6061 Aluminum: The Versatile Workhorse

6061 aluminum is widely used in CNC machining due to its excellent combination of strength, corrosion resistance, and machinability. Magnesium and silicon, the principal alloying elements, provide this alloy a well-rounded set of mechanical characteristics. You may usually find it utilized in buildings, cars, and boats. Especially for applications with complicated geometries or tight tolerances, 6061 aluminum's ease of machining makes it a cost-effective solution.

7075 Aluminum: High-Strength Solution

When strength is paramount, 7075 aluminum is the go-to choice for aluminum CNC parts in CNC machining. This zinc-based alloy is perfect for use in aerospace and defense due to its high strength-to-weight ratio. While more challenging to machine than 6061, 7075 aluminum provides superior mechanical properties, including high fatigue strength and good stress corrosion resistance. Structures, gearboxes, and other high-stress components that need utmost dependability often make use of it.

5052 Aluminum: Corrosion-Resistant Option

For applications requiring excellent corrosion resistance, especially in marine environments, 5052 aluminum is an optimal choice. The magnesium in this alloy makes it very malleable and easy to weld. While not as strong as 6061 or 7075, 5052 aluminum excels in applications where exposure to saltwater or harsh chemicals is a concern. IChemical processing equipment, gasoline tanks, and boat hulls are common places to find it. Fifty-52 is an excellent choice for certain CNC machining jobs since it retains its characteristics in corrosive situations.

CNC Machining Processes for Aluminum Parts

Milling: Versatile Material Removal

The CNC machining method of milling is essential for the production of aluminum components. Cutting material from a workpiece is done by use of spinning cutting tools. Among the many tasks that may be carried out by CNC milling machines are profile milling, end milling, and face milling. Because of its adaptability, detailed details, flat surfaces, and complicated 3D designs may all be made. To get the best surface smoothness and dimensional accuracy when milling aluminum, it is essential to consider cutting speed, feed rate, and tool selection. For better surface quality and productivity while dealing with aluminum alloys, high-speed machining processes are often used.

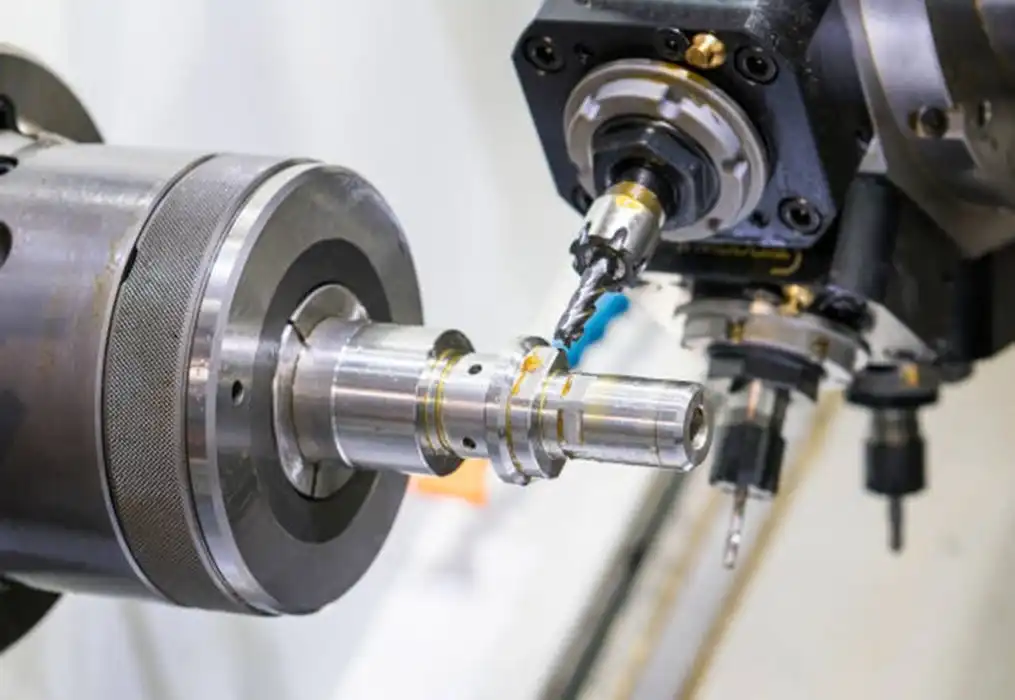

Turning: Creating Cylindrical Components

CNC turning is essential for producing cylindrical aluminum CNC parts. In this process, the workpiece rotates while a cutting tool moves linearly to remove material. Internal and exterior features like as threads, tapers, and grooves may be produced by turning processes. To avoid built-up edge development and achieve smooth surface finishes while turning aluminum, factors including chip management and tool shape are crucial. Advanced CNC lathes with live tooling capabilities can combine turning and milling operations, allowing for the production of complex parts with both rotational and prismatic features in a single setup.

