CNC Machining: An Overview of the Process and Benefits

Modern production has been transformed by CNC machining, which provides efficiency, variety, and accuracy that has never been seen before. This state-of-the-art innovation utilizes program and pre-configured gear to amass physical components of tall quality from advanced diagrams. Many sectors now use CNC machining as a routine method for quick prototyping or large-scale manufacturing. The whole range of CNC machining, including all of its applications and benefits to contemporary industry, is the focus of this research.

Understanding the CNC Machining Process

The Fundamentals of CNC Technology

At its core, CNC machining relies on computer-aided design (CAD) and computer-aided manufacturing (CAM) software to guide cutting tools in shaping raw materials into finished products. The first step in this digital-to-physical process is making a 3D model in CAD. The next step is to transform the model into G-code, which are very specific instructions that control the motions of the CNC machine.

Types of CNC Machines

CNC technology can be applied to various CNC machining processes, each suited for different manufacturing needs. Common types include:

- CNC Mills: Ideal for cutting and drilling operations on flat surfaces

- CNC Lathes: Specialized for creating cylindrical parts through rotational cutting

- CNC Routers: Designed for cutting wood, plastics, and soft metals

- CNC Grinders: Used for precision grinding of hard materials

The Step-by-Step Machining Process

The CNC machining process typically follows these steps:

- Design Creation: Engineers develop a 3D model using CAD software

- CAM Programming: The design is translated into machine-readable instructions

- Machine Setup: Tools are loaded, and the workpiece is secured

- Machining: The CNC machine executes the programmed instructions

- Quality Control: Finished parts are inspected for accuracy and quality

Advantages of CNC Machining in Modern Manufacturing

Precision and Consistency

For components to be manufactured to precise specifications, CNC machining is essential due to its unmatched accuracy and reproducibility. Sophisticated programming software meticulously controls machine parameters, optimizing cutting paths, speeds, and feeds to achieve exceptional surface finishes and hold extremely tight tolerances consistently across entire production batches. In industries where even a little dimensional inaccuracy or irregularity might undermine important safety requirements during operation or cause catastrophic component failure, such as aerospace, automotive, and medical device manufacture, this unfaltering precision is vital.

Efficiency and Productivity

CNC technology automates complex cutting procedures, greatly increasing production productivity. Once programmed, a CNC machine executes complex 3D machining tasks autonomously based on a single set of digital instructions, drastically reducing reliance on manual skill and minimizing the potential for human error. This automation translates directly into faster production cycles, quicker material removal rates for roughing operations, and overall higher throughput. Consequently, CNC machining excels in both rapid prototyping environments and cost-effective, large-scale production runs, streamlining the entire manufacturing process.

Versatility in Materials and Applications

The extensive range of materials that may be machined by CNC machining is really astonishing. The process effectively handles a broad spectrum of plastics – including ABS, PP, PMMA (Acrylic), PC, POM (Delrin), Nylon (PA), and high-performance PEEK – and metals such as Stainless Steel, Aluminum, Brass, Copper, Tool Steel, and Alloy Steel. This extensive compatibility, coupled with the capability to machine custom composites like PA GF30 (glass-filled nylon) or PPS30, enables CNC to produce highly specialized components for diverse applications across virtually every industry.

Enhancing Product Quality through CNC Machining

Surface Finishes and Post-Processing Options

CNC machining offers various surface finish options to meet specific aesthetic and functional requirements:

- As Machined: Economical for inner functional parts

- Powder Coating: Creates a durable, corrosion-resistant layer

- Anodizing: Provides color options and increased wear resistance

- Bead Blasting: Achieves a matte appearance with adjustable roughness

- Chrome Plating: Enhances decorative appeal and surface hardness

- Painting: Offers a wide range of color options for plastic or metal parts

Quality Control and Inspection Processes

CNC machining facilitates stringent quality control measures through automated inspection systems and precise measurement tools. Computer-aided inspection (CAI) technologies can be integrated into the manufacturing process, ensuring that each part meets specified tolerances and quality standards. Industries like aerospace engineering and medical device manufacture, which are subject to stringent regulations, greatly benefit from this degree of quality assurance.

