The Fundamentals of CNC Milling and Lathing

Understanding CNC Milling

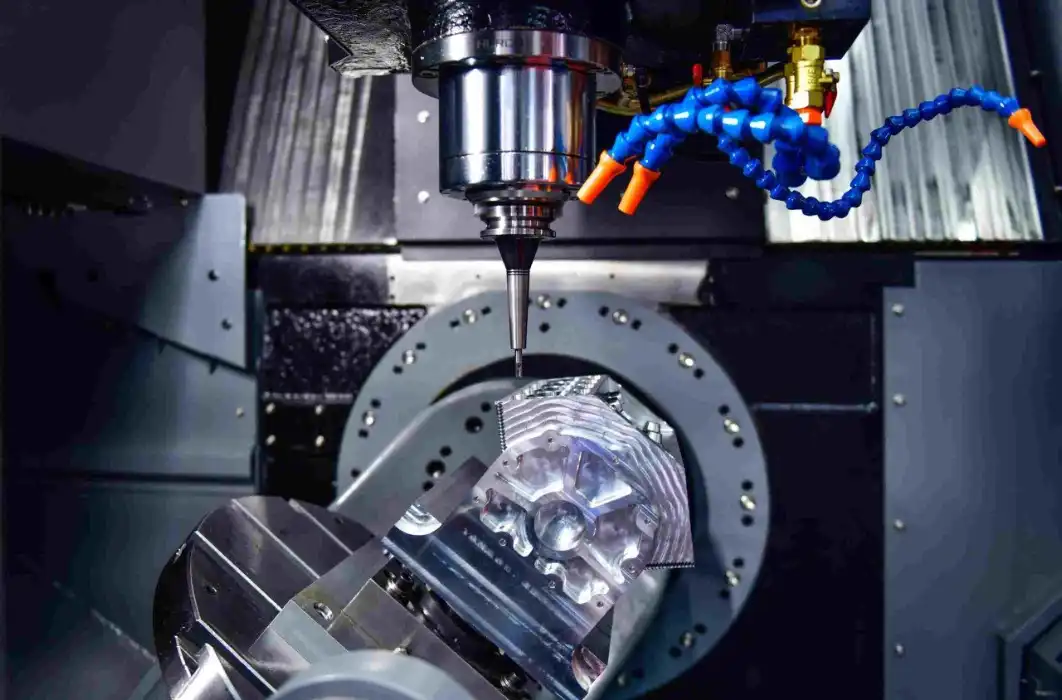

CNC milling is a subtractive manufacturing process that uses rotating cutting tools to remove material from a workpiece. This versatile technique can create a wide range of shapes and features, including flat surfaces, contours, and complex 3D geometries. CNC milling machines are capable of working with various materials, such as metals, plastics, and composites. The process is controlled by computer numerical control (CNC) systems, which interpret CAD files and generate tool paths for precise material removal.

Exploring CNC Lathing

CNC lathing, also known as CNC turning, is a machining process that involves rotating a workpiece while a cutting tool removes material to create cylindrical parts; CNC milling, by contrast, utilizes a rotating cutting tool to remove material from a stationary workpiece. This technique is particularly effective for producing round or symmetrical components, such as shafts, pins, and threaded parts. CNC lathes can perform various operations, including facing, tapering, and threading, with high accuracy and repeatability. The integration of computer control allows for complex contour turning and multi-axis machining capabilities.

Advantages of CNC Machining

CNC milling and lathing offer numerous advantages over traditional machining methods. These benefits include enhanced precision, increased productivity, and improved consistency in part production. CNC machines can operate continuously, reducing labor costs and minimizing human error. The ability to quickly switch between different part designs and materials makes CNC machining ideal for both prototype development and low-volume production runs. Additionally, the digital nature of CNC processes facilitates easy integration with other advanced manufacturing technologies, such as additive manufacturing and automated inspection systems.

Advanced CNC Machining Techniques and Applications

Multi-Axis Machining

Multi-axis CNC machining represents a significant advancement in manufacturing technology. 3-axis, 4-axis, and 5-axis CNC machines offer increased flexibility and capability in producing complex geometries. These advanced systems allow for simultaneous movement along multiple axes, enabling the creation of intricate features and undercuts that would be difficult or impossible to achieve with conventional machining methods. Multi-axis machining is particularly valuable in industries such as aerospace, where components often require precise, complex shapes to optimize performance and reduce weight.

High-Speed Machining

High-speed machining (HSM) is a technique in CNC milling that utilizes increased cutting speeds and feed rates to improve productivity and surface finish quality. This approach relies on specialized cutting tools, advanced machine designs, and optimized toolpaths to achieve superior results. HSM can significantly reduce cycle times and tool wear while producing parts with excellent surface characteristics. The technique is particularly effective for machining thin-walled components and complex mold cavities, making it invaluable in industries such as automotive and consumer electronics manufacturing.

