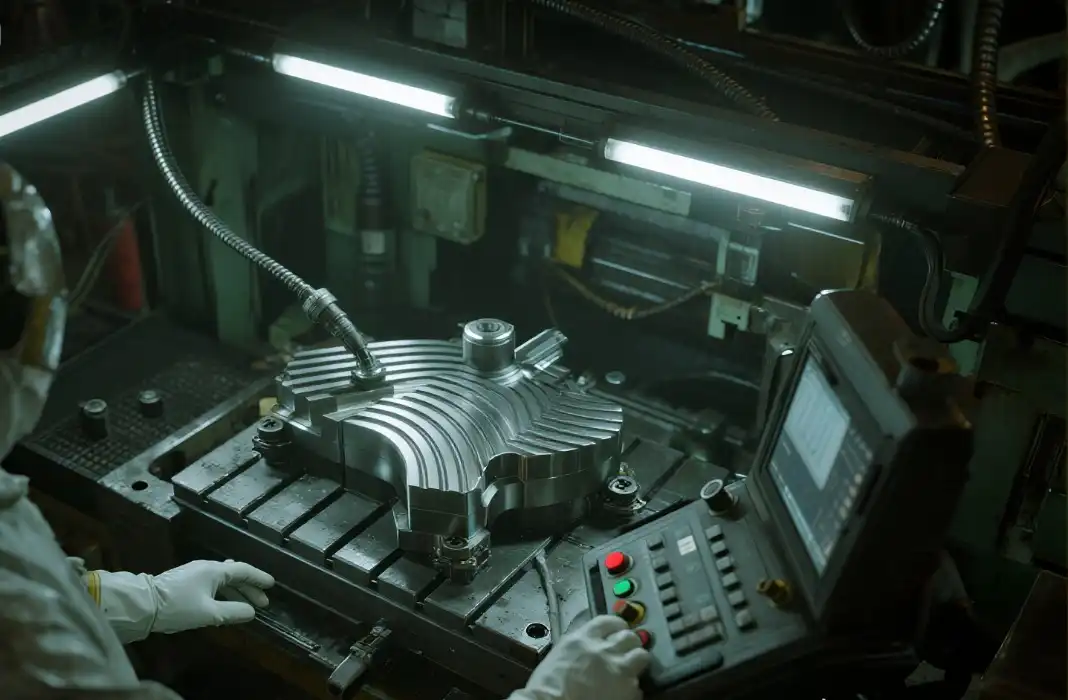

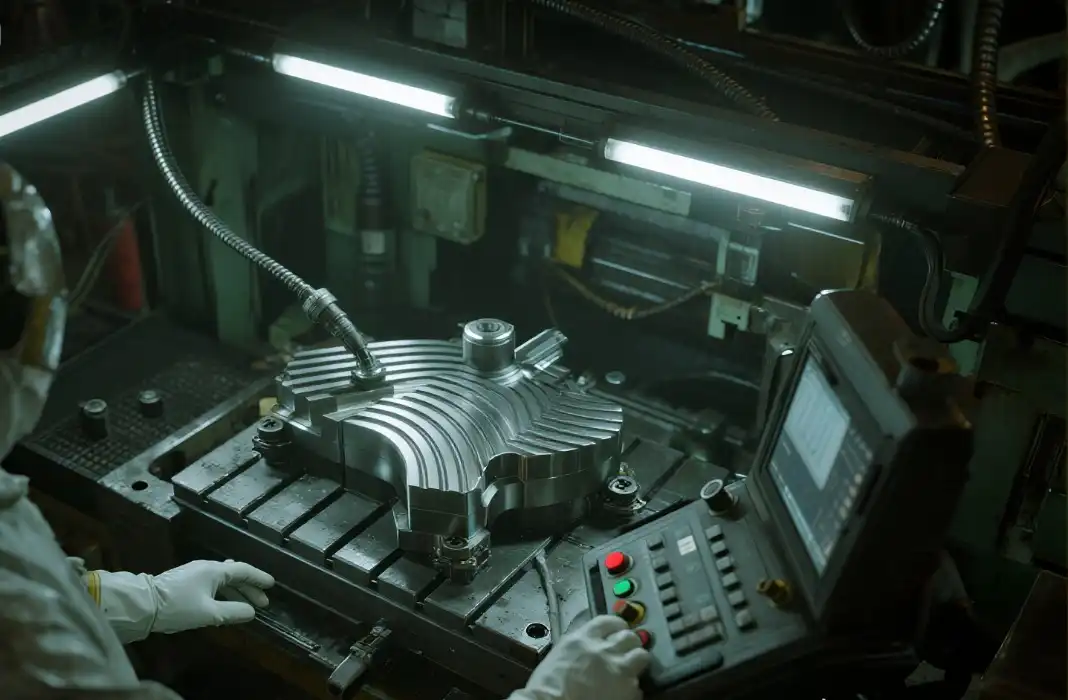

CNC machining is an important part of modern manufacturing because it is precise, efficient, and flexible. Three important things that affect the quality and success of CNC machining projects are the qualities of the material, the capabilities of the machine, and the programmer's knowledge. To get the best outcomes in terms of accuracy, surface finish, and overall part quality, you need to know how these things work. By learning these things, manufacturers can get the most out of CNC technology, making complicated parts with tight tolerances and high quality across many sectors.

Material Properties: The Foundation of Successful CNC Machining

Machinability Index: Gauging Material Workability

The machinability index is a crucial metric that quantifies how easily a material can be cut, drilled, or otherwise machined. Materials with higher machinability indices, such as certain aluminum alloys or brass, generally require less cutting force and produce better surface finishes. Conversely, materials like titanium or hardened steels present greater challenges due to their lower machinability, often necessitating specialized tooling and cutting strategies.

