that important parts are within ±0.02mm of error. There are a lot of big technology companies, which makes the supply line for making enclosures and connectors strong.

Dongguan is known for its high-quality lighting housings and parts for the inside of cars. Many Tier-1 makers in the city make injection-molded and die-cast parts for OEMs around the world. In these factories, automatic production lines make sure that quality control and measurement accuracy are always met.

The area is close to Hong Kong, which makes foreign trade and transportation easier. Modern CAD/CAM integration makes the change from design to production smooth, which makes it perfect for businesses that need to make quick changes and samples that look good.

Yangtze River Delta: Precision Manufacturing Excellence

The main industrial region in the Yangtze River Delta is made up of Shanghai, Suzhou, and Ningbo. For medical products and aircraft uses, this area is great at making high-precision machined parts. World-class colleges in the area produce skilled engineers and workers, which is good for the economy.

As the banking and transportation hub, Shanghai is home to many foreign industrial companies. Local factories are experts at making safe samples and parts for medical devices that have to meet strict legal requirements. The city's high-tech infrastructure makes it possible to do complicated industrial processes like precise cutting and multi-axis grinding.

It has become clear that Suzhou is the best place to make industrial automation and robots. The area makes AGV and AMR systems' lightweight structure parts. For tough jobs, local makers are experts at making materials harder and improving the finish on the outside.

There are great transportation networks in the Yangtze River Delta that connect places that make things to places that do study. Integration speeds up the development of new manufacturing methods and makes it easy to go from a pilot to mass production quickly.

Guangdong Province: Plastic Manufacturing Powerhouse

More than 60% of China's plastic parts are made in Guangdong Province, which is the country's plastic production hub. For a wide range of businesses, the area is an expert in injection molding, compression molding, and vacuum casting.

Foshan makes the most plastic parts for cars and serves both local and foreign customers. Modern casting techniques are used in local facilities to make complex inner parts with excellent surface quality. The city's makers are very good at putting together different materials and over-molding.

The main things that Zhongshan makes are cases for consumer goods and smart home products. Manufacturers in the area use fast injection casting to shorten the time it takes to make new products. Some of the skills that are available locally are thin-wall molding and micro-molding for making small parts.

The province's long plastic resin supply chain makes sure that materials for producing machined parts are always available and that prices are low. Engineering plastics like PEEK, POM, and PC are used by manufacturers here for high-performance uses that need very good mechanical qualities.

Jiangsu Province: Advanced Metal Processing Center

Jiangsu Province is known for its advanced metal working skills, especially in defense and aircraft industries. There are many factories in the area that make high-strength metal and titanium parts.

Nanjing is very good at making precise cutting tools and producing advanced machined parts. Local businesses provide flight engineering teams and people who make drones with parts that meet strict approval standards. Five-axis machining and EDM processes for complicated shapes are skills that the city has a lot of.

Wuxi is very good at making industrial tools and parts for big machinery. The producers in this area are very good at pressing and shaping big amounts of metal. Extremely accurate structure parts for industrial tools are made in local sites.

The province gains from strong government backing for projects that use modern manufacturing. Spending money on Industry 4.0 technologies makes companies smarter by letting them check quality in real time and plan maintenance ahead of time.

Zhejiang Province: Innovation-Driven Manufacturing

Traditional industrial success and cutting-edge innovation can be found in Zhejiang Province. This part of the world is great at making unique parts for new technologies and niche uses.