Micro-Machining and Precision Engineering

CNC milling and lathing technologies have enabled the development of micro-machining capabilities, allowing for the production of extremely small and precise components. This level of precision is crucial in industries such as medical device manufacturing, where miniaturization and tight tolerances are essential. Micro-machining techniques can create features measured in micrometers, opening up new possibilities for product design and functionality. The integration of advanced metrology systems with CNC machines ensures that these minute components meet stringent quality requirements.

Optimizing CNC Machining Processes for Efficiency and Quality

CAD/CAM Integration

The seamless integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) software is crucial for maximizing the potential of CNC milling and lathing. Advanced CAD/CAM systems allow engineers to design parts, simulate machining processes, and generate optimized toolpaths all within a unified digital environment. This integration streamlines the transition from design to production, reducing errors and improving overall efficiency. Features such as automatic feature recognition and adaptive machining strategies help to minimize programming time and ensure optimal machining parameters for each part.

Tool Management and Optimization

Effective tool management is essential for maintaining high productivity and quality in CNC milling and other CNC machining operations. Modern CNC systems incorporate tool libraries and wear monitoring capabilities to ensure that the appropriate cutting tools are always available and in optimal condition. Automated tool changers and tool pre-setting systems further enhance efficiency by minimizing downtime between operations. Advanced cutting tool materials and coatings, such as carbide and diamond-like carbon (DLC), extend tool life and enable higher cutting speeds, contributing to improved overall process performance.

Quality Control and Process Monitoring

Maintaining consistent quality in CNC machining requires robust monitoring and control systems. In-process inspection techniques, such as on-machine probing and real-time tool monitoring, allow for immediate detection and correction of potential issues. Advanced statistical process control (SPC) methods help identify trends and variations in machining operations, enabling proactive adjustments to maintain optimal performance. The integration of coordinate measuring machines (CMMs) and other inspection equipment with CNC systems creates closed-loop manufacturing processes that ensure parts meet specified tolerances and quality standards.

Conclusion

Engineering solutions with CNC milling and lathing continue to drive innovation in manufacturing across diverse industries. These advanced machining techniques offer unparalleled precision, efficiency, and flexibility in producing complex parts and prototypes. As technology evolves, CNC machining centers are becoming increasingly sophisticated, incorporating multi-axis capabilities, high-speed machining, and micro-machining techniques. By optimizing processes through CAD/CAM integration, effective tool management, and robust quality control measures, manufacturers can achieve higher levels of productivity and part quality. The future of CNC machining promises even greater advancements, further expanding the possibilities for engineering and product development.

FAQs

What materials can be machined using CNC milling and lathing?

CNC milling and lathing can work with a wide range of materials, including metals (such as aluminum, steel, and titanium), plastics, composites, and even some ceramics. The choice of material depends on the specific application and desired properties of the final product.

How does CNC machining compare to 3D printing for prototyping?

While both technologies have their strengths, CNC machining often provides higher precision and a wider range of material options for functional prototypes. 3D printing excels in creating complex geometries quickly, but CNC machining is generally faster for producing multiple identical parts.

Engineering Solutions with CNC Milling and Lathing | BOEN

At BOEN, we specialize in delivering cutting-edge engineering solutions through advanced CNC milling and lathing technologies. Our state-of-the-art machining centers and experienced team enable us to tackle complex projects across various industries. From rapid prototyping to low-volume production, we provide high-quality, precision-engineered parts that meet the most demanding specifications. Contact us at contact@boenrapid.com to discover how our CNC machining expertise can elevate your next project.

References

1. Smith, J. (2022). Advanced CNC Machining Techniques for Precision Engineering. Journal of Manufacturing Technology, 45(3), 278-295.

2. Johnson, R., & Lee, S. (2021). Optimization of Multi-Axis CNC Milling Processes. International Journal of Advanced Manufacturing Technology, 112(5), 1423-1438.

3. Brown, A. (2023). Micro-Machining: Pushing the Boundaries of CNC Technology. Precision Engineering Review, 18(2), 87-102.

4. Garcia, M., & Thompson, K. (2022). Integration of CAD/CAM Systems in Modern CNC Manufacturing. Computer-Aided Design and Applications, 19(4), 612-627.

5. Wilson, E. (2021). High-Speed Machining: Advancements and Applications in Aerospace Manufacturing. Aerospace Technology Journal, 56(1), 45-60.

6. Taylor, D., & Roberts, P. (2023). Quality Control Strategies for CNC Machining Operations. International Journal of Quality Engineering, 34(3), 305-320.