Key Factors That Affect CNC Turning Costs

CNC turning costs are influenced by several key factors that can significantly impact the final price of manufactured parts. These factors include material selection, part complexity, production volume, surface finish requirements, and CNC machining time. The complexity and expense of raw materials and CNC machining are both impacted by the material choice. Complex geometries often require more sophisticated tooling and longer CNC machining times. Increases in production volume usually result in decreases in per-unit costs due to economies of scale. Depending on the surface finish criteria, further processing steps may be required, which might drive up total prices. Lastly, CNC machining time directly correlates with labor and equipment costs. If you want your CNC turning projects to be successful and your manufacturing solutions to be affordable, you must understand these variables.

Material Selection and Its Impact on CNC Turning Costs

Raw Material Costs and Availability

The CNC turning costs are heavily influenced by the material choice. The total costs for the project might be drastically affected by the different materials' differing prices. For instance, common materials like aluminum and mild steel are generally more affordable compared to specialized alloys or exotic metals. The availability of raw materials also affects costs, as scarce or hard-to-source materials may come with premium prices. Choosing the correct material for your CNC turning project requires careful consideration of the trade-offs between price and material characteristics.

Machinability and Tool Wear

Machinability refers to how easily a material can be cut or shaped using CNC machining processes. Materials with high machinability, such as brass or aluminum, are generally easier to work with and result in lower machining costs. On the other hand, harder materials like titanium or certain stainless steel alloys can be more challenging to machine, requiring specialized tooling and longer processing times. As a result of these issues, tool wear increases, which drives up expenses because of the need to replace tools more often and the possible downtime that comes with doing so.

Material-Specific Processing Requirements

The cost of CNC turning may be impacted by materials that need certain processing conditions or extra procedures. For example, certain metals may need heat treatment before or after machining to achieve desired properties. Others might require specialized coolants or cutting fluids to prevent overheating during the machining process. Additional processing time and the demand for specialist equipment or consumables might drive up the total cost of manufacturing due to material-specific requirements.

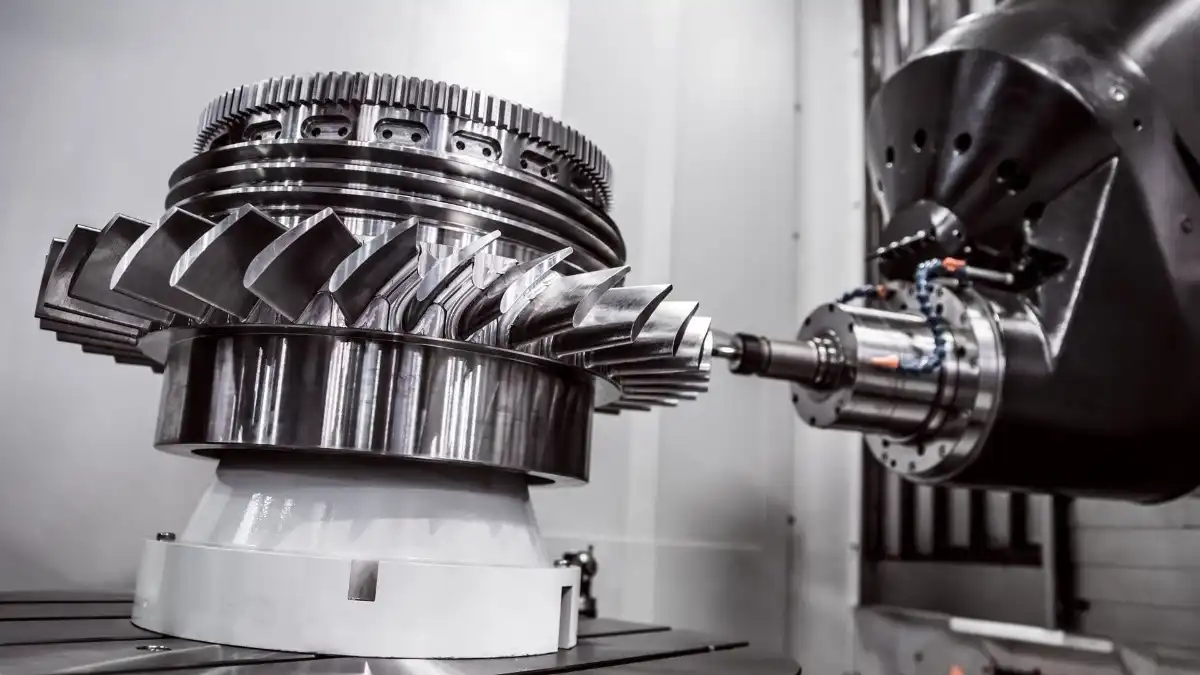

Part Complexity and Design Considerations

Geometric Complexity and Feature Density

The CNC turning costs are heavily influenced by the geometrical complexity of the component. Parts with intricate shapes, multiple features, or tight tolerances often require more sophisticated machining strategies and longer processing times. For instance, components with deep pockets, thin walls, or complex contours may necessitate multiple setups or specialized tooling, increasing both machining time and potential for errors. Additionally, parts with a high density of features in a small area can be more challenging to machine, potentially requiring smaller, more expensive cutting tools and more precise machine control.

