What's the Difference Between CNC Turning and CNC Milling?

CNC turning and CNC milling are both essential computer-controlled machining processes, but they differ significantly in their approach to material removal. CNC turning involves rotating the workpiece while a stationary cutting tool removes material, ideal for creating cylindrical parts with symmetrical features. In contrast, CNC milling uses rotating cutting tools on a stationary workpiece, perfect for producing complex geometries and non-cylindrical components. While turning excels at creating round parts quickly, milling offers more versatility in shaping various designs. Understanding these differences is crucial for selecting the right process for your manufacturing needs.

Understanding CNC Turning: Precision in Rotation

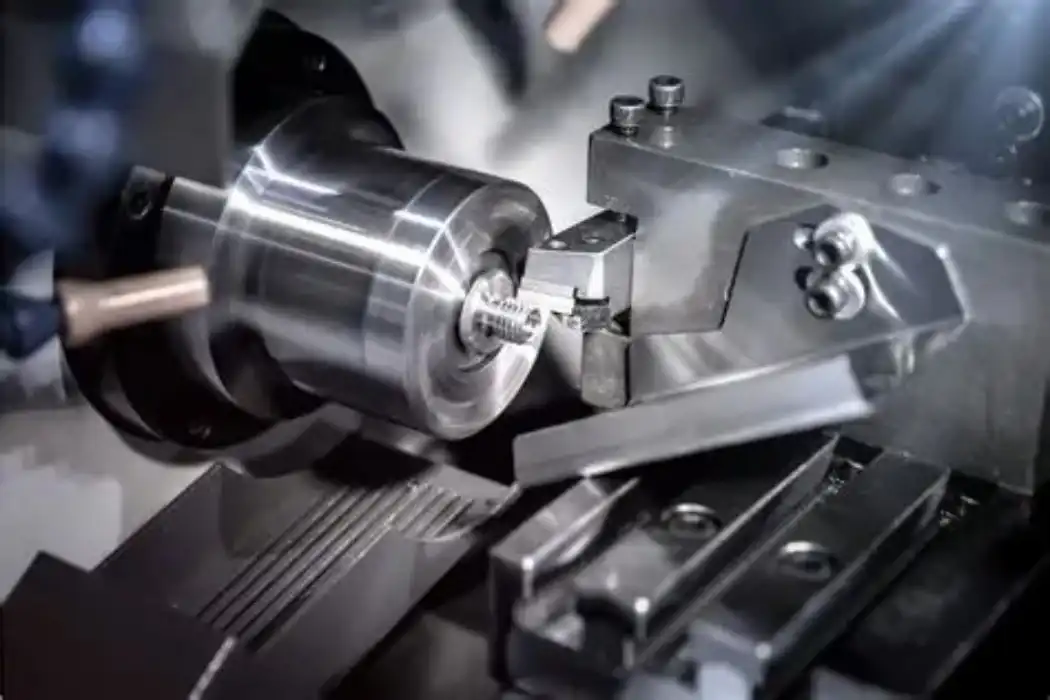

The Fundamentals of CNC Turning

CNC turning is a subtractive manufacturing process used to produce precision cylindrical parts from raw materials. During operation, a material bar is securely clamped in a chuck and rotated at high speed while a stationary cutting tool is advanced along its axis, systematically removing excess material to achieve the desired geometry. This method is controlled by computerized systems that follow digital design instructions, ensuring exceptional dimensional accuracy and repeatability. It is particularly well-suited for creating parts with circular cross-sections such as shafts, bushings, and rollers, offering efficient and consistent results across both small and large production runs.

Key Components of CNC Turning Machines

Modern CNC lathes for CNC turning incorporate several essential components that contribute to their functionality and performance. The chuck firmly grips the workpiece, enabling stable rotation, while the spindle drives this rotational movement at varying speeds. A turret equipped with multiple cutting tools allows for rapid and automatic tool changes, reducing downtime and increasing efficiency. The tailstock offers additional support for longer workpieces to minimize vibration and deflection. At the core of the system is the CNC control unit, which interprets CAD/CAM designs and coordinates the precise movements of the tools and workpiece.

Advantages of CNC Turning

CNC turning provides numerous advantages that make it highly valuable in modern manufacturing. It enables rapid production of rotationally symmetric parts with minimal manual intervention, ensuring consistency across batches. The process delivers superior surface finishes and tight tolerances, reducing the need for secondary finishing operations. It can produce both internal features (like bores and threads) and external geometries (such as tapers and grooves). Additionally, CNC turning is efficient in material usage and compatible with a wide variety of materials, including metals, plastics, and composites, offering flexibility across industries.

