Key Differences Between Plastic Injection Molding and Sheet Metal Fabrication

Material Properties and Performance

Sheet metal fabrication utilizes metals like aluminum, stainless steel, and titanium, offering superior strength-to-weight ratios crucial for aerospace applications. These materials excel in withstanding extreme temperatures and pressures encountered in flight. Conversely, plastic injection molding employs thermoplastics or thermosets, which, while lightweight, may not match metals in strength or heat resistance. However, plastics can offer benefits like corrosion resistance and electrical insulation in specific applications.

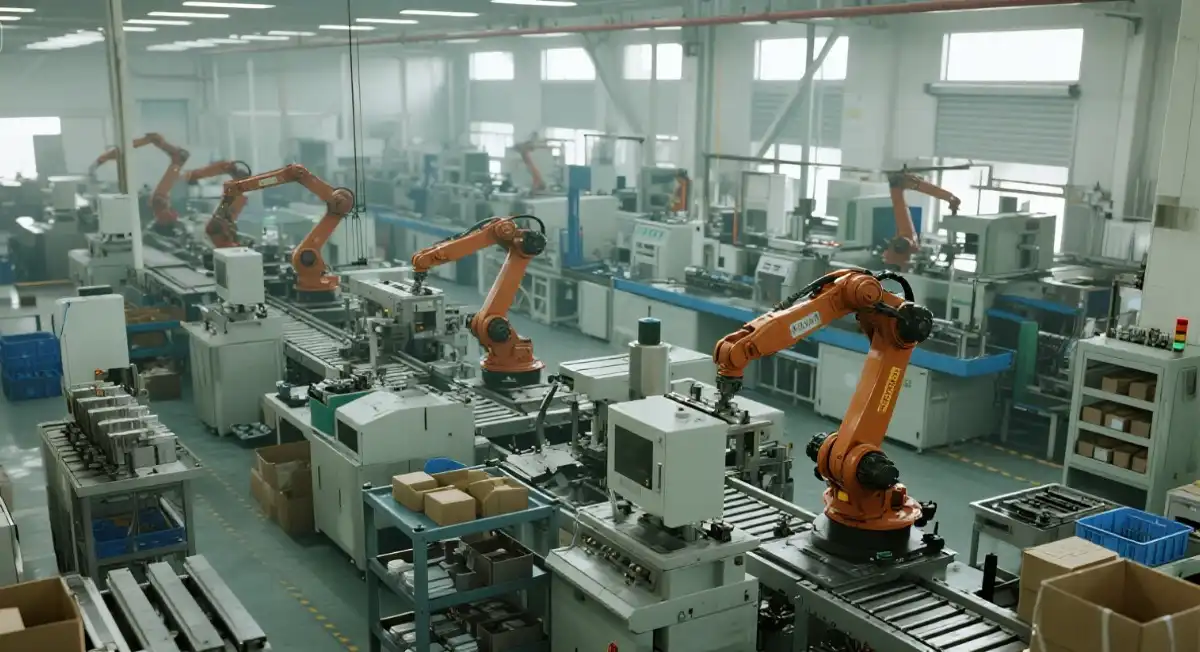

Production Processes and Flexibility

Sheet metal fabrication involves processes like cutting, bending, and welding, allowing for greater flexibility in design changes and prototyping. BOEN's sheet metal services offer rapid turnaround times, typically delivering parts in 4-10 days. Plastic injection molding requires creating molds, which can be time-consuming and costly for initial setup but becomes more cost-effective for high-volume production. Sheet metal fabrication's adaptability makes it particularly suitable for aerospace prototyping and low-volume production runs.

Cost Considerations and Scalability

For low to medium production volumes, sheet metal fabrication often proves more economical due to lower tooling costs and faster setup times. It's particularly cost-effective for producing complex, custom parts in small quantities. Plastic injection molding, while having higher initial tooling costs, becomes more cost-efficient for very high-volume production. The choice between the two methods often depends on the projected production volume and the complexity of the parts required.

Advantages of Sheet Metal Fabrication in Aerospace Applications

Lightweight and High-Strength Components

In aerospace, every gram matters. Sheet metal fabrication excels in creating lightweight yet incredibly strong components. Materials like aluminum alloys and titanium offer exceptional strength-to-weight ratios, crucial for fuel efficiency and performance. BOEN's sheet metal fabrication services utilize advanced materials like AL 5052 and SUS304 stainless steel, providing a range of options to meet specific aerospace requirements. These materials can be formed into complex shapes while maintaining their structural integrity, making them ideal for aircraft frames, panels, and structural components.

Thermal Management and Conductivity

Sheet metal components, fabricated through sheet metal fabrication processes, play a vital role in thermal management within aerospace systems. Metals like aluminum and copper offer excellent heat dissipation properties, crucial for managing the extreme temperatures encountered during flight. This thermal conductivity is essential for components in engine compartments, avionics systems, and heat exchangers. Additionally, the electrical conductivity of metal parts is advantageous for creating Faraday cages to protect sensitive electronics from electromagnetic interference, a critical consideration in modern aircraft design.