Tolerance Requirements and Precision

The level of precision required for a part directly impacts CNC turning costs. Tighter tolerances demand more precise machining operations, which often translate to slower cutting speeds and more frequent tool changes to maintain accuracy. CNC machining high-precision parts may also require additional quality control measures, such as in-process measurements or post-machining inspections, further adding to the overall cost. Looser tolerances may help bring prices down, but you have to weigh those savings against the part's functional needs to make sure it works as it should.

Design for Manufacturability (DFM) Considerations

Implementing Design for Manufacturability principles can significantly impact CNC turning costs. Parts may be made more machinability and less complicated by considering production limitations during design. This might involve simplifying geometries, avoiding unnecessarily tight tolerances where possible, or incorporating features that facilitate easier machining. For example, adding relief cuts or designing parts to minimize the need for tool changes can streamline the manufacturing process and reduce costs. Collaborating with manufacturing experts early in the design phase can help identify cost-saving opportunities without compromising part functionality.

Production Volume and Economies of Scale

Setup Costs and Batch Sizes

The total cost of CNC turning is heavily influenced by setup expenditures, particularly for lower production runs. Tooling, fixture setup, and CNC machine programming all contribute to these expenses. For low-volume production, these setup costs are distributed across fewer parts, resulting in a higher per-unit cost. As production volume increases, the setup costs are spread over more units, effectively reducing the cost per part. Larger batch sizes become more cost-effective when economies of scale are taken into consideration. To minimize overproduction, nevertheless, batch size should be balanced with inventory management and demand forecasts.

Tooling Amortization and Long-Term Cost Considerations

When it comes to CNC machining, specifically CNC turning, specialized tooling or fixtures may be required for certain parts.These instruments may be rather expensive, particularly for components that are complicated or need a high level of accuracy. In low-volume production, these tooling costs can substantially impact the per-unit price. However, as production volume increases, these costs can be amortized over a larger number of parts, reducing the overall cost per unit. For long-term projects or repeat orders, investing in durable, high-quality tooling can lead to cost savings over time, even if the initial investment is higher. When making judgments concerning tooling investments, it is vital to consider the estimated lifetime production volume.

Production Efficiency and Learning Curve Effects

As production volume increases, CNC turning operations often become more efficient due to the learning curve effect. Reduced setup times, fewer mistakes, and overall higher productivity are the results of machine operators and production workers being more acquainted with the process. Lower labor expenses per unit and perhaps shorter turnaround times may be achieved via this enhanced efficiency. Furthermore, higher quantities might justify the purchase of more advanced automation or specialized machinery, leading to even greater improvements in production efficiency. Nevertheless, it should be mentioned that these efficiency improvements could reach a ceiling at some time, and that other variables, including material prices, would still have a major impact on final pricing.

Conclusion

Customers and manufacturers alike must have a firm grasp of the building blocks that constitute CNC turning pricing if they are to arrive at solutions that are both practical and affordable. The ultimate cost of CNC-turned parts is highly dependent on material choice, the intricacy of the item, and the quantity of manufacturing. By carefully considering these factors and working closely with experienced CNC machining service providers, it's possible to optimize designs, streamline production processes, and achieve the best balance between cost and quality. To keep prices low in the CNC turning sector as technology evolves, it is essential to keep up with new materials, machining processes, and automation opportunities.

Affordable CNC Turning Solutions from Reliable Supplier | BOEN

For both prototypes and low-volume production, BOEN Prototype offers top-notch CNC turning solutions. Whether you're working with metals or plastics, our state-of-the-art CNC machining skills will provide you consistent, accurate results. We pride ourselves on our reasonable pricing, rapid turnaround times, and experienced assistance that is available every step of the way. We can handle even the most complicated pieces with precision and ease because to our modern machinery and skilled workforce. Choose BOEN for reliable, cost-effective CNC turning services tailored to your specific needs. Contact us at contact@boenrapid.com to discuss your project requirements.

References

1. Smith, J. (2022). Advanced CNC Turning Techniques for Cost Optimization. Journal of Manufacturing Technology, 15(3), 245-260.

2. Johnson, A., & Brown, M. (2021). Material Selection Strategies in CNC Machining: A Cost Analysis. International Journal of Production Economics, 232, 107931.

3. Lee, K., & Park, S. (2023). The Impact of Part Complexity on CNC Turning Costs: A Comprehensive Study. Journal of Materials Processing Technology, 310, 117624.

4. Wilson, R. (2022). Economies of Scale in CNC Manufacturing: A Case Study Approach. Production Planning & Control, 33(6-7), 571-585.

5. Chen, X., & Liu, Y. (2021). Design for Manufacturability: Optimizing CNC Turned Components. Journal of Cleaner Production, 295, 126431.

6. Thompson, E. (2023). The Future of CNC Turning: Cost Reduction Through Automation and AI. Robotics and Computer-Integrated Manufacturing, 80, 102439.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.