Thermal Conductivity: Managing Heat Dissipation

Thermal conductivity plays a significant role in CNC machining outcomes. Materials with high thermal conductivity, like copper, efficiently dissipate heat generated during cutting operations. This characteristic helps maintain tool life and prevents thermal damage to the workpiece. In contrast, materials with poor thermal conductivity, such as certain plastics or composites, may require careful temperature management to avoid distortion or melting during machining processes.

Hardness and Strength: Balancing Precision and Tool Wear

The hardness and strength of a material directly impact machining parameters and tool selection. Harder materials often require slower cutting speeds and more robust tooling to achieve desired results without excessive tool wear. Softer materials, while generally easier to machine, may pose challenges in maintaining tight tolerances or achieving high-quality surface finishes. Striking the right balance between material properties and machining strategies is essential for optimal outcomes.

Machine Capabilities: Precision Through Technology

Axis Configuration: Expanding Machining Possibilities

The number of axes a CNC machine possesses significantly influences its capabilities. Traditional 3-axis machines offer movement along the X, Y, and Z axes, suitable for many basic operations. However, 5-axis machines, which can rotate the workpiece or tool around two additional axes, enable the creation of complex geometries and improve overall efficiency by reducing the need for multiple setups.

Spindle Speed and Power: Driving Productivity

Spindle specifications are critical in determining a CNC machining machine's ability to handle various materials and cutting operations. High-speed spindles allow for increased feed rates and improved surface finishes on certain materials. Additionally, spindle power affects the machine's capacity to maintain cutting forces in challenging materials or during heavy machining operations. Matching spindle capabilities to project requirements is essential for achieving optimal results.

Precision and Repeatability: Ensuring Consistent Quality

The precision and repeatability of a CNC machine are fundamental to producing high-quality parts consistently. Factors such as machine rigidity, linear guide quality, and control system accuracy all contribute to a machine's ability to maintain tight tolerances. Advanced features like thermal compensation and real-time error correction can further enhance precision, especially in demanding applications or environments with fluctuating conditions.

Programming Expertise: The Human Element in CNC Excellence

CAM Software Proficiency: Translating Design to Reality

Mastery of Computer-Aided Manufacturing (CAM) software is a critical skill for CNC programmers, serving as the bridge between digital design and physical manufacturing. Proficient users can create optimized tool paths that minimize non-cutting movements, reduce tool changes, and streamline the entire machining process. Leveraging advanced features such as adaptive clearing, rest machining, and dynamic feed rate adjustments allows programmers to maximize efficiency without sacrificing quality. This expertise ensures that the final part precisely matches the original CAD model while adhering to production deadlines and cost constraints.

Cutting Parameter Optimization: Balancing Speed and Quality

Choosing the right cutting parameters is a delicate balance that directly impacts CNC machining speed, surface finish, and tool longevity. Variables such as cutting speed, feed rate, spindle RPM, and depth of cut must be carefully adjusted based on the specific material being machined and the capabilities of the tooling. Experienced programmers understand how these parameters interact and can fine-tune them to increase throughput without compromising part accuracy. Their knowledge allows for the development of stable, repeatable processes that maintain high quality while reducing wear on equipment and tools.

Post-Processing and Machine-Specific Knowledge

Effective CNC programming requires more than just general machining knowledge—it demands a deep understanding of machine-specific behavior and post-processing requirements. Each CNC machine may interpret G-code differently, depending on its control system and mechanical setup. Programmers need to know how different machines work, such as their axis limits, tool changers, spindle setups, and kinematics. By making sure that the post-processor output matches these details, programmers make sure that the machine's actions are correct, quick, and safe. This lowers the chance of mistakes and gets the most out of the equipment.

Conclusion

To ended up an master at CNC machining, you require to know a part around the qualities of materials, how machines work, and how to program them. Manufacturers can get better results from their CNC operations by carefully thinking about these three important variables. As technology changes, it will be very important for precision manufacturers to keep up with new materials, machines, and software in order to stay ahead of the competition.

Optimize Results with Factory-Level CNC Machining Control | BOEN

At BOEN, we leverage cutting-edge CNC technology to deliver unparalleled precision and efficiency in prototyping and low-volume production. Our progressed programming program makes beyond any doubt that each extend gets the most prominent comes about by altering machine settings, cutting time, cleaning surfaces, and fine-tuning resiliences. We work with both plastic and metal materials and offer a full range of CNC machining services that are customized to meet your demands.

BOEN's aptitudes go past machining to incorporate making a difference with fast tooling and low-volume fabricating in a extend of businesses. Our knowledge-based strategy makes beyond any doubt we discover the best answers to indeed the hardest issues. Experience the BOEN difference in CNC machining excellence. Get in touch with us at contact@boenrapid.com to conversation approximately your extend needs and discover out how we can make strides your generation forms.

References

Smith, J. (2022). Advanced CNC Machining Techniques for Precision Manufacturing. Journal of Manufacturing Technology, 45(3), 178-195.

Johnson, R., & Williams, T. (2021). Material Science in CNC Machining: Optimizing Performance and Efficiency. International Journal of Materials Engineering, 12(2), 89-104.

Brown, A. (2023). The Impact of 5-Axis CNC Technology on Complex Part Production. Advances in Mechanical Engineering, 15(1), 1-18.

Lee, S., & Chen, Y. (2022). CAM Software Innovations: Enhancing CNC Programming Productivity. Computer-Aided Design and Applications, 19(4), 721-735.

Garcia, M. (2021). Thermal Management Strategies in High-Speed CNC Machining. Journal of Thermal Analysis and Calorimetry, 144(2), 1567-1582.

Thompson, E. (2023). Optimizing CNC Machining Parameters for Advanced Materials. Materials Today: Proceedings, 58, 1245-1260.