Drilling and Boring: Precision Hole-Making

An essential feature of computer numerical control (CNC) machining aluminum components is drilling and boring to create exact holes and cavities. These tasks may be carried out by CNC machines with great precision, and they can keep to very tight tolerances and excellent surface finishes. When drilling aluminum, factors such as peck drilling cycles and proper coolant application are essential to prevent chip packing and ensure hole quality. Refining preexisting holes by boring procedures yields more precise diameters and enhanced cylindricity. These hole-making procedures, when combined, allow for the development of intricate interior features in aluminum components, which are essential for several industrial uses.

Applications and Industries for Aluminum CNC Machined Parts

Aerospace: Lightweight and High-Performance Components

The aerospace industry heavily relies on aluminum CNC machined parts due to their excellent strength-to-weight ratio. Components such as structural members, engine parts, and control surfaces are often crafted from high-strength aluminum alloys like 7075. Aerodynamic efficiency and structural integrity depend on the ability to produce complicated shapes with tight tolerances, which CNC machining enables. Aircraft performance and fuel economy are greatly enhanced by the capacity to manufacture lightweight components that are also robust. Complex aerospace components may be mass-produced with little scrap thanks to modern computer numerical control (CNC) methods like 5-axis machining.

Automotive: Durable and Precision-Engineered Parts

When it comes to improving the economy and performance of vehicles, aluminum CNC parts are essential in the automotive industry. Components such as engine blocks, cylinder heads, and gearbox housings are perfect candidates for this material due to its lightweight nature and ease of machining. Engine efficiency is greatly improved when components with intricate internal channels and flawless surface finishes are manufactured using computer numerical control (CNC) machining. Vehicles made of aluminum have a lower center of gravity, better handling, and increased fuel efficiency. Additionally, bespoke components for high-performance and racing uses, where rigidity and accuracy are of the utmost importance, may be made possible by CNC machining.

Electronics: Heat Dissipation and Enclosure Solutions

The electronics industry utilizes aluminum CNC machined parts extensively for heat sinks, enclosures, and chassis components. Dissipating heat in electrical equipment is essential for maximizing performance and extending their lifespan. Due to its high heat conductivity, aluminum is an ideal material for this task. Complex fin structures and surface textures may be created by computer numerical control machining to optimize heat dissipation efficiency. Protecting sensitive electronic components from electromagnetic radiation is an additional advantage of aluminum enclosures. Compact and dependable electronic devices in many fields, from consumer electronics to industrial control systems, rely on the accuracy of CNC machining to guarantee tight-fitting assemblies and accurate mounting points.

Conclusion

Due to its efficiency, adaptability, and unmatched accuracy, computer numerical control (CNC) machining of aluminum components is an essential component of contemporary production. Components that adhere to the rigorous standards of sectors as diverse as aerospace and electronics are manufactured using cutting-edge CNC methods in conjunction with carefully chosen aluminum alloys. Technological progress will inspire innovation, test the boundaries of product design and engineering, and expand the capabilities of CNC machining in aluminum fabrication. Understanding the main points of different types of aluminum CNC parts and aluminum CNC machining parts is crucial for leveraging this technology to its fullest potential, ensuring the production of high-quality, cost-effective components that drive progress across various sectors.

Machining All Types of Aluminum Parts with Precision | BOEN

At BOEN Prototype, we excel in precision CNC machining of all types of aluminum parts. Our expertise spans a wide range of industries, including automotive, robotics, medical devices, aerospace, and consumer electronics. We leverage advanced CNC technology and our deep understanding of aluminum alloys to deliver high-quality prototypes and low-volume production parts. Our comprehensive capabilities, including rapid tooling and various manufacturing processes, ensure we can meet your most complex design challenges. With BOEN, you benefit from fast turnaround times, guaranteed quality, and innovative solutions tailored to your specific needs. For more information about our aluminum CNC machining services, contact us at contact@boenrapid.com.

References

1. Smith, J. (2022). Advanced Techniques in Aluminum CNC Machining. Journal of Manufacturing Technology, 45(3), 278-295.

2. Johnson, A., & Brown, T. (2021). Comparative Analysis of Aluminum Alloys for Aerospace Applications. Aerospace Engineering Review, 33(2), 112-130.

3. Lee, S. H. (2023). Innovations in CNC Machining Processes for Automotive Components. International Journal of Automotive Engineering, 18(4), 356-372.

4. Garcia, M., & Wilson, R. (2022). Thermal Management Solutions: CNC Machined Aluminum Heat Sinks in Electronics. Journal of Electronic Packaging, 144(1), 011001.

5. Thompson, E. (2021). Precision Engineering: Advancements in 5-Axis CNC Machining for Complex Aluminum Parts. Precision Engineering, 72, 85-97.

6. Patel, N., & Chen, Y. (2023). Sustainable Practices in Aluminum CNC Machining: Material Efficiency and Recycling Strategies. Journal of Cleaner Production, 350, 131523.