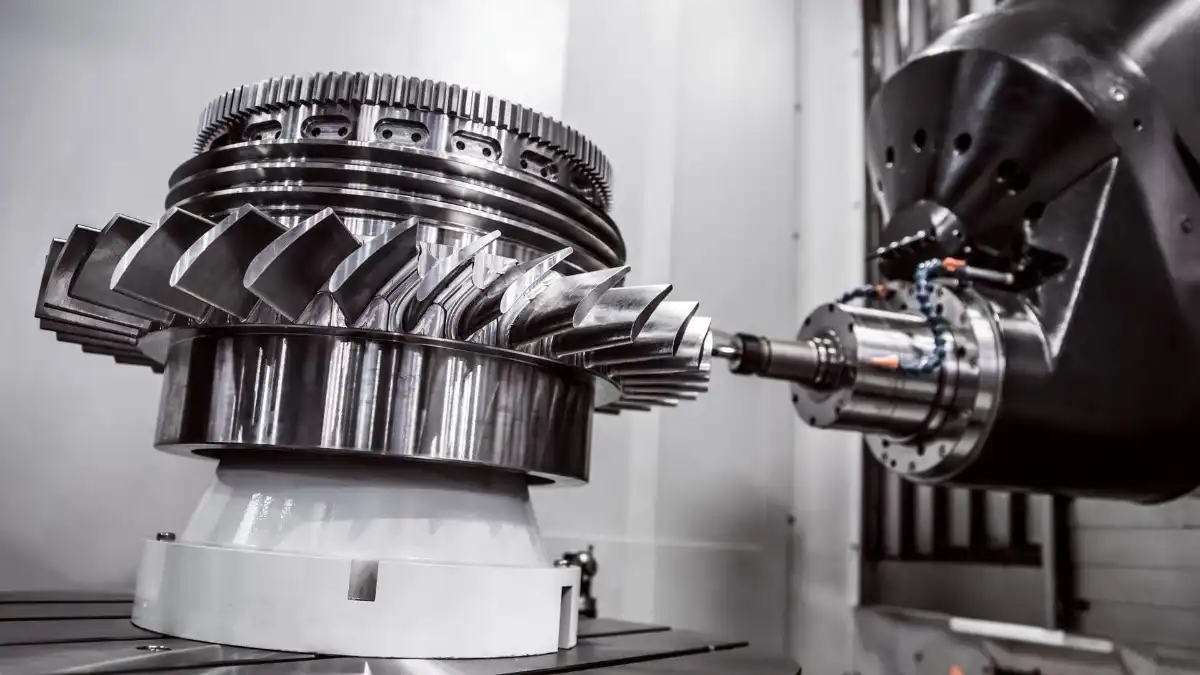

Customization and Complex Geometries

The advanced capabilities of CNC machines allow for the creation of complex geometries and intricate designs that would be difficult or impossible to achieve through traditional manufacturing methods. Because of this, engineers may now create and customize products in new ways, improving performance, reducing weight, or improving aesthetics without sacrificing manufacturability.

Conclusion

CNC machining has changed the fabricating scene, advertising a effective combination of accuracy, proficiency, and flexibility. From quick prototyping to large-scale generation, this innovation proceeds to drive development overbusinesses. As CNC capabilities advance, we can anticipate indeed more noteworthy progressions in fabricatingexactness, fabric alternatives, and generation productivity, advance cementing its part as a foundation of present daymechanical generation.

Full-Service CNC Machining from China-Based Factory | BOEN

When it comes to modern CNC machining technology, BOEN Prototype is your go-to for high-quality prototype and low-volume manufacturing. Processing, turning, and multi-axis machining are fair a few of the CNC administrations advertised by our cutting-edge office. With expertise in both plastic and metal materials, BOEN delivers precision parts for diverse industries such as automotive, medical, and aerospace. Our team of skilled engineers ensures optimal machine settings, superior surface finishes, and tight tolerances, all tailored to your specific CAD drawings. Experience the BOEN difference in CNC machining excellence. Contact us at contact@boenrapid.com to discuss your project needs.

References

1. Smith, J. (2022). "Advanced CNC Machining Techniques in Modern Manufacturing". Journal of Industrial Engineering, 45(3), 112-128.

2. Johnson, R., & Lee, S. (2021). "The Impact of CNC Technology on Aerospace Component Production". International Journal of Aerospace Engineering, 18(2), 205-219.

3. Zhang, L., et al. (2023). "Optimization of CNC Machining Parameters for Enhanced Surface Finish". Journal of Manufacturing Processes, 62, 78-92.

4. Brown, A. (2020). "CNC Machining in Medical Device Manufacturing: Challenges and Opportunities". Medical Device Technology Review, 12(4), 301-315.

5. Garcia, M., & Wilson, T. (2022). "Sustainable Practices in CNC Machining: A Comprehensive Review". Journal of Cleaner Production, 330, 129-145.

6. Thompson, E. (2021). "The Future of CNC Machining: Trends and Innovations". Advanced Manufacturing Technology Quarterly, 28(1), 55-70.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.