Comparison Between Rapid Prototyping and Low Volume Production in 2025

As we move through 2025, the landscape of manufacturing is evolving significantly. Rapid prototyping and low volume production are playing crucial roles in this transformation. While rapid prototyping focuses on quickly creating initial models, low volume production aims at manufacturing small batches efficiently. Today, advancements in materials, technologies, and processes are blurring the lines between these two approaches. Companies are benefiting from faster time-to-market, reduced costs, and increased flexibility. The key difference lies in the scale and finish quality, with low volume production offering more refined, market-ready products in limited quantities.

The Evolution of Rapid Prototyping Technologies

Advancements in 3D Printing

In 2025, 3D printing technology is achieving significant breakthroughs, particularly through the adoption of multi-material printing systems. These innovative printers are enabling the fabrication of complex components with diverse mechanical and thermal properties in a single build process. Such capabilities are greatly enhancing prototype accuracy, making it possible to create models that closely resemble final products in both form and function. Additionally, nano-scale 3D printing is becoming more widely available, allowing for high-precision manufacturing of micro-scale structures essential to advanced applications in biomedicine, electronics, and materials science.

Integration of AI and Machine Learning

The incorporation of artificial intelligence and machine learning is set to transform rapid prototyping by introducing data-driven optimization across the design and testing stages. AI algorithms will automate and enhance design iteration, simulate material performance under varying conditions, and identify potential flaws before physical production begins. Machine learning models will continuously improve prototyping workflows based on historical data, leading to reduced development time and lower costs. As a result, teams can iterate faster and with greater confidence, transitioning more efficiently from concept to low-volume production final product.

Sustainable Materials in Prototyping

Growing environmental awareness is accelerating the shift toward sustainable materials in prototyping. Bio-based polymers, recycled composites, and biodegradable resins are gaining prominence as viable alternatives to conventional petroleum-based materials. These eco-friendly options help minimize waste and carbon emissions throughout the product development cycle. Moreover, adopting sustainable materials supports corporate environmental goals and meets increasing consumer and regulatory demands for greener manufacturing practices.

