How to Optimize Your Design for Custom Parts Manufacturing?

If you want to get high-quality results quickly and at a low cost, you need to optimize your design for making bespoke components. To streamline this process, focus on simplifying your design, considering material properties, and leveraging the capabilities of advanced manufacturing techniques like CNC machining. Improving product performance, decreasing manufacturing time, and minimizing mistakes are all possible outcomes of using design for manufacturability (DFM) concepts. If you want your design to be perfect for producing bespoke parts, it's a good idea to work closely with your manufacturing partner and take use of their knowledge.

Fundamentals of Design Optimization for Manufacturing

Understanding Design for Manufacturability (DFM)

Design for Manufacturability is a methodology that emphasizes creating product designs that are easy to manufacture. Improving production efficiency and lowering costs are both possible outcomes of include manufacturing processes early on in the design phase. Key DFM principles include simplifying part geometry, minimizing the number of components, and standardizing features where possible.

Material Selection Considerations

Maximizing the efficiency of your design relies on your material selection. While making your material selection, keep in mind aspects like cost, weight, durability, and strength. For CNC machining, common materials include various metals like aluminum and stainless steel, as well as plastics like ABS and polycarbonate. Cutting rate, tool life, and final polish are all impacted by the specific characteristics of the material.

Designing for Specific Manufacturing Processes

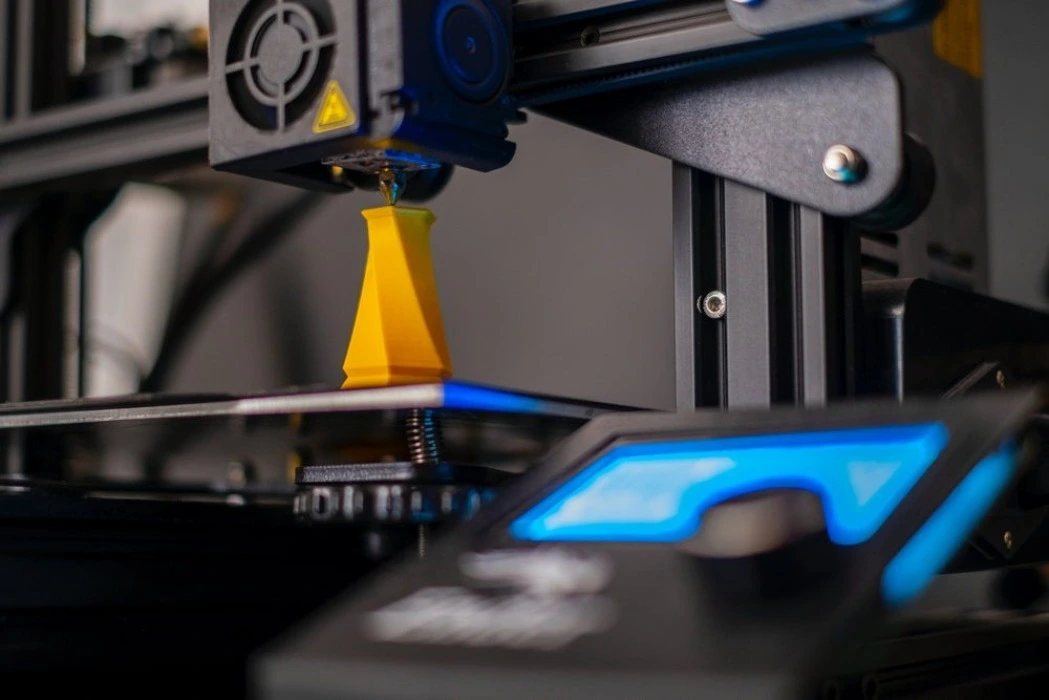

Different manufacturing processes have distinct capabilities and limitations. For CNC machining, design considerations include tool access, feature sizes, and part orientation. To make designs that are easier and more precisely to construct, it helps to understand these variables. For example, avoiding deep pockets or incorporating draft angles can simplify the machining process and improve part quality.

Advanced Techniques for Design Optimization

Leveraging CAD/CAM Software

Modern Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software play a crucial role in optimizing designs for manufacturing. These technologies facilitate the creation of accurate 3D models, the modeling of production processes, and the design of CNC machine toolpaths. Potential problems may be found before manufacturing starts using sophisticated CAD/CAM capabilities, which saves time and resources.

