Differences Between 3D Printing and RIM You Should Know

3D printing and Reaction Injection Molding (RIM) are two distinct manufacturing processes, each with unique advantages. 3D printing, an additive method, builds objects layer by layer using materials like plastics or resins. RIM, on the other hand, involves injecting liquid polymers into a mold where they react and solidify. While 3D printing excels in prototyping and small-batch production, RIM is ideal for larger volumes of complex parts. Understanding these differences is crucial for choosing the right method for your project, considering factors like production volume, material properties, and design complexity.

Understanding 3D Printing Technology

Additive Manufacturing Process

3D printing, also known as additive manufacturing, is a revolutionary technology that creates three-dimensional objects by depositing materials layer by layer. This process begins with a digital 3D model, typically created using Computer-Aided Design (CAD) software. The model is then sliced into thin layers, which the printer uses as a blueprint to build the object.

At BOEN, we specialize in two primary 3D printing technologies: Stereolithography (SLA) and Selective Laser Sintering (SLS). SLA uses a laser to cure and solidify liquid resin, while SLS employs a laser to sinter powdered materials like nylon or polyamide. Both technologies offer high precision and the ability to create complex geometries that would be challenging or impossible with traditional manufacturing methods.

Materials and Applications

3D printing accommodates a wide range of materials, including various plastics, resins, and even some metals. At BOEN, we offer materials such as PA (polyamide), ABS, and opaque PMMA (acrylic). Each material has unique properties suited for different applications, from functional prototypes to end-use parts.

The versatility of 3D printing makes it ideal for rapid prototyping, custom product development, and small-scale production. Industries like automotive, medical devices, aerospace, and consumer electronics benefit from the quick turnaround times and design flexibility offered by 3D printing.

Advantages and Limitations

3D printing offers several advantages, including reduced lead times, lower costs for small batches, and the ability to create complex geometries without additional tooling. It's particularly beneficial for rapid prototyping and iterative design processes. However, it does have limitations, such as potentially slower production speeds for large volumes and material constraints compared to traditional manufacturing methods.

Exploring Reaction Injection Molding (RIM)

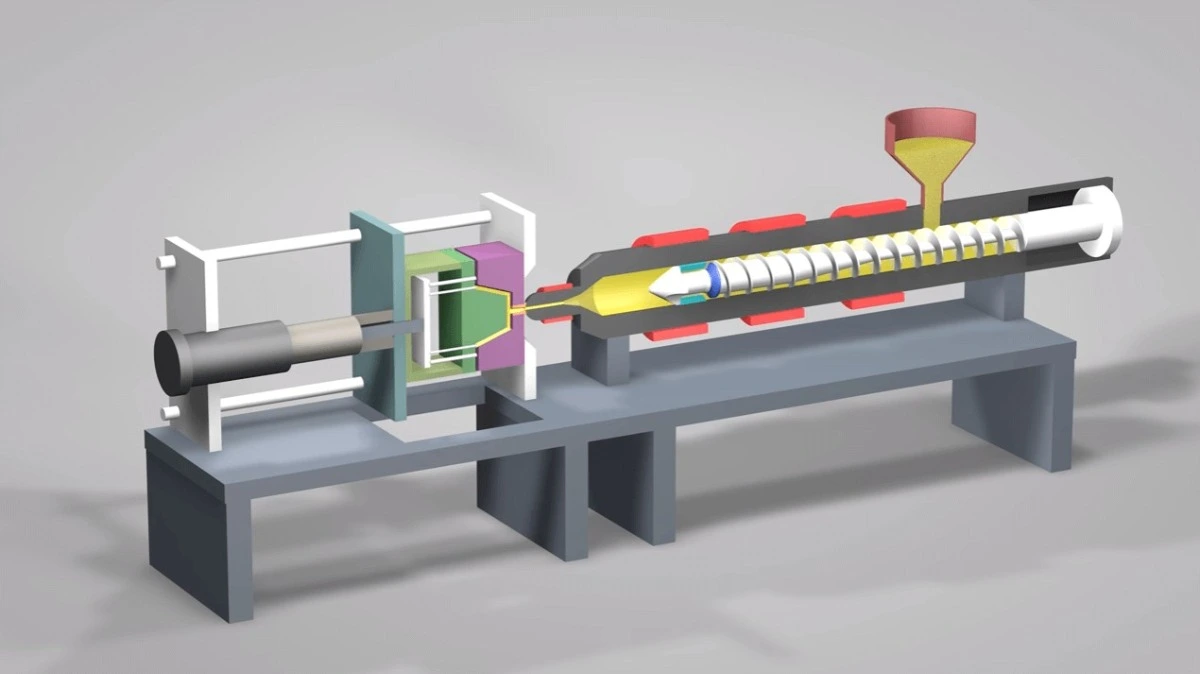

RIM Process Overview

Reaction Injection Molding (RIM) is a manufacturing process that involves mixing two or more liquid components and injecting them into a mold. These components react chemically within the mold, rapidly forming a solid part. The RIM process is known for its ability to produce large, complex parts with excellent surface finish and dimensional stability.

