Understanding Custom Parts Manufacturing

The Essence of Custom Parts Manufacturing

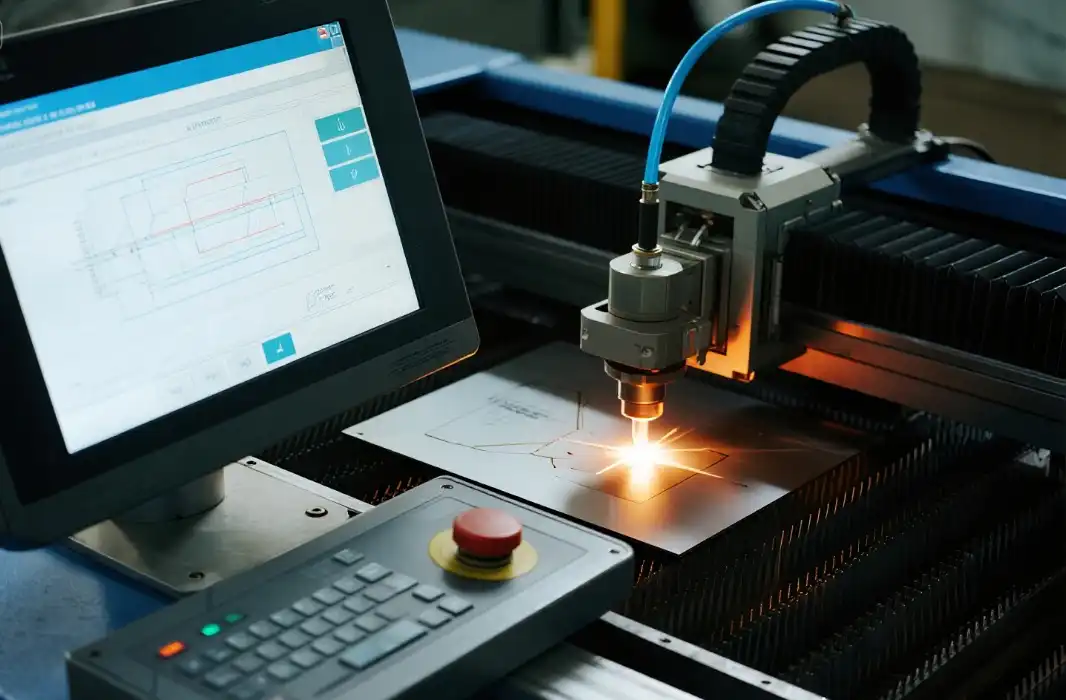

Custom parts manufacturing encompasses a range of traditional and advanced techniques designed to produce components tailored to specific requirements. This process involves converting raw materials into finished products using various methods such as CNC machining, injection molding, and sheet metal fabrication. These techniques allow for high precision, repeatability, and the ability to work with a wide array of materials, including metals, plastics, and composites.

Key Techniques in Custom Manufacturing

CNC machining stands out as a versatile method in custom parts manufacturing. It uses computer-controlled tools to cut, drill, and shape materials with exceptional accuracy. This technique is particularly valuable for creating complex geometries in metal parts. Injection molding, another cornerstone of custom manufacturing, excels in producing large quantities of identical plastic parts quickly and cost-effectively. For projects requiring metal components, sheet metal fabrication offers solutions through cutting, bending, and welding processes.

Advantages of Custom Manufacturing

One of the primary benefits of custom parts manufacturing is its ability to produce high-volume runs with consistent quality. This makes it ideal for industries like automotive and consumer electronics, where large quantities of identical parts are needed. Additionally, custom manufacturing allows for a wide range of material choices, including high-performance metals and plastics that may not be suitable for 3D printing. The surface finish and structural integrity of parts produced through these methods often surpass those of 3D printed components, especially for applications requiring high strength or precise tolerances.

Exploring the World of 3D Printing

The Revolution of Additive Manufacturing

3D printing, also known as additive manufacturing, has revolutionized the prototyping and small-scale production landscape. This technology builds objects layer by layer, allowing for the creation of complex shapes that would be challenging or impossible to produce with traditional manufacturing methods. 3D printing encompasses various techniques, including Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS), each with its unique strengths and material capabilities.

Applications and Advantages of 3D Printing

The most significant advantage of 3D printing lies in its rapid prototyping capabilities. Designers and engineers can quickly iterate on their ideas, producing physical models in a matter of hours. This speed is particularly valuable in industries like medical device development and aerospace, where testing multiple design variations is crucial. 3D printing also excels in producing customized, one-off parts, a key aspect of custom parts manufacturing, making it ideal for specialized applications or low-volume production runs. The technology's ability to create intricate internal structures and lattices opens up new possibilities in lightweight design and material optimization.