Transformations in Low Volume Production

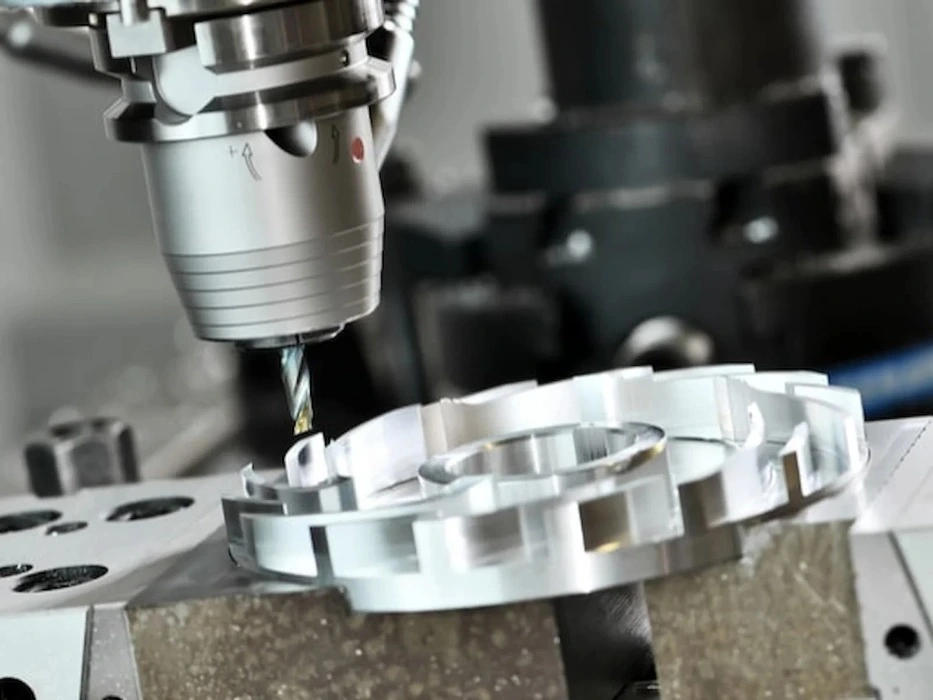

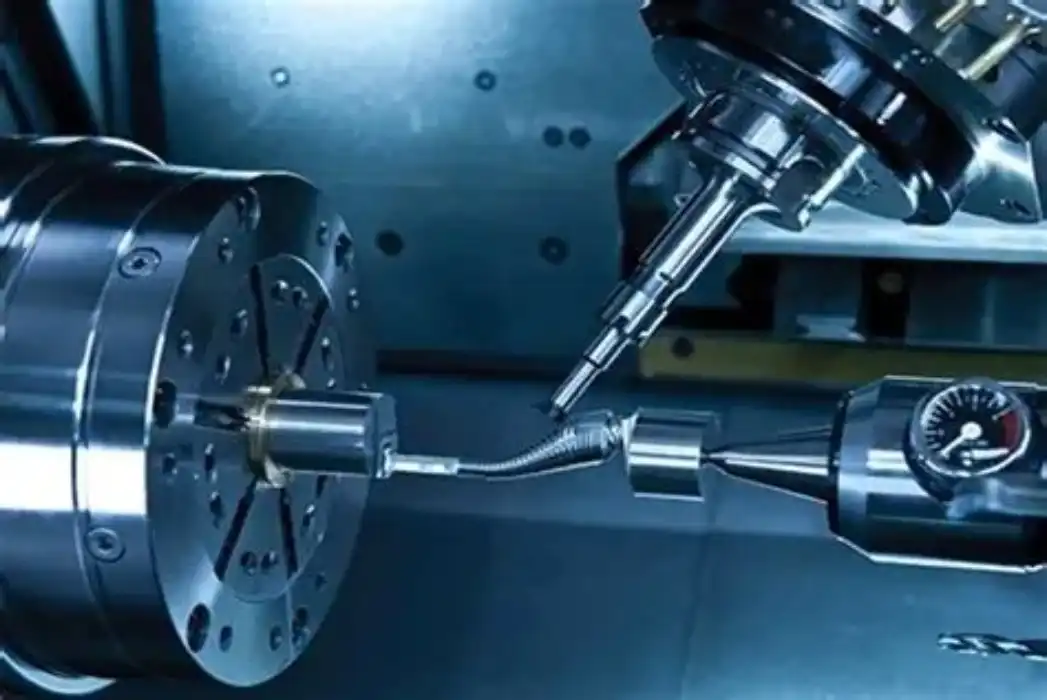

Flexible Manufacturing Systems

In 2025, low volume production will benefit from highly flexible manufacturing systems. These agile setups will allow quick changeovers between different products, enabling manufacturers to produce diverse items in small batches without significant downtime. Advanced robotics and modular production lines will facilitate this flexibility, making low volume production more cost-effective and responsive to market demands.

Digital Twin Technology in Production

Digital twin technology will play a pivotal role in optimizing low volume production. Virtual replicas of production processes will enable real-time monitoring, predictive maintenance, and process optimization. This technology will help manufacturers identify bottlenecks, simulate different production scenarios, and fine-tune operations for maximum efficiency, even in small-scale production runs.

Customization and Mass Personalization

Low volume production in 2025 will excel in delivering customized and personalized products. Advanced manufacturing techniques, coupled with sophisticated software, will allow for efficient production of unique items tailored to individual customer preferences. This capability will open new market opportunities and enable businesses to offer personalized products at scale, blurring the line between mass production and bespoke manufacturing.

Comparative Analysis of Rapid Prototyping and Low Volume Production

Cost Considerations

In 2025, the cost dynamics between rapid prototyping and low volume production will shift. Rapid prototyping will become more cost-effective for creating complex, one-off designs due to advancements in 3D printing and material sciences. Conversely, low volume production will benefit from increased automation and flexible manufacturing systems, reducing the per-unit cost for small batches. The choice between the two will depend on factors like product complexity, required finish quality, and production volume.

Time-to-Market Efficiency

Both rapid prototyping and low volume production will see significant improvements in time-to-market efficiency. Rapid prototyping will excel in quickly producing concept models and functional prototypes, allowing for faster design iterations. Low volume production, enhanced by digital technologies and agile manufacturing processes, will reduce lead times for small-scale production runs. This convergence will enable companies to move seamlessly from prototyping to market-ready products, accelerating the overall product development lifecycle.

Quality and Finish Comparisons

In 2025, the quality gap between rapid prototypes and low volume production parts will narrow. Advanced rapid prototyping technologies will produce parts with improved surface finishes and mechanical properties. However, low volume production will still hold an edge in producing parts with superior consistency and durability, especially for end-use applications. The choice between the two will depend on the specific requirements of the project, with rapid prototyping excelling in early-stage development and low volume production in creating market-ready products.

Conclusion

In 2025, the lines between rapid prototyping and low volume production are becoming increasingly blurred. Both methodologies are evolving to offer faster, more cost-effective, and flexible solutions for product development and manufacturing. The choice between rapid prototyping and low volume production will depend on specific project needs, balancing factors like speed, cost, quality, and production volume. Companies that can effectively leverage both approaches will gain a significant competitive advantage in bringing innovative products to market quickly and efficiently.

FAQs

What is the main difference between rapid prototyping and low volume production in 2025?

The main difference lies in scale and finish quality. Rapid prototyping focuses on quick iteration of designs, while low volume production aims at producing small batches of market-ready products.

How will AI impact rapid prototyping by 2025?

AI will optimize design iterations, predict material behavior, and streamline the prototyping workflow, reducing the number of physical prototypes needed.

What role will digital twin technology play in low volume production?

Digital twins will enable real-time monitoring, predictive maintenance, and process optimization, enhancing efficiency in small-scale production runs.

Innovative Solutions for Your Manufacturing Needs | BOEN

At BOEN, we're at the forefront of rapid prototyping and low volume production technologies. Our state-of-the-art facilities and expert team ensure high-quality results for your manufacturing needs. Whether you require quick prototypes or small production runs, BOEN delivers precision and efficiency. Experience our innovative solutions tailored to your specific requirements. Contact us at contact@boenrapid.com to explore how we can bring your ideas to life with unparalleled expertise and cutting-edge technology.

References

1. Smith, J. (2024). "The Future of Rapid Prototyping: Trends and Predictions for 2025." Journal of Advanced Manufacturing Technologies.

2. Johnson, L. et al. (2023). "Comparative Analysis of Rapid Prototyping and Low Volume Production Techniques." International Journal of Industrial Engineering.

3. Brown, A. (2024). "Sustainable Materials in Modern Manufacturing: A 2025 Outlook." Green Manufacturing Quarterly.

4. Lee, S. (2023). "Digital Twin Technology in Small-Scale Production: Opportunities and Challenges." Smart Factory Journal.

5. Wilson, M. (2024). "AI-Driven Design Optimization in Product Development." Artificial Intelligence in Engineering Design.

6. Garcia, R. (2023). "The Role of Flexible Manufacturing Systems in Low Volume Production." Journal of Manufacturing Systems and Automation.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.