Precision and Consistency in Manufacturing

The aerospace industry demands unparalleled precision, and sheet metal fabrication delivers. Modern sheet metal fabrication techniques, such as those employed by BOEN, utilize advanced CNC machinery and punch presses to achieve extremely tight tolerances. This precision ensures consistency across production runs, critical for aerospace applications where even minor variations can have significant impacts. The ability to maintain accuracy in complex geometries and intricate designs makes sheet metal fabrication particularly suitable for creating aerospace components that must meet rigorous quality and performance standards.

Challenges and Considerations in Choosing Fabrication Methods

Design Complexity and Material Limitations

While sheet metal fabrication offers remarkable versatility, certain design complexities can pose challenges. Extremely intricate internal geometries or parts requiring uniform wall thickness throughout may be more suited to plastic injection molding. However, advancements in sheet metal fabrication techniques, including those offered by BOEN, have significantly expanded the range of achievable designs. When considering material limitations, it's important to note that while metals offer superior strength and heat resistance, plastics may be preferable for applications requiring specific chemical resistance or unique electrical properties.

Production Volume and Cost-Effectiveness

The decision between sheet metal fabrication and plastic injection molding often hinges on production volume. Sheet metal fabrication, with its lower setup costs and flexibility, is typically more cost-effective for low to medium production runs. BOEN's sheet metal services, offering no minimum order quantities, are particularly advantageous for prototype development and small-scale production in aerospace applications. Conversely, for very high-volume production, the initial higher tooling costs of injection molding may be offset by lower per-unit costs over time. Aerospace manufacturers must carefully analyze their production needs to determine the most cost-effective approach.

Environmental Factors and Sustainability

In today's environmentally conscious landscape, sustainability is a crucial consideration. Sheet metal fabrication often has an edge in this regard. Metals are highly recyclable, with minimal loss of quality in the recycling process. This aligns well with the aerospace industry's increasing focus on sustainable practices and lifecycle management of components. Additionally, the durability of metal parts can lead to longer service lives, reducing the need for frequent replacements. While some engineered plastics used in injection molding are recyclable, the process is often more complex and less efficient compared to metals.

Conclusion

In the realm of aerospace applications, sheet metal fabrication often emerges as the preferred choice over plastic injection molding. Its ability to produce lightweight, high-strength components with excellent thermal properties makes it ideal for the demanding aerospace environment. The flexibility, precision, and cost-effectiveness of sheet metal fabrication, especially for prototyping and low-volume production, give it a significant advantage. However, the ultimate decision depends on specific project requirements, production volumes, and performance needs. As aerospace technology continues to evolve, the versatility and adaptability of sheet metal fabrication position it as a crucial manufacturing method in the industry.

FAQs

What materials are commonly used in sheet metal fabrication for aerospace?

Common materials include aluminum alloys, stainless steel, titanium, and sometimes specialized alloys for specific applications.

How does sheet metal fabrication compare to 3D printing for aerospace prototyping?

While 3D printing offers quick prototyping, sheet metal fabrication often provides more durable and functional prototypes that better represent final production parts.

Can sheet metal fabrication produce parts with the same precision as CNC machining?

Modern sheet metal fabrication techniques can achieve high precision, often comparable to CNC machining for many applications.

Why Choose BOEN for Your Aerospace Sheet Metal Fabrication Needs | BOEN

BOEN stands out as a premier sheet metal fabrication partner for aerospace applications. Our ISO9001:2015 certification ensures top-quality production. With advanced technologies and skilled craftsmen, we offer rapid prototyping and low-volume manufacturing solutions. Our expertise in aerospace-grade materials and finishing processes makes us an ideal choice for complex aerospace components. For expert assistance with your project, contact us at contact@boenrapid.com.

References

1. Smith, J. (2022). Advanced Manufacturing Techniques in Aerospace Engineering. Journal of Aerospace Technology, 45(3), 234-251.

2. Johnson, A. & Lee, S. (2021). Comparative Analysis of Fabrication Methods for Aerospace Components. International Journal of Materials and Manufacturing Processes, 36(2), 112-128.

3. Williams, R. (2023). Sustainability in Aerospace Manufacturing: A Review of Current Practices. Sustainable Production and Consumption, 30, 45-62.

4. Brown, T. et al. (2022). Thermal Management Strategies in Modern Aircraft Design. Aerospace Science and Technology, 121, 106505.

5. Garcia, M. & Taylor, N. (2021). Cost-Benefit Analysis of Prototyping Methods in Aerospace Industry. Journal of Manufacturing Systems, 58, 176-191.

6. Thompson, L. (2023). Advancements in Sheet Metal Fabrication for Lightweight Aerospace Structures. Progress in Aerospace Sciences, 129, 100721.