Limitations and Considerations

While 3D printing offers unparalleled flexibility in design, it does have limitations. The material properties of 3D printed parts may not always match those of traditionally manufactured components, particularly in terms of strength and durability. Surface finish can also be a concern, often requiring post-processing for a polished appearance. Additionally, the production speed of 3D printing becomes a limitation for larger volume runs, where traditional manufacturing methods like injection molding become more economical and efficient.

Choosing Between Custom Manufacturing and 3D Printing

Factors Influencing the Decision

Selecting between custom parts manufacturing and 3D printing depends on various factors. Production volume is a critical consideration; custom manufacturing typically becomes more cost-effective for larger quantities, while 3D printing is often preferable for smaller runs or prototypes. The complexity of the part's geometry also plays a role. 3D printing excels in creating intricate designs, while custom manufacturing techniques like CNC machining offer superior precision for less complex shapes. Material requirements are another crucial factor, as custom manufacturing provides a broader range of material options, including high-performance metals and plastics.

Industry-Specific Considerations

Different industries have varying needs that influence the choice between custom parts manufacturing and 3D printing. In the automotive sector, custom parts manufacturing is often preferred for its ability to produce durable, high-precision parts at scale. However, 3D printing finds its place in creating prototypes and customized components. The medical industry leverages both methods; custom parts manufacturing for large-scale production of standardized devices, and 3D printing for patient-specific implants and anatomical models. Aerospace companies utilize custom parts manufacturing for critical, high-stress components, while employing 3D printing for rapid prototyping and creating lightweight, complex structures.

Hybrid Approaches and Future Trends

As manufacturing technologies evolve, the lines between custom parts manufacturing and 3D printing are blurring. Hybrid approaches that combine the strengths of both methods are emerging. For instance, 3D printing might be used to create complex molds for injection molding, marrying the design freedom of additive manufacturing with the production efficiency of traditional techniques. Looking ahead, advancements in materials science and manufacturing technologies are likely to further expand the capabilities of both custom manufacturing and 3D printing, offering even more options for product developers and manufacturers across industries.

Conclusion

Custom parts manufacturing and 3D printing each offer unique advantages in the production landscape. While custom manufacturing excels in high-volume production, material versatility, and precision, 3D printing shines in rapid prototyping, complex geometries, and customization. The choice between these methods depends on factors such as production volume, part complexity, material requirements, and industry-specific needs. As technologies continue to advance, we can expect to see more innovative applications and hybrid approaches that leverage the strengths of both methods. Understanding these key differences empowers businesses to make informed decisions, optimizing their production processes for efficiency, quality, and cost-effectiveness.

FAQs

Which method is faster, custom parts manufacturing or 3D printing?

For small quantities or prototypes, 3D printing is typically faster. However, for larger production runs, custom manufacturing methods like injection molding are more efficient.

Can 3D printing produce parts as strong as those made through custom manufacturing?

While 3D printing technology is improving, custom manufactured parts often have superior strength and durability, especially for metal components.

Is custom manufacturing more expensive than 3D printing?

For small quantities, 3D printing is often more cost-effective. However, custom manufacturing becomes more economical for larger production runs due to economies of scale.

Expert Custom Parts Manufacturing Solutions | BOEN

At BOEN Rapid, we specialize in delivering top-tier custom parts manufacturing solutions for industries ranging from automotive to aerospace. Our state-of-the-art CNC machining, injection molding, and sheet metal fabrication capabilities ensure precision and quality in every component we produce. With rapid turnaround times and global shipping, we're your trusted partner for bringing your designs to life. Experience the BOEN difference in custom parts manufacturing today. Contact us at contact@boenrapid.com to discuss your project needs.

References

1. Smith, J. (2022). Advanced Manufacturing Techniques: A Comprehensive Guide.

2. Johnson, A. et al. (2021). Comparing 3D Printing and Traditional Manufacturing Methods in Aerospace Applications.

3. Brown, T. (2023). The Future of Custom Parts Manufacturing: Trends and Innovations.

4. Lee, S. (2022). Material Science Advancements in Additive Manufacturing.

5. Wilson, R. (2021). Cost-Benefit Analysis of 3D Printing vs. Traditional Manufacturing in the Automotive Industry.

6. Taylor, M. (2023). Hybrid Manufacturing: Combining the Best of 3D Printing and Custom Parts Production.