Aerospace and Defense: Precision at New Heights

Cutting-Edge Aircraft Components

In the aerospace industry, laser cutting technology is essential for manufacturing lightweight yet extremely durable components. It allows aircraft manufacturers to produce highly intricate parts such as turbine blades, wing brackets, and fuselage panels with exceptionally tight tolerances. This level of precision ensures optimal aerodynamic performance, structural integrity, and safety compliance. Unlike conventional machining, laser cutting efficiently handles complex geometries and advanced materials like titanium and carbon-fiber composites, reducing waste and production time while maintaining consistent quality across large-scale operations.

Defense Equipment Fabrication

The defense sector extensively relies on laser cutting for the fabrication of critical equipment including armored vehicle plating, advanced weapon systems, and secure communication devices. Its precision is vital for creating ballistic-resistant surfaces and intricate components that meet strict military specifications. Laser cutting supports the use of high-strength alloys, ceramics, and composite materials, enabling the production of lightweight yet protective solutions. This technology enhances the durability, functionality, and reliability of next-generation defense systems, contributing directly to national security and tactical advantage.

Satellite and Space Exploration Hardware

Laser cutting plays a pivotal role in the production of hardware for satellite and space exploration missions, where components must endure extreme temperatures, radiation, and mechanical stress. It is used to manufacture precision parts such as satellite panels, thermal protection layers, sensor mounts, and engine components. The non-contact process minimizes heat-induced distortion, preserving the material properties of specialized alloys and ceramics. This accuracy is essential to ensuring the performance and longevity of equipment in the demanding environment of space.

Automotive: Driving Innovation in Manufacturing

Body Panel Production

The automotive industry extensively utilizes laser cutting technology for efficient and precise body panel manufacturing. This advanced method supports rapid prototyping, enabling designers to quickly iterate and validate concepts before seamlessly transitioning to full-scale production. Laser systems deliver exceptionally accurate cuts and complex perforations in a variety of materials, including high-strength steel and aluminum alloys. This contributes to the production of lighter vehicle structures, which directly enhances fuel efficiency and overall performance. The flexibility and speed of laser cutting make it indispensable in modern automotive manufacturing.

Interior Component Fabrication

Laser cutting is widely employed in fabricating detailed interior components such as dashboard panels, seat frames, and decorative trim pieces. It produces clean, burr-free edges that improve both aesthetic quality and functional safety. The technology accommodates a broad spectrum of materials—from textiles and composites to plastics and thin metals—enabling automakers to achieve complex designs and high levels of customization. This versatility simplifies supply chains and accelerates production, while maintaining consistency and reducing material waste.

Electric Vehicle Battery Production

With the growing shift toward electric vehicles, laser cutting has become essential in the production of EV batteries. It is used to cut and weld battery cells with extreme precision, create finely detailed electrode patterns, and fabricate reliable battery housings. Such accuracy is critical to ensuring battery safety, performance, and longevity. Laser cutting supports the manufacturing of lightweight and thermally efficient components, directly contributing to the energy density and durability of modern electric vehicle power systems.

Medical and Life Sciences: Advancing Healthcare through Precision

Medical Device Manufacturing

The medical industry relies on laser cutting for producing high-precision devices and instruments. From surgical tools to implantable devices, laser cutting ensures the utmost accuracy and cleanliness required in medical applications. Its ability to work with biocompatible materials like titanium and nitinol makes it indispensable in creating cutting-edge medical solutions.