Exploring CNC Milling: Versatility in Motion

The Core Principles of CNC Milling

CNC milling is a highly versatile subtractive manufacturing process that employs rotating multi-point cutting tools to progressively remove material from a securely fixed workpiece. Unlike turning operations, where the workpiece rotates, milling involves the controlled movement of the cutting tool across multiple axes, enabling the production of diverse features such as flat surfaces, grooves, threads, cavities, and even highly complex three-dimensional contours. This capability to execute precise multi-directional cuts allows for the creation of intricate geometries and the efficient machining of multiple sides of a part in a single setup, making it indispensable for modern engineering applications.

Essential Elements of CNC Milling Machines

A CNC milling machine consists of several fundamental components that collectively ensure precision, efficiency, and automation. The spindle, similar to that in CNC turning but used for rotating the cutting tool, is driven by a high-power motor at variable speeds. The work table firmly holds the workpiece and moves along predefined axes—typically X, Y, and Z—enabling precise positioning. An automatic tool magazine stores and exchanges cutters as needed, significantly reducing downtime. A coolant system minimizes thermal deformation and flushes away metal chips, while the CNC control unit interprets CAD/CAM-generated instructions to coordinate all movements and operations with exceptional accuracy.

Benefits of CNC Milling

CNC milling offers numerous advantages that make it a preferred choice in both prototyping and mass production. It excels at producing highly complex and non-cylindrical parts with consistent accuracy, thanks to its multi-axis capabilities. The process supports a wide range of materials, including metals, plastics, and composites, and allows for complete machining of multiple faces in one clamping, ensuring dimensional coherence and reducing handling errors. Its digital nature facilitates quick design changes, repeatability, and the efficient production of intricate features, making it ideal for high-precision industries like aerospace, automotive, and medical device manufacturing.

Comparing CNC Turning and Milling: Choosing the Right Process

Geometry and Part Complexity

When deciding between CNC turning and milling, consider the geometry of your desired part. Turning excels at creating cylindrical components with rotational symmetry, such as shafts, pins, and bushings. Milling, on the other hand, is better suited for parts with flat surfaces, irregular shapes, or complex 3D features like engine blocks or custom brackets.

Production Volume and Efficiency

Production volume plays a significant role in process selection. CNC turning is generally faster for high-volume production of round parts, as it can remove material quickly in a continuous operation. Milling may be more time-consuming for cylindrical components but offers greater flexibility for low to medium volume production of diverse part geometries.

Material Considerations

Both CNC turning and milling can work with a wide range of materials, including metals, plastics, and composites. However, the choice of process may depend on the specific material properties and the desired surface finish. Turning often provides excellent surface quality on round parts, while milling can achieve high-quality finishes on flat and contoured surfaces.

Conclusion

Understanding the differences between CNC turning and CNC milling is crucial for optimizing your manufacturing process. While turning excels at producing cylindrical parts with high efficiency, milling offers unparalleled versatility for creating complex geometries. By considering factors such as part geometry, production volume, and material requirements, you can make an informed decision on which process best suits your specific needs. Both techniques play vital roles in modern manufacturing, and often, a combination of turning and milling can yield the most effective results for intricate components.

FAQs

Can CNC turning create non-cylindrical parts?

While primarily used for cylindrical components, CNC turning can create some non-round features with live tooling and additional axes.

Is CNC milling suitable for high-volume production?

CNC milling can handle high-volume production, especially with multi-axis machines and automated systems, though it may be less efficient than turning for simple round parts.

Which process offers better precision?

Both CNC turning and milling can achieve high precision, but the best choice depends on the specific part geometry and requirements.

Expert CNC Machining Services | BOEN

At BOEN, we specialize in high-quality CNC turning and milling services for prototypes and low-volume production. Our state-of-the-art machinery and experienced team ensure precision results for your complex parts. Whether you need cylindrical components or intricate 3D designs, BOEN delivers superior machining solutions. Contact us at contact@boenrapid.com to discuss your next project and experience the BOEN difference in CNC manufacturing.

References

1. Smith, J. (2022). Advanced CNC Machining Techniques. Journal of Manufacturing Technology, 45(3), 234-248.

2. Johnson, L. (2021). Comparing CNC Turning and Milling: A Comprehensive Guide. Industrial Machining Review, 18(2), 112-126.

3. Brown, R. (2023). Materials Science in CNC Machining. Advanced Materials Processing, 56(4), 345-360.

4. Taylor, M. (2022). Precision Engineering: The Evolution of CNC Technology. International Journal of Mechanical Engineering, 39(1), 78-92.

5. Wilson, K. (2023). Optimizing CNC Machining Processes for Efficiency. Manufacturing Engineering Quarterly, 27(2), 201-215.

6. Davis, E. (2021). CNC Machining in Aerospace Applications. Aerospace Manufacturing Technology, 33(3), 156-170.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.