Unlike traditional injection molding, RIM uses lower pressures and temperatures, allowing for the use of less expensive molds and making it suitable for larger parts. The chemical reaction that occurs during the process contributes to the final properties of the part, offering unique material characteristics.

Materials and Applications in RIM

RIM typically uses thermoset polymers, with polyurethane being the most common. These materials offer excellent strength-to-weight ratios, impact resistance, and insulation properties. Other materials used in RIM include polyureas, polyisocyanurates, and nylons.

The RIM process is widely used in automotive industries for producing large body panels, bumpers, and interior components. It's also utilized in the production of medical equipment, furniture, and industrial machinery parts. The ability to create large, structurally sound parts with complex geometries makes RIM a versatile manufacturing method, while 3D printing offers an alternative for rapid prototyping and complex geometries.

Advantages and Considerations of RIM

RIM offers several advantages, including the ability to produce large parts with complex shapes, excellent surface finish, and good dimensional stability. It's also cost-effective for medium to large production runs and allows for the integration of inserts and reinforcements during the molding process. However, RIM requires significant upfront investment in molds and equipment, making it less suitable for small production runs or frequent design changes.

Comparing 3D Printing and RIM: Making the Right Choice

Production Volume Considerations

When deciding between 3D printing and RIM, production volume is a crucial factor. 3D printing excels in low-volume production and prototyping, offering quick turnaround times and cost-effectiveness for small batches. It's ideal for producing 1-1000 parts without the need for tooling.

RIM, on the other hand, becomes more economical at higher volumes, typically above 1000 units. The initial mold costs are offset by faster production speeds and lower per-unit costs as volume increases. For medium to large production runs, RIM often proves more cost-effective than 3D printing.

Design Complexity and Material Properties

Both 3D printing and RIM can handle complex geometries, but they differ in their approach. 3D printing allows for intricate internal structures and can produce parts that would be impossible to mold. It's particularly advantageous for lightweight, optimized designs.

RIM excels in producing large, complex parts with consistent material properties throughout. It offers superior surface finish and can integrate different materials or inserts during the molding process. The chemical reaction in RIM also allows for unique material properties that may be difficult to achieve with 3D printing.

Time and Cost Analysis

3D printing offers rapid prototyping capabilities, allowing for quick design iterations and faster time-to-market for new products. It's cost-effective for small batches and doesn't require tooling, reducing upfront costs.

RIM has higher initial costs due to mold production but offers faster production speeds for larger volumes. Over time, RIM can be more cost-effective for high-volume production, especially for large parts. The choice between 3D printing and RIM often comes down to balancing time-to-market, production volume, and long-term cost considerations.

Conclusion

Choosing between 3D printing and RIM depends on your specific project requirements. 3D printing offers unparalleled flexibility for prototyping and small-batch production, while RIM excels in producing larger volumes of complex, durable parts. At BOEN, we specialize in 3D printing services, offering fast turnaround times and high-quality results for your prototyping and low-volume production needs. Our expertise in SLA and SLS technologies ensures precise, custom parts across various industries. Consider your production volume, design complexity, and material requirements to make the best choice for your manufacturing needs.

FAQs

What materials can be used in 3D printing?

3D printing can use various materials including plastics like PA, ABS, and PMMA, as well as resins and some metals.

Is 3D printing suitable for mass production?

While 3D printing is typically best for prototypes and small batches, advancements are making it increasingly viable for larger production runs.

What are the main advantages of RIM over 3D printing?

RIM offers faster production for large volumes, better surface finish, and the ability to produce larger parts more economically.

Why Choose BOEN for Your 3D Printing Needs | BOEN

BOEN stands out as a leading provider of 3D printing services, offering both SLA and SLS technologies. Our expertise in rapid prototyping and low-volume production ensures high-quality, precise parts with quick turnaround times. We cater to various industries, providing custom solutions for complex designs. Choose BOEN for your 3D printing needs and experience our commitment to excellence. For inquiries, contact us at contact@boenrapid.com.

References

1. Johnson, A. (2022). Advancements in 3D Printing Technologies. Journal of Manufacturing Innovation, 15(3), 245-260.

2. Smith, B. & Lee, C. (2021). Reaction Injection Molding: Principles and Applications. Industrial Manufacturing Quarterly, 28(2), 112-128.

3. Anderson, R. (2023). Comparative Analysis of Additive and Reactive Manufacturing Processes. Advanced Materials Processing, 42(1), 78-95.

4. Wilson, D. et al. (2022). Material Selection for 3D Printing and RIM: A Comprehensive Guide. Materials Science and Engineering International, 37(4), 301-318.

5. Chen, L. & Davis, M. (2023). Cost-Benefit Analysis of 3D Printing vs. Traditional Manufacturing Methods. Journal of Production Economics, 19(2), 156-172.

6. Thompson, K. (2021). Design Optimization for Additive Manufacturing: Challenges and Opportunities. Engineering Design Technology Review, 33(3), 210-225.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.