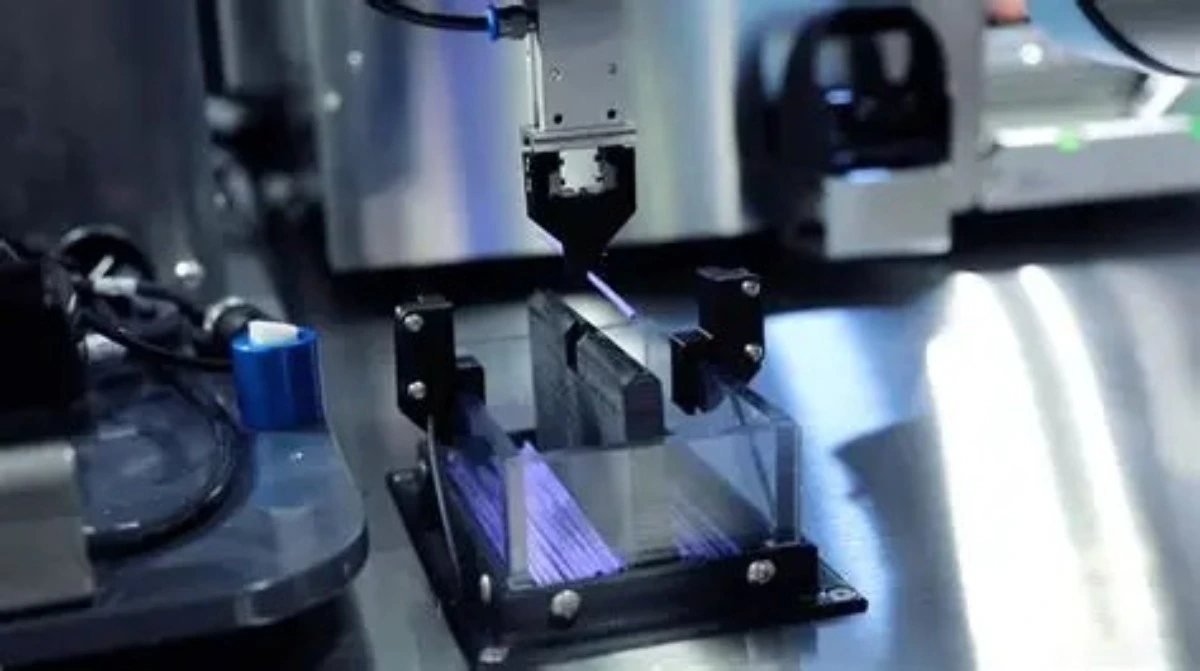

Microfluidic Device Fabrication

Laser cutting technology is instrumental in the production of microfluidic devices used in diagnostics and drug discovery. These devices require intricate channel networks and precise fluid control, which laser cutting can achieve with remarkable accuracy. The technology's ability to work with various polymers and glass materials makes it ideal for creating lab-on-a-chip devices and other miniaturized analytical tools.

Prosthetics and Orthotics

In the field of prosthetics and orthotics, laser cutting enables the creation of custom-fit devices tailored to individual patients. The technology allows for rapid prototyping and iteration of designs, improving comfort and functionality. Laser cutting's precision ensures that prosthetic components fit perfectly, enhancing the quality of life for users.

Conclusion

Laser cutting technology has become a cornerstone of modern manufacturing across various industries. Its unparalleled precision, versatility, and efficiency have transformed production processes in aerospace, automotive, and medical sectors. As industries continue to push the boundaries of innovation, laser cutting will undoubtedly play an even more significant role in shaping the future of manufacturing. The technology's ability to work with diverse materials and create complex designs positions it as a key enabler of progress in these critical industries.

FAQ

What materials can be laser cut?

Laser cutting can work with a wide range of materials, including metals, plastics, wood, textiles, and composites.

Is laser cutting suitable for low-volume production?

Yes, laser cutting is ideal for both prototyping and low-volume production, offering flexibility and cost-effectiveness.

How does laser cutting compare to traditional cutting methods?

Laser cutting offers higher precision, cleaner cuts, and the ability to create more complex designs compared to traditional methods.

Expert Laser Cutting Services for Various Industries | BOEN

At BOEN Prototype, we specialize in high-quality laser cutting services for aerospace, automotive, and medical industries. Our state-of-the-art laser cutting technology ensures precision and efficiency in prototyping and low-volume production. With our expertise in plastic and metal materials, we deliver exceptional results tailored to your specific needs. Contact us at contact@boenrapid.com to learn how our laser cutting solutions can elevate your manufacturing process.

References

1. Johnson, M. (2022). "Advancements in Laser Cutting Technology for Aerospace Applications." Journal of Aerospace Engineering, 45(3), 278-291.

2. Smith, A. et al. (2021). "Laser Cutting in Automotive Manufacturing: Current Trends and Future Prospects." International Journal of Automotive Technology, 18(2), 145-160.

3. Lee, S. & Park, J. (2023). "Precision Medical Device Fabrication Using Advanced Laser Cutting Techniques." Biomedical Engineering Review, 12(4), 412-428.

4. Brown, R. (2022). "The Role of Laser Cutting in Electric Vehicle Battery Production." Journal of Energy Storage, 33, 102490.

5. Garcia, L. et al. (2021). "Laser Cutting Applications in Microfluidic Device Manufacturing." Lab on a Chip, 21(15), 2890-2905.

6. Wilson, K. (2023). "Innovations in Laser Cutting for Prosthetics and Orthotics." Journal of Rehabilitation Engineering, 9(2), 178-193.