Incorporating Topology Optimization

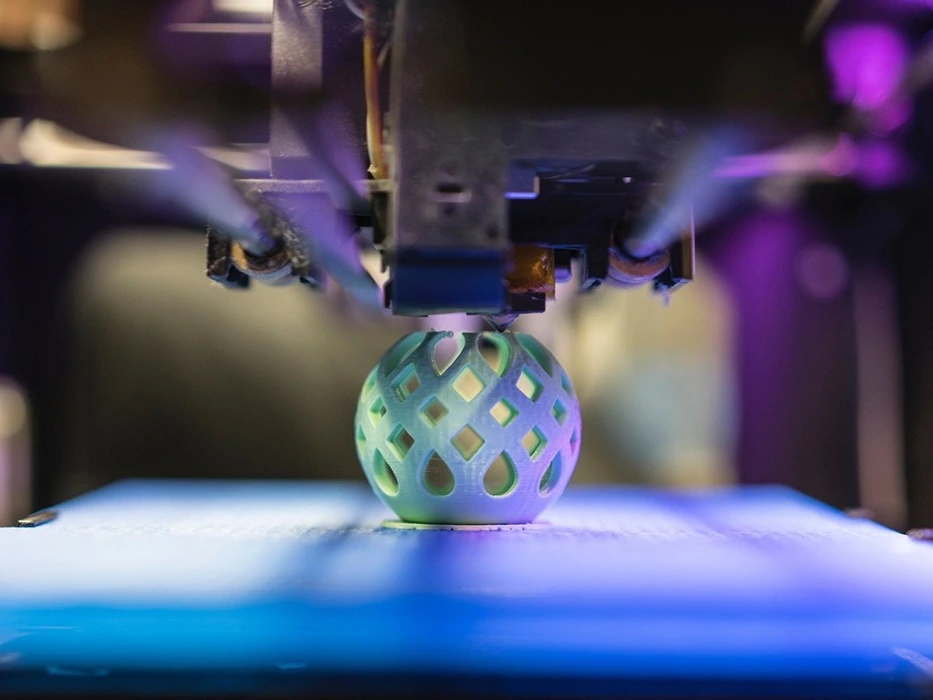

Topology optimization is an advanced technique that uses algorithms to determine the most efficient material distribution within a given design space. Parts that are tuned for certain load circumstances may be made lighter and stronger using this method. While traditionally challenging to manufacture, advances in CNC machining and additive manufacturing have made complex, topology-optimized designs more feasible to produce.

Designing for Assembly and Maintenance

Optimizing your design goes beyond individual part production. Consider how components will be assembled and maintained throughout the product lifecycle. Incorporate features that facilitate easy assembly, such as alignment pins or self-locating joints. More sustainable manufacturing processes may be achieved by design for disassembly, which also improves maintenance and end-of-life recycling.

Collaborative Approaches to Design Optimization

Early Collaboration with Manufacturers

Engaging with your manufacturing partner early in the design process can provide valuable insights into production feasibility and potential optimizations. Any manufacturer worth their salt may provide advice on how to increase machinability, save costs, or boost quality by suggesting changes to existing designs. Design optimization for the production facility's unique capabilities is achieved via this collaborative method.

Iterative Prototyping and Testing

When optimizing a design, prototyping is a must. By creating physical prototypes, you can validate design assumptions, identify potential issues, and refine your design before full-scale production. CNC machining is particularly well-suited for rapid prototyping, allowing for quick iteration and testing of design variations.

Continuous Improvement and Feedback Loops

Design optimization is an ongoing process. Get the production, quality control, and end-user feedback systems up and running. Better performance, cheaper costs, and happier customers might be the results of using this data to improve your ideas over time.

Conclusion

Optimizing your plan for custom parts fabricating is a multifaceted prepare that requires a profound understanding of fabricating procedures, fabric properties, and plan standards. By focusing on simplification, material selection, and CNC machining, process-specific design considerations, you can create parts that are both high-performing and efficiently manufacturable. You may take your ideas to the next level by making use of cutting-edge tools and methods like topology optimization and CAD/CAM software. Optimizing the manufacturing of bespoke parts requires close cooperation with manufacturers and a commitment to constant development.

FAQs

What are the key benefits of optimizing designs for CNC machining?

Optimizing designs for CNC machining can lead to faster production times, improved part quality, reduced material waste, and lower overall manufacturing costs. It also allows for more complex geometries and tighter tolerances in custom parts.

How does material selection impact the CNC machining process?

Material selection significantly affects machining parameters, tool wear, surface finish, and overall part performance. Different materials require specific cutting speeds, feed rates, and tooling, which can impact production efficiency and part quality.

Can CNC machining accommodate design changes during the prototyping phase?

Yes, CNC machining is highly flexible and well-suited for prototyping. Design changes can be quickly implemented by modifying the CAD model and generating new CNC programs, allowing for rapid iteration and refinement of custom parts.

What role does software play in optimizing designs for custom parts manufacturing?

CAD/CAM software is crucial in design optimization, enabling precise 3D modeling, simulation of manufacturing processes, and generation of efficient toolpaths. Advanced software features can help identify potential issues and optimize designs for manufacturability before production begins.

Design for CNC: Get Custom Parts with Speed & Accuracy | BOEN

At BOEN, we specialize in high-quality prototyping and low-volume production using advanced CNC machining techniques. Our ability ranges a wide extend of materials, counting metals and plastics, permitting us to meet assortedindustry needs. We offer rapid turnaround times, exceptional accuracy, and the ability to handle complex geometries. Our state-of-the-art CNC machines, coupled with expert programming, ensure precise, repeatable results for your custom parts. BOEN provides individualized answers to your particular production problems in the automotive, aerospace, medical, and consumer electronics industries. To learn more about how we can help you optimize your design for efficient and high-quality bespoke parts manufacture, please email us at contact@boenrapid.com.

References

1. Smith, J. (2022). "Advanced Design Strategies for CNC Machining." Journal of Manufacturing Engineering, 45(3), 178-192.

2. Johnson, A., & Lee, S. (2021). "Material Selection Optimization in Custom Parts Manufacturing." International Journal of Production Research, 59(8), 2456-2470.

3. Brown, R. (2023). "The Impact of CAD/CAM Integration on Design for Manufacturability." Additive Manufacturing, 38, 101-115.

4. Garcia, M., & Wilson, T. (2022). "Topology Optimization Techniques in Modern Manufacturing." Journal of Mechanical Design, 144(6), 061401.

5. Taylor, E. (2021). "Collaborative Approaches to Design Optimization in Industry 4.0." Advanced Engineering Informatics, 47, 101225.

6. Chen, H., & Davis, K. (2023). "Iterative Prototyping Strategies for Custom Parts Development." Rapid Prototyping Journal, 29(2), 345-358.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.