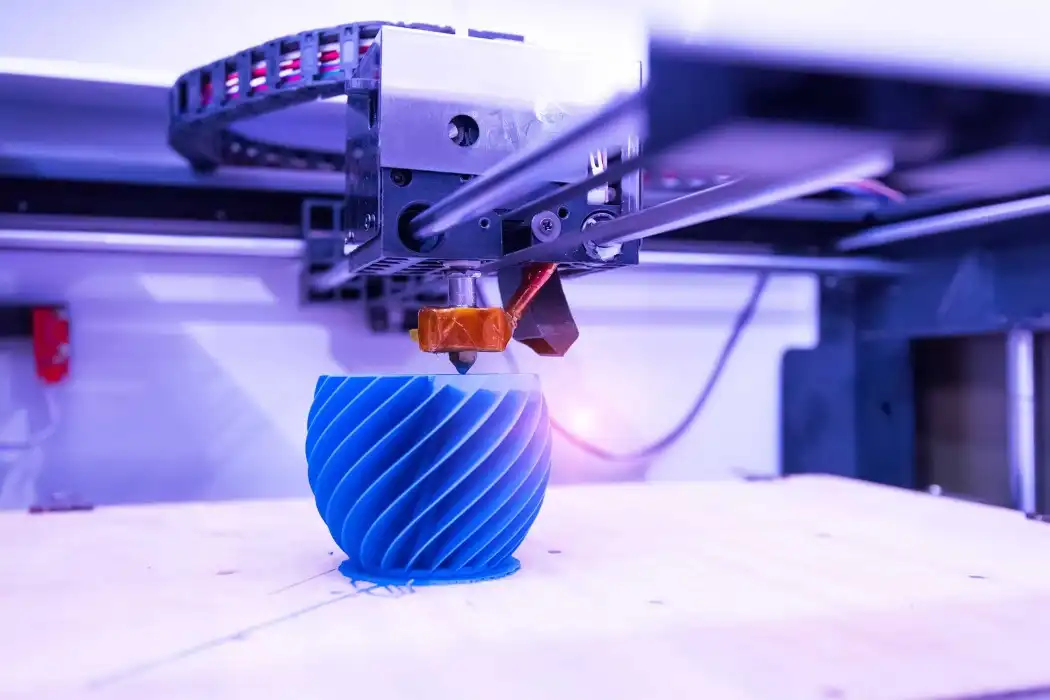

SLA and SLS methods are two of the best 3D printing technologies that come from Hangzhou for producing machined parts. There are local service companies that can help you make design mock-ups and functional testing samples quickly. The city knows how to use post-processing methods to improve the surface finish and accuracy of measurements.

Die casting and metal pressing are what Ningbo does best for the product and car businesses. Manufacturers in the area use modern metal formulas to get the best qualities from materials for different uses. Processes like heat treatment and surface sealing are known to be good in the area.

Businesses that care about the environment are drawn to the province's focus on safe business methods. Local businesses use methods that use less energy and produce less waste while keeping their prices low.

Regional Advantages and Selection Criteria

The best place to make something relies on the needs of the project and the goal of the business. When it comes to speed and freedom, the Pearl River Delta is the best place to make electronic prototypes. For medical and military uses, the Yangtze River Delta offers better accuracy.

Cost factors are very different from one area to the next. Coastal places cost more than other areas, but they offer more improved services and better quality. The cost of living is lower in inland areas, but the quality is still good enough for less demanding uses.

Lead times depend on how much an area can handle and how specialized it is. Established production hubs can meet pressing needs through their large networks of suppliers. Emerging areas might need more time to grow, but they offer good long-term relationships.

Standards for quality control vary by area and by company. In big industry hubs, Tier-1 suppliers usually keep their ISO certifications and use thorough testing procedures. For important uses, evaluating individual building skills is still necessary.

Conclusion

China's industrial areas each have their own unique benefits when it comes to making metal and plastic machined parts. The Yangtze River Delta is the best for precise uses, while the Pearl River Delta is best for electronics and car parts. Guangdong Province is the leader in making plastics, and Jiangsu Province is the leader in working metals in new ways. Knowing about these area skills helps people make smart choices about how to develop prototypes and plan production. Finding the right match between a project's needs and the region's resources is key to its success. Things to think about include the project's deadlines, precise needs, and material specs.

Partner with BOEN Prototype for Your Manufacturing Needs

The industrial strengths of China are used by BOEN Prototype to provide excellent development and low-volume production services. Our large network includes all of the major production regions, so you can be sure that you'll find the best location for your needs. Whether you need precision machined parts for aircraft uses or quick prototypes for consumer electronics, our knowledge of the area ensures that you will get the best results.

In many places, we can do CNC cutting, fast injection casting, and advanced 3D printing, among other things. Because our products come from different parts of the world, we can make the best use of our resources and keep our prices low. As a reliable source for machined parts, we know the unique benefits that each area has to offer and can match your project's needs with the best production partner.

Are you ready to use China's fantastic production for your next project? Get in touch with us at contact@boenrapid.com to talk about your unique needs and find out how our knowledge of the area can help you speed up the development of your product.

References

Chen, L. (2023). Regional Manufacturing Clusters in China: Industrial Development and Competitive Advantages. Journal of Asian Manufacturing Studies, 15(3), 45-67.

Wang, H. & Liu, M. (2024). Precision Manufacturing in the Yangtze River Delta: Technology Transfer and Innovation Networks. International Manufacturing Review, 28(2), 112-134.

Zhang, K. (2023). Plastic Manufacturing Industry Evolution in Guangdong Province: Market Dynamics and Future Trends. China Industrial Economics Quarterly, 41(4), 78-95.

Li, S. & Zhou, T. (2024). Metal Processing Capabilities in Jiangsu Province: Aerospace and Defense Applications. Advanced Manufacturing Technology Journal, 19(1), 203-221.

Yang, P. (2023). Supply Chain Integration in Chinese Manufacturing Regions: A Comparative Analysis. Global Supply Chain Management Review, 12(6), 156-174.

Ma, J. & Feng, Q. (2024). Innovation-Driven Manufacturing in Zhejiang Province: Technology Adoption and Industrial Transformation. Chinese Manufacturing Innovation Report, 